When a problem arises, you would ask questions about why it occurred, and based on the answers, you could come to a solution. A very effective way of going about this is through the 5 Whys method. This is a repetitive interrogation technique used to examine the cause-and-effect relationships that underlie a specific problem. It typically involves the use of a 5 whys root cause analysis template. Determining the root cause of a problem or defect by repeating the question “Why?” is the main goal of this technique. Each answer will form the basis of your next question until you resolve the issue.

Table of Contents

- 1 5 Whys Templates

- 2 What is the 5 Whys technique?

- 3 5 Whys Root Cause Analysis Templates

- 4 What are the 5 Whys questions?

- 5 What is the purpose of the 5 Whys technique?

- 6 Using the technique in customer feedback teams

- 7 5 Whys Worksheets

- 8 Does it have any limitations?

- 9 How do you document 5 Whys?

- 10 5 Whys Diagrams

- 11 How to use the 5 whys template?

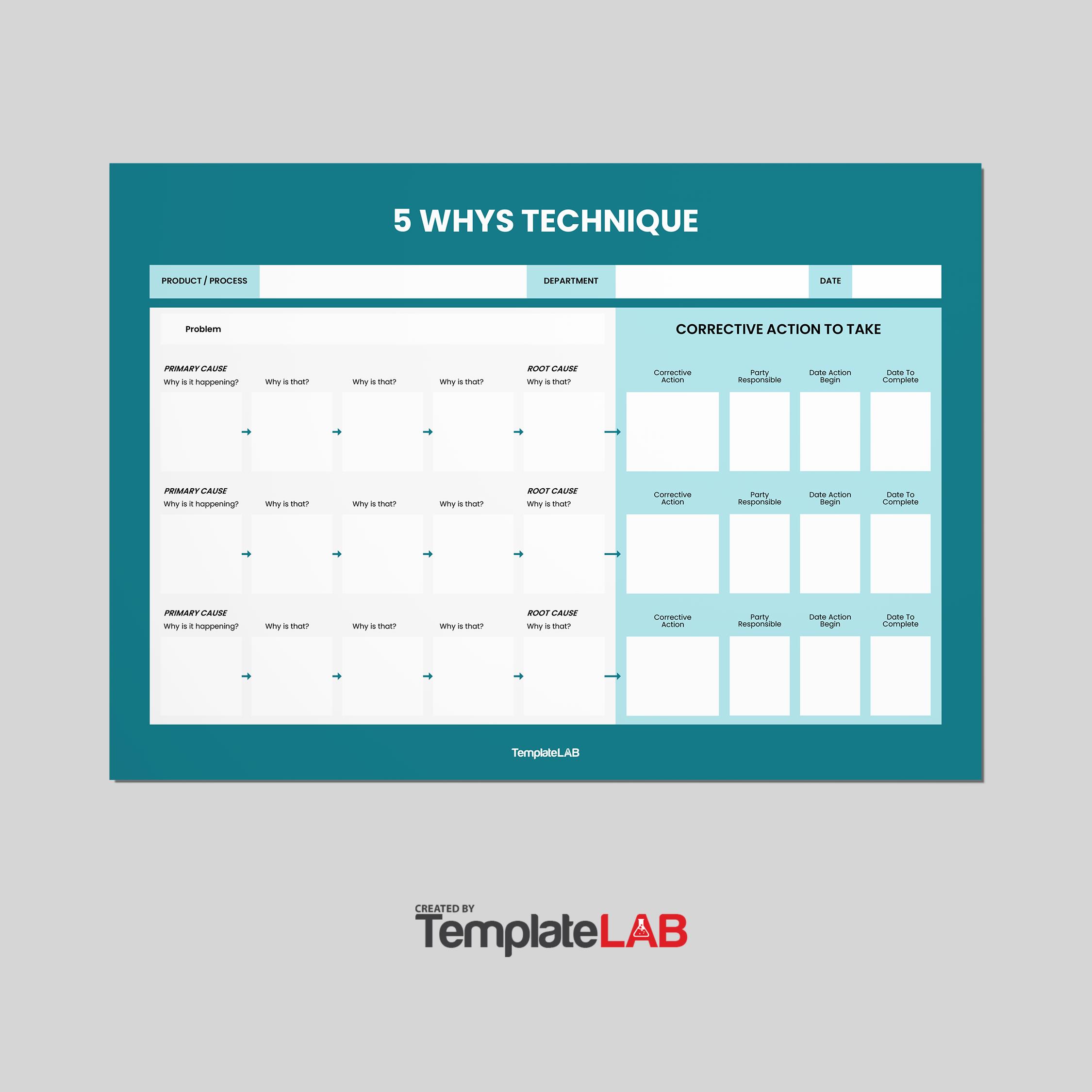

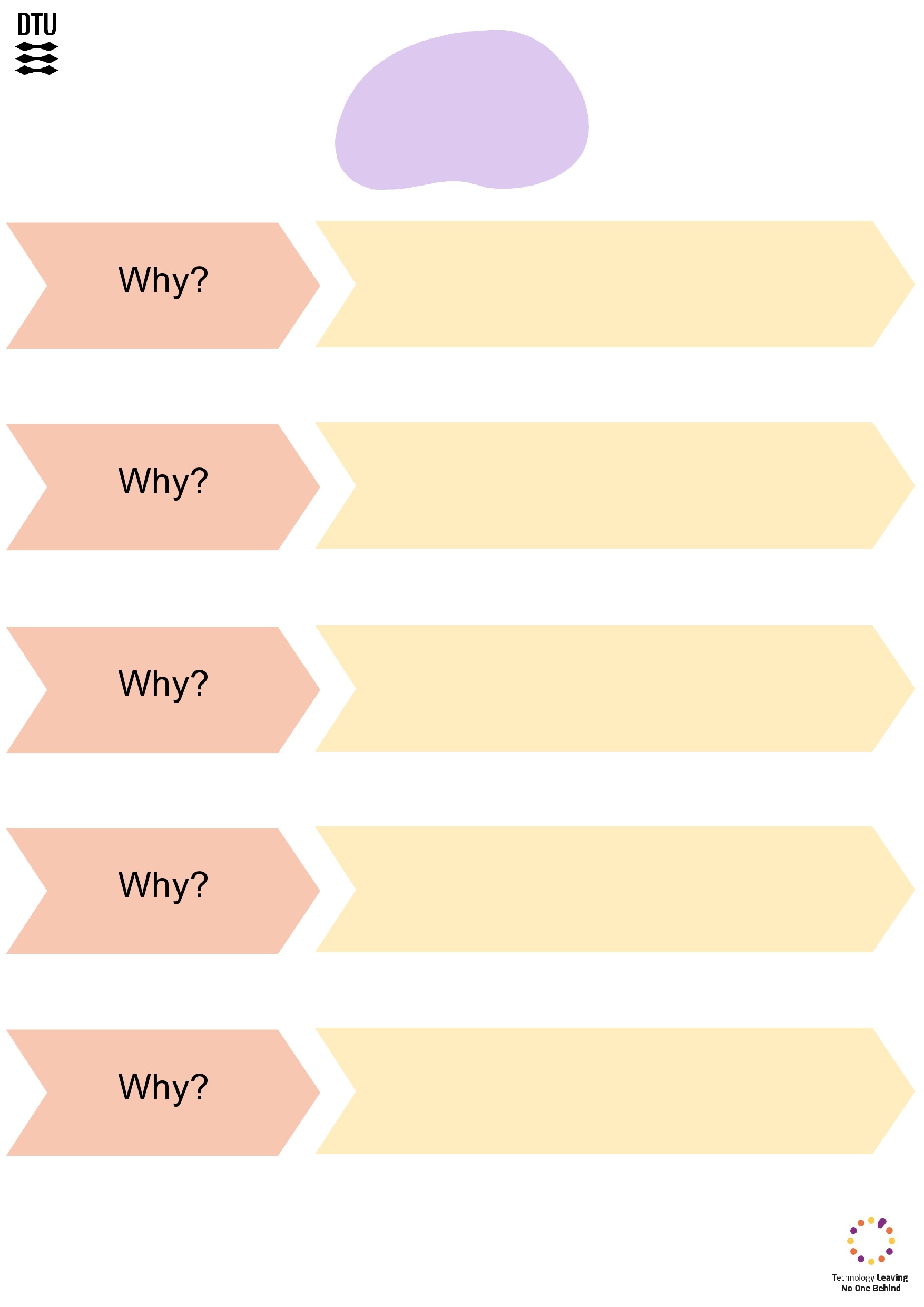

5 Whys Templates

What is the 5 Whys technique?

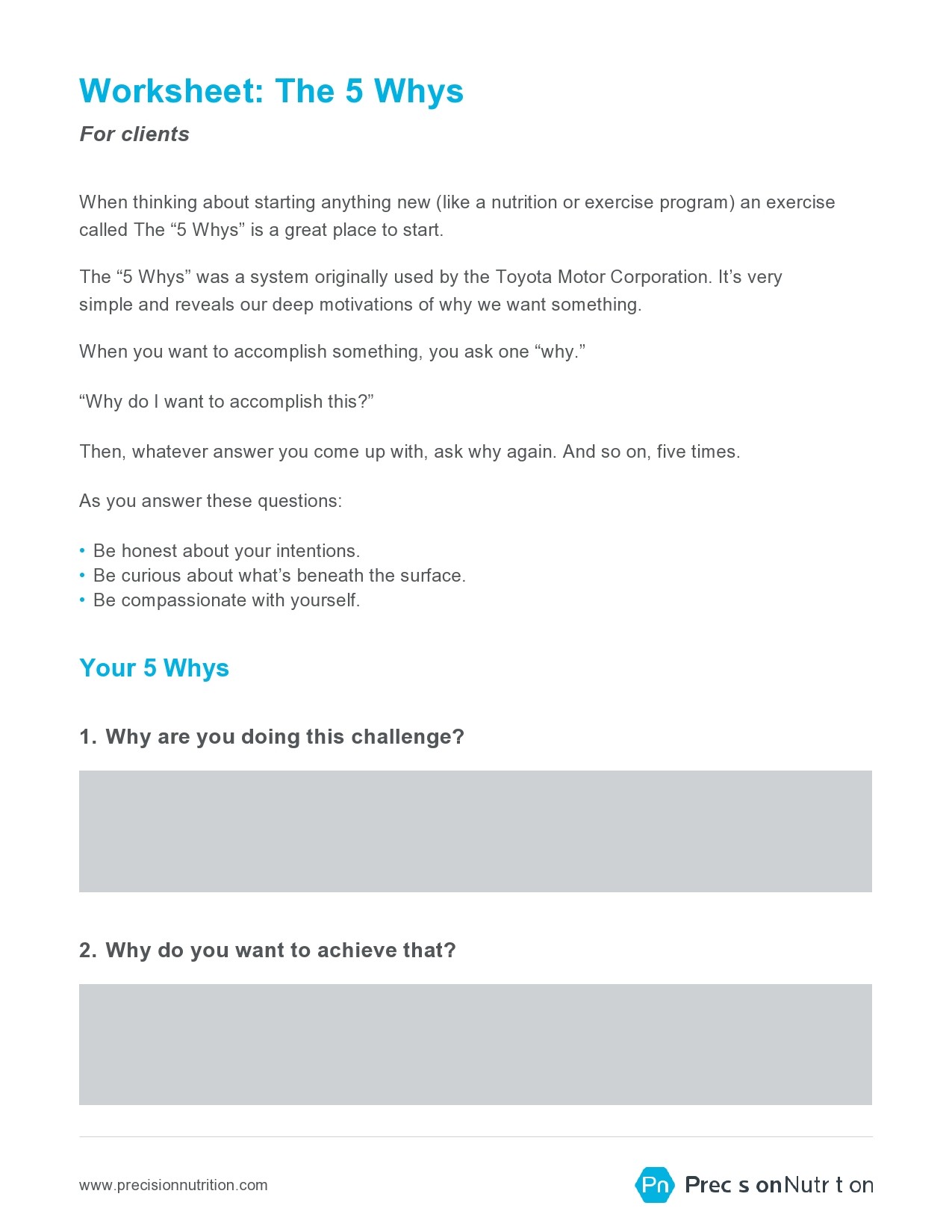

A 5 whys example template is a simple tool for brainstorming used to help identify the root cause of an issue. It starts with an issue where you ask the question “Why?” until you narrow the answers down to a single issue upon which you can concentrate your attention and efforts. You would use this technique to get to the root of an issue.

It involves a very simple approach – ask why the problem happened, then ask four times more. It’s simple but it does require the whole process. Toyota pioneered this technique as a crucial component of its training for problem-solving. By repeating the question 5 times, it will become easier to arrive at the root of the issue so you can find the best solution.

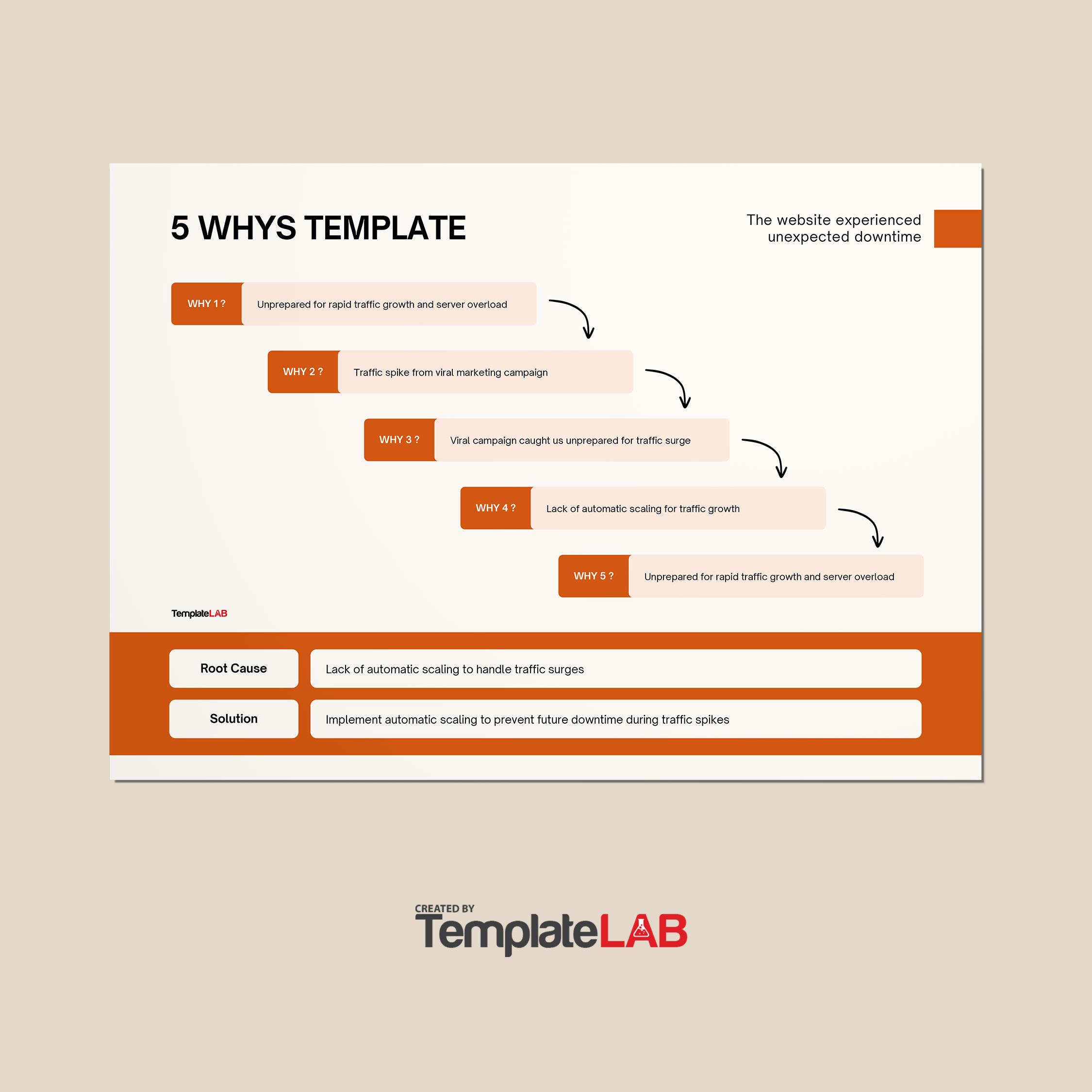

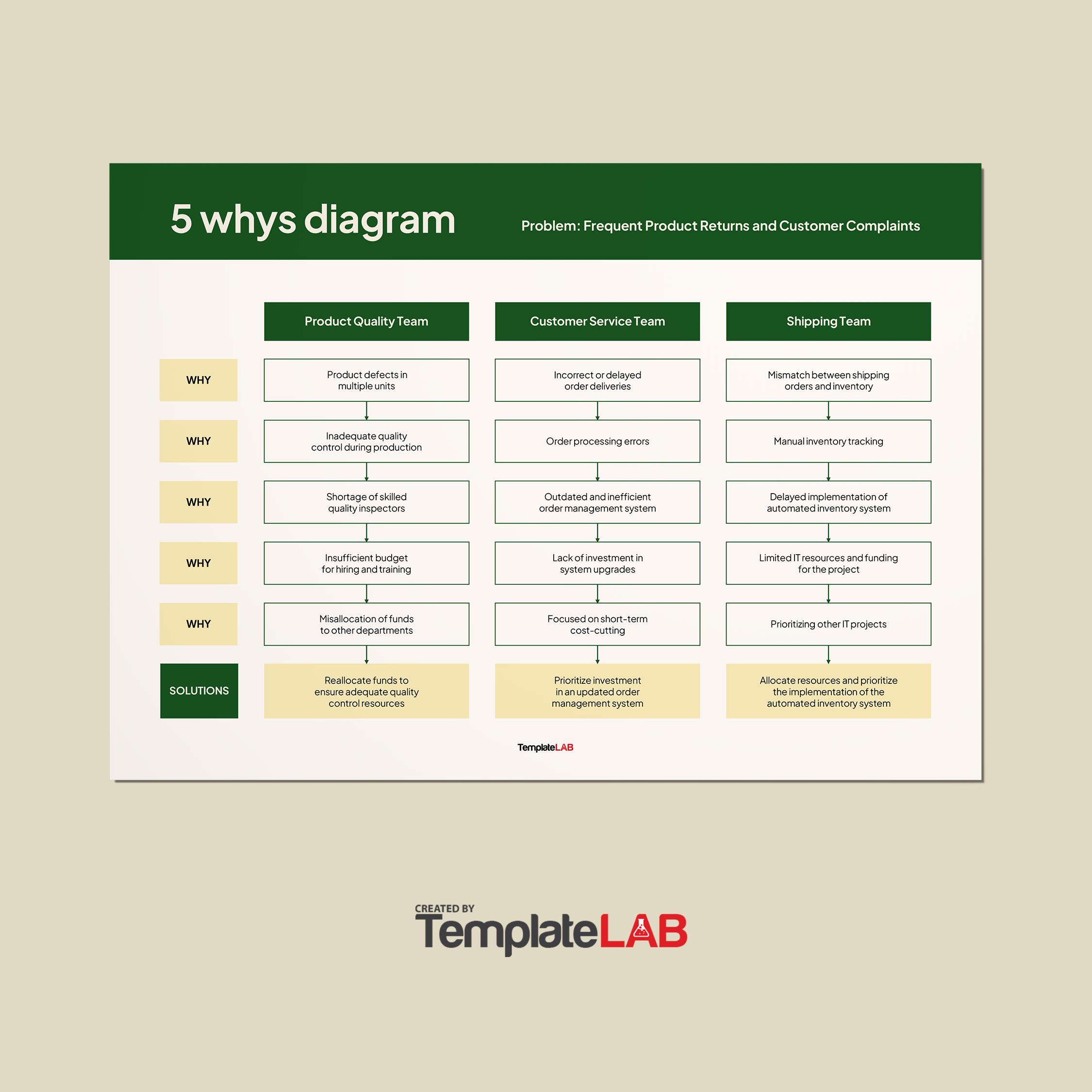

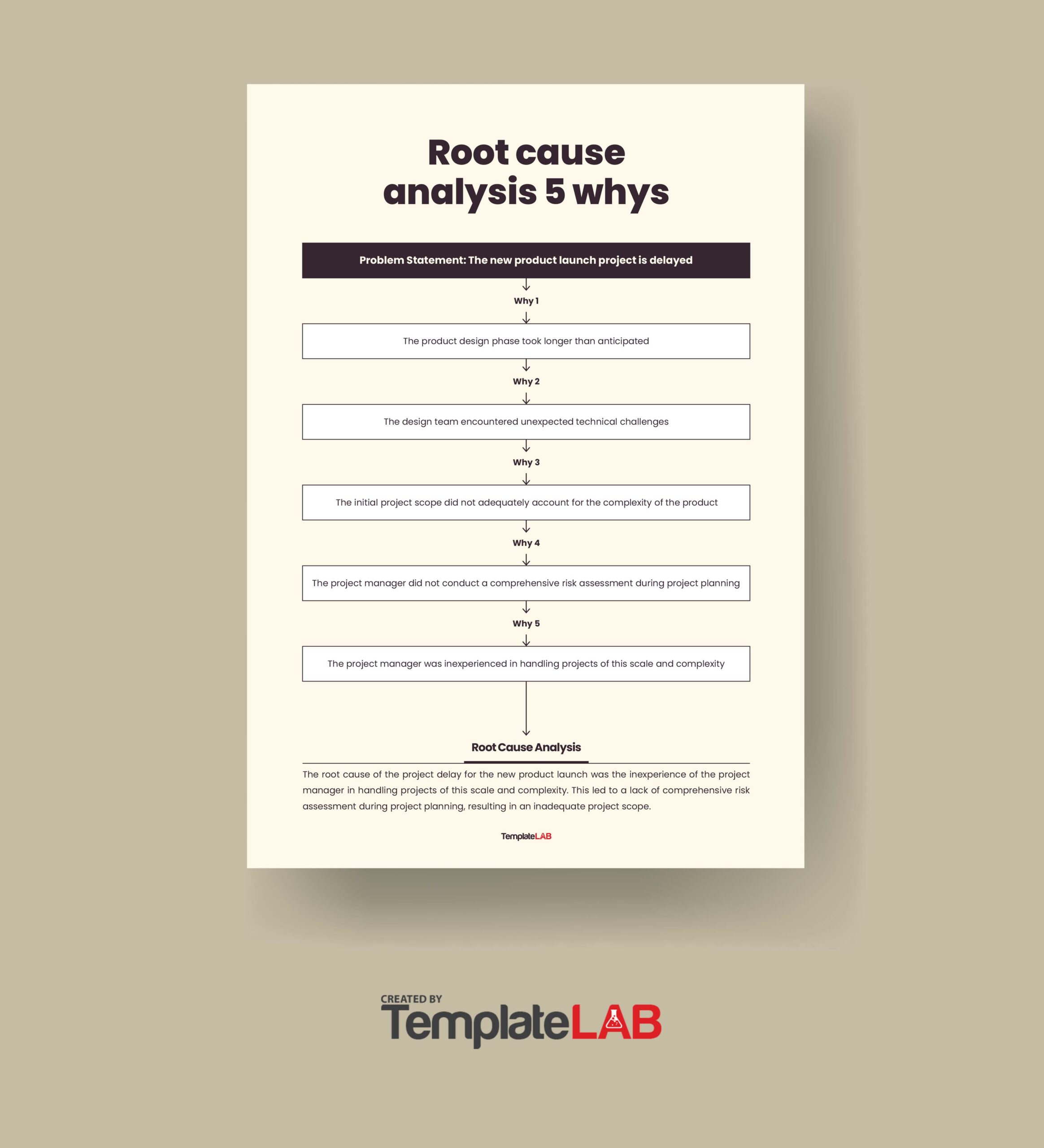

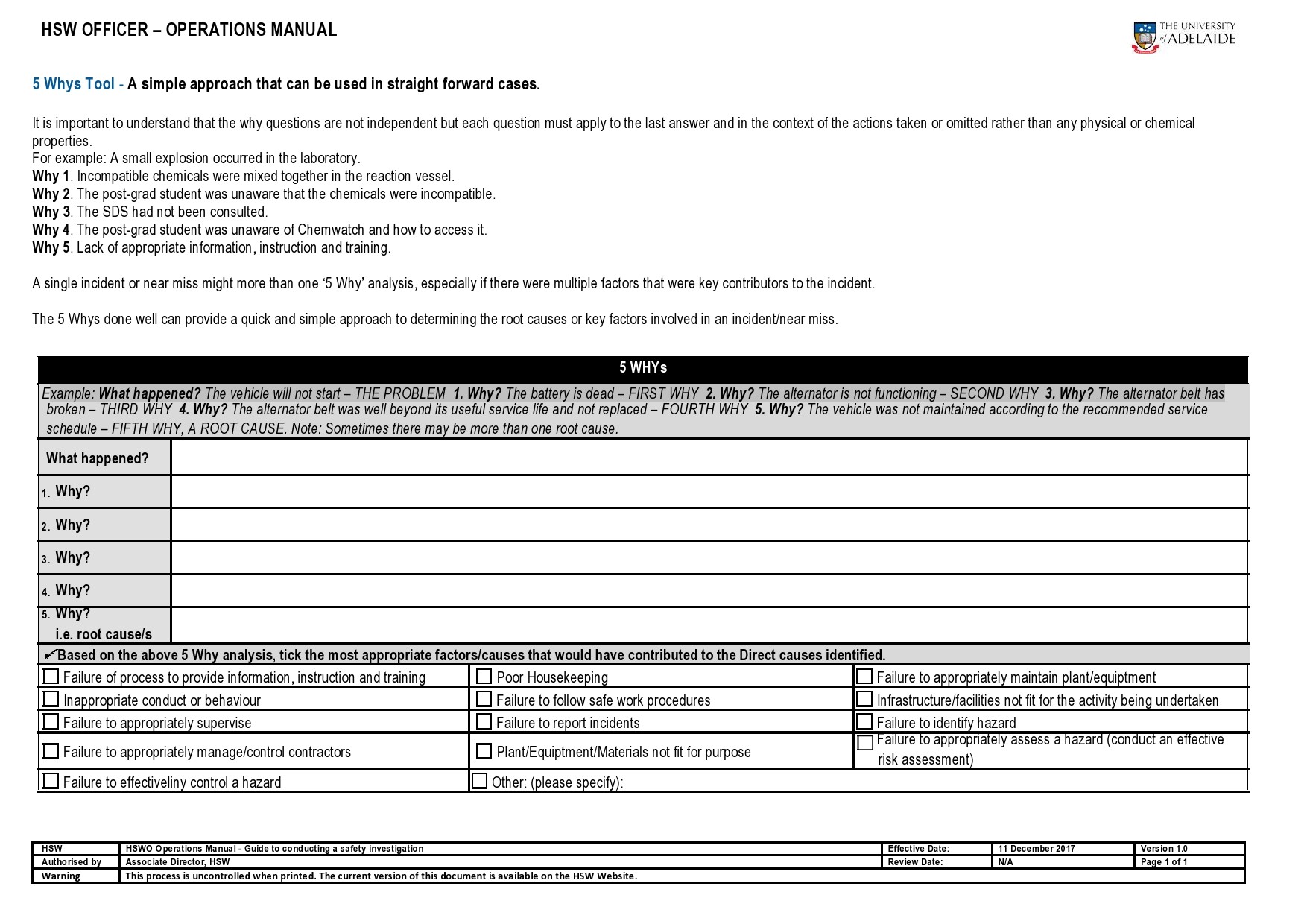

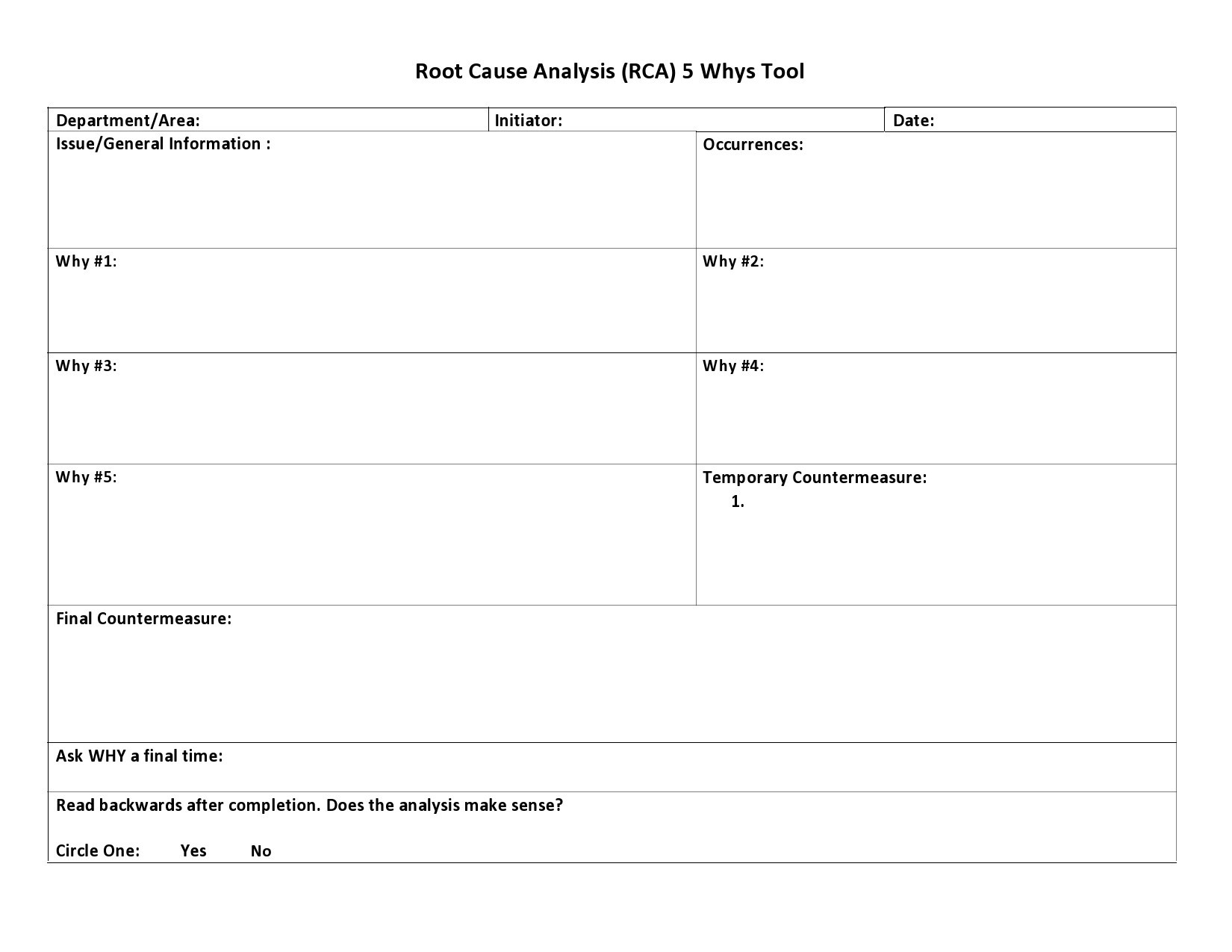

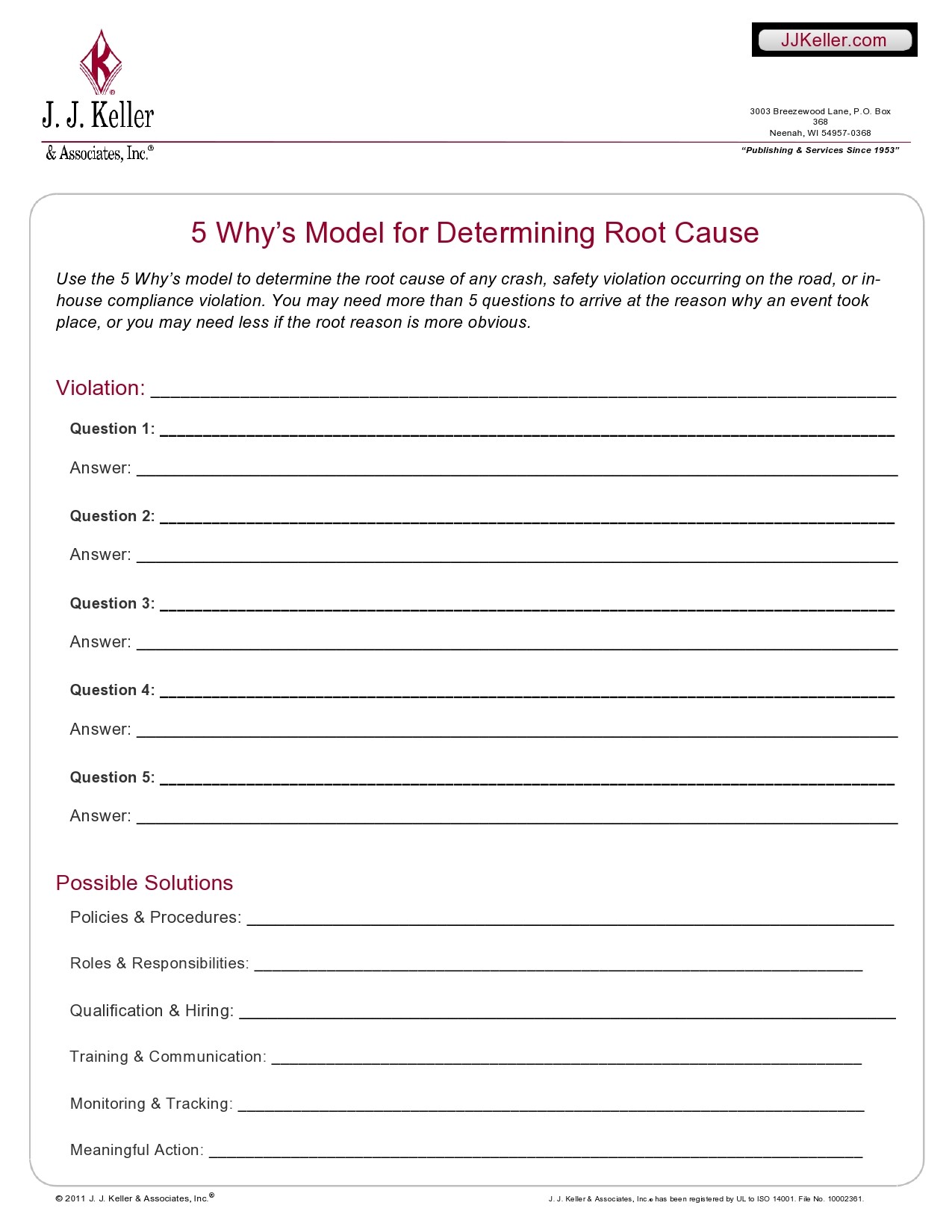

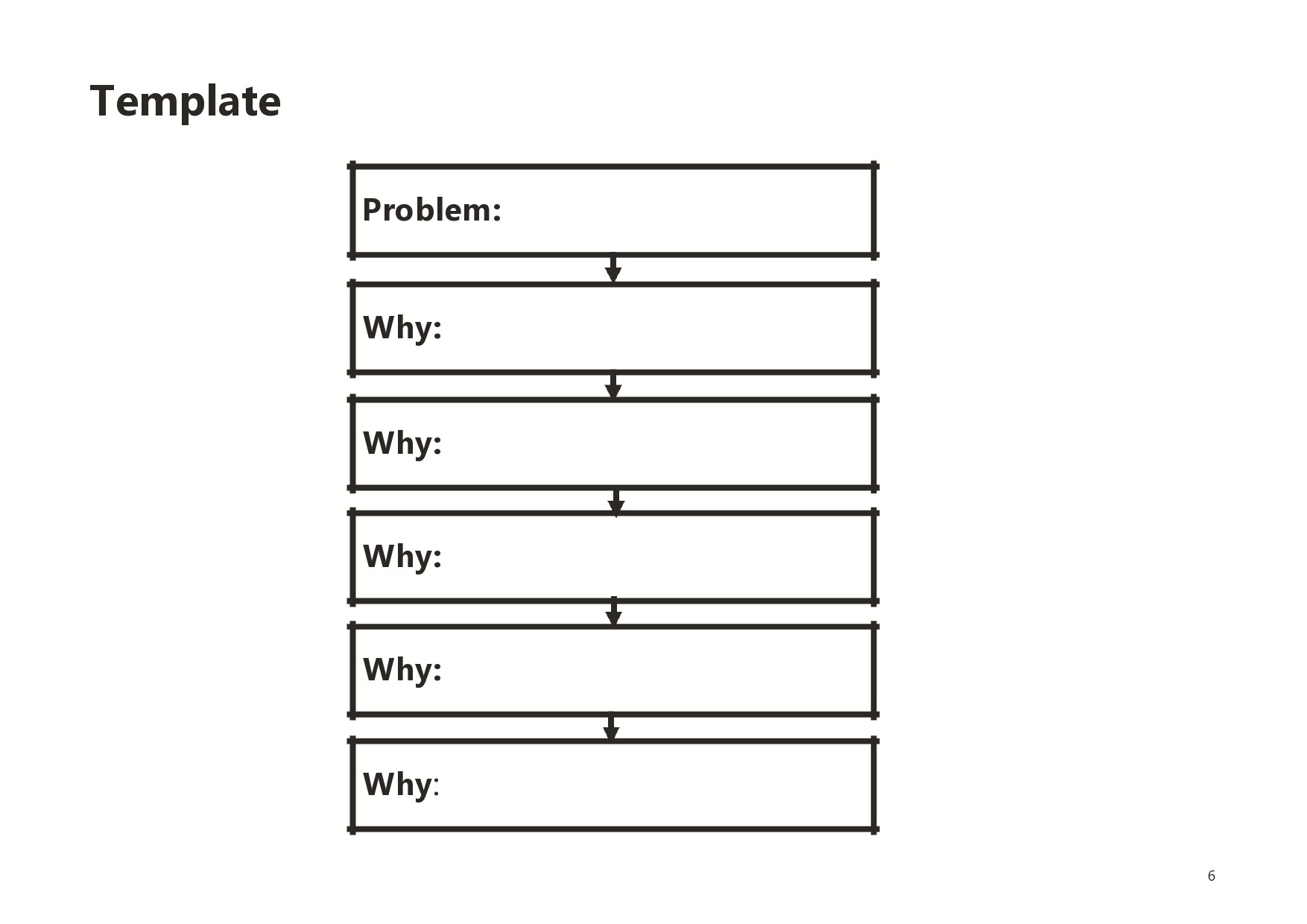

5 Whys Root Cause Analysis Templates

What are the 5 Whys questions?

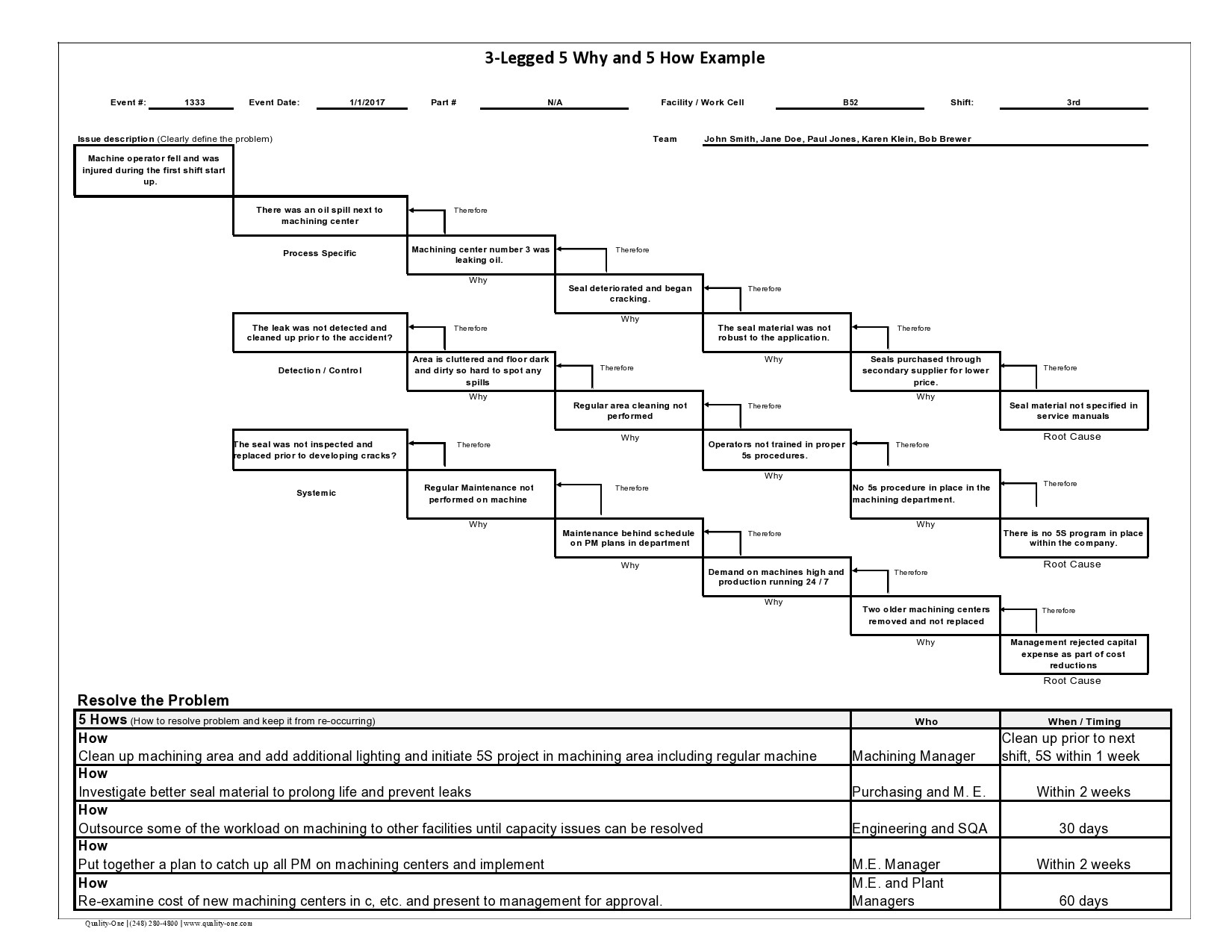

The main concept behind the 5 Whys technique is in its name. You ask the question 5 times to understand why an issue happened. The developer of this simple technique was Taiichi Ohno, the founder of the Toyota Production System. They used this technique to observe the production floor without having any preconceptions. Then they asked the “why” question repeatedly about every issue. To help others understand this technique, Ohno used a malfunctioning robot, then asked the following questions:

- Why did the robot stop? The answer was because of an overloaded circuit that caused a fuse to blow.

- Why is the circuit overloaded? The answer was that there wasn’t enough lubrication on the bearings, which caused them to lock up.

- Why was there insufficient lubrication on the bearings? The answer was that the robot’s oil pump wasn’t circulating enough oil.

- Why is the pump not circulating sufficient oil? The answer was because metal shavings clogged the pump intake.

- Why is the intake clogged with metal shavings? The answer was the the pump didn’t have a filter.

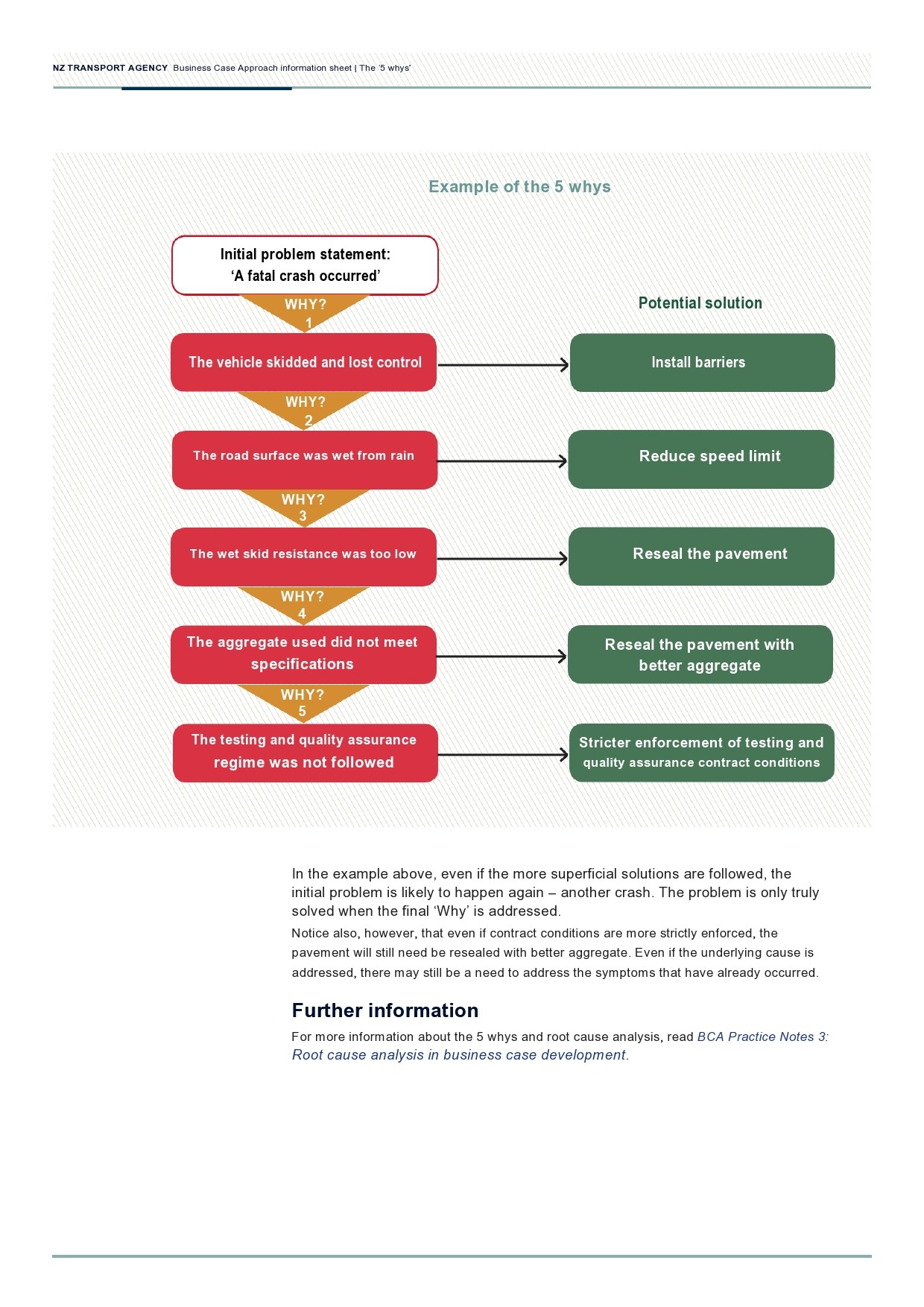

If the questioning stopped after the 1st or 2nd “why,” do you think you would have reached the same conclusion? Maybe, but the issue could have happened again after some time. In this example, the issue happened because of human error as someone forgot to attach a filter to the pump. Asking “why” several times and getting answers will help you arrive at the core issue, which is usually challenging to uncover.

What is the purpose of the 5 Whys technique?

You may have already experienced issues that persistently don’t go away. When you have such recurring or stubborn issues, they indicate a deeper issue. While “quick fixes” seem more convenient, they only solve only the issues on the surface. You might end up wasting resources that you could have used to deal with the true cause properly. Even if the 5 whys technique and using a 5 whys worksheet are very simple, they are both effective and powerful tools that you can use to quickly cut through to the root of a problem and find underlying causes for you to deal with once and for all.

You can use this technique in different ways like quality improvement, problem-solving, and troubleshooting. But it’s most effective for solving moderately difficult or very simple issues. But this might not be as effective for handling critical or complex issues. The reason for this is that the 5 whys might lead you to follow just one or few tracks of inquiry when there might be many causes. For complex issues, it’s recommended to use a wider-ranging method.

Though simple, the 5 whys technique is very effective as it will quickly direct you to the problem’s root cause. Whenever a process or system isn’t working well, try this technique first before embarking on an in-depth approach or before you try developing a solution. The technique’s simplicity also provides great flexibility as you can use it in combination with other techniques and methods.

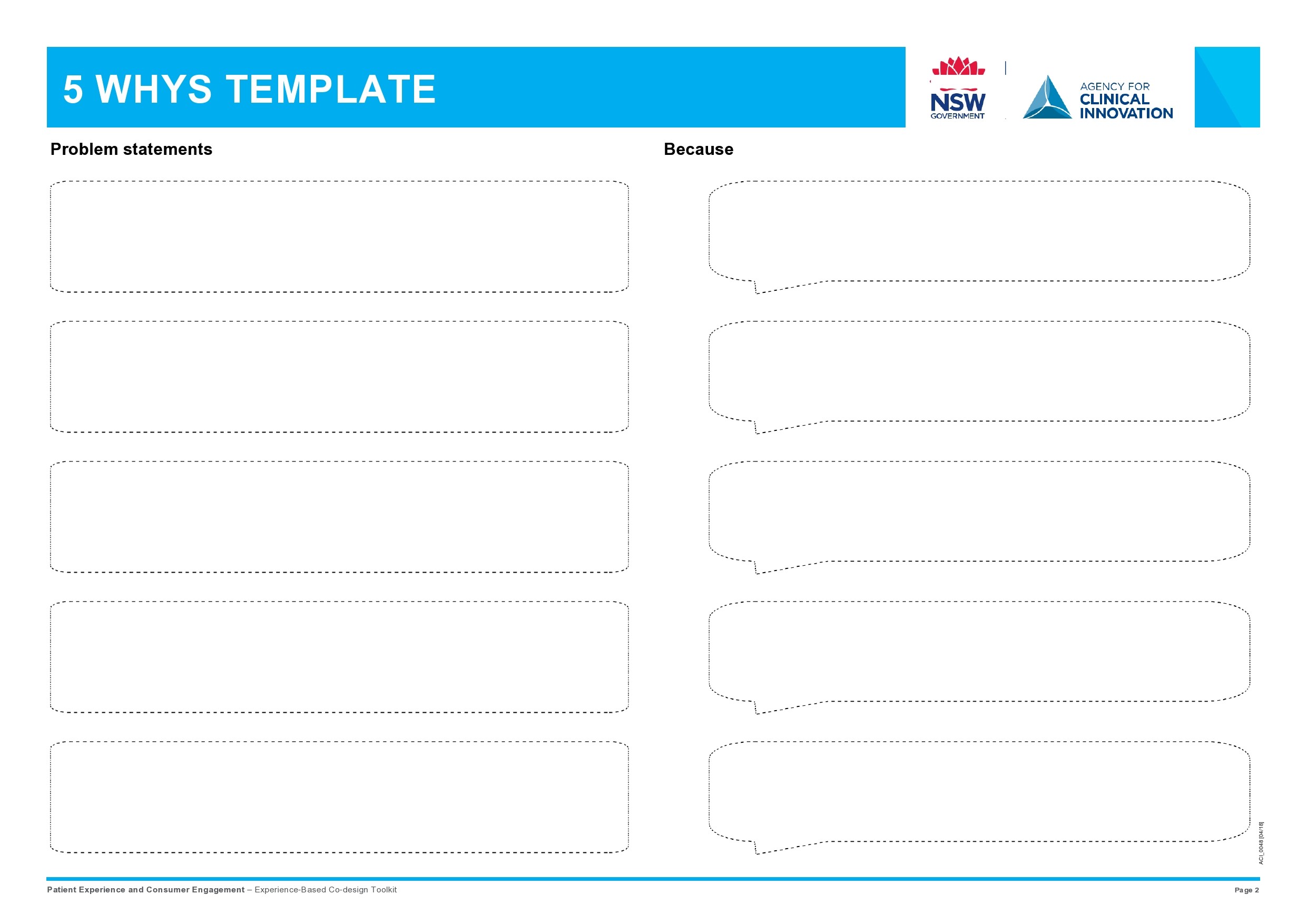

Using the technique in customer feedback teams

You can use this technique in different ways, even in the customer feedback process. In such a case, you can use it during your regular meetings where you will apply it to really bad feedback. For this instance, you can follow these steps:

- Set a schedule for your meetings where you would try to understand bad customer feedback.

- During your meetings, have these comments ready for quick reference.

- Frame each of the comments as a problem statement. If the comment has several ideas, you can break them down into different problem statements. Make sure that you will deal with one idea, problem, or thought at a time.

- Have your team start the 5 whys process on the first issue. Try to get the answers you need in 10 or 15 minutes.

- Finally, assign someone to validate the analysis that you have performed and search for a solution They can do this during the time between the current meeting and the next one.

The goal you’re trying to accomplish is to make the necessary changes to solve the problem quickly. ideally, you should the problem in 1 or 2 weeks. If you have reached the root cause but you still can’t resolve the issue fast enough, you should delegate a specific team to handle it. Another objective of this process is to make small changes that will make more significant changes in the future. If you can solve the problem, you can make your customers feel happy instead of just ignoring the issue altogether.

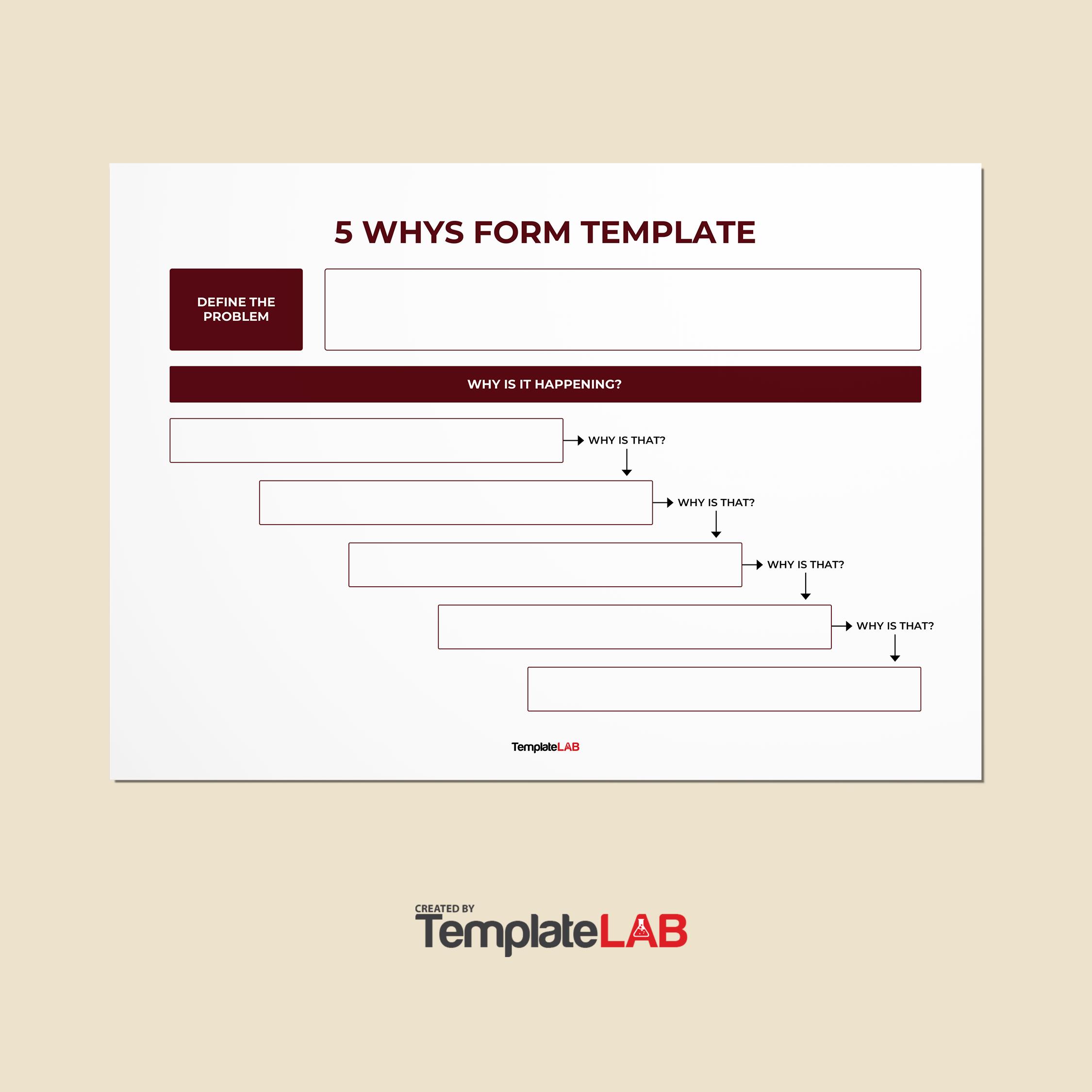

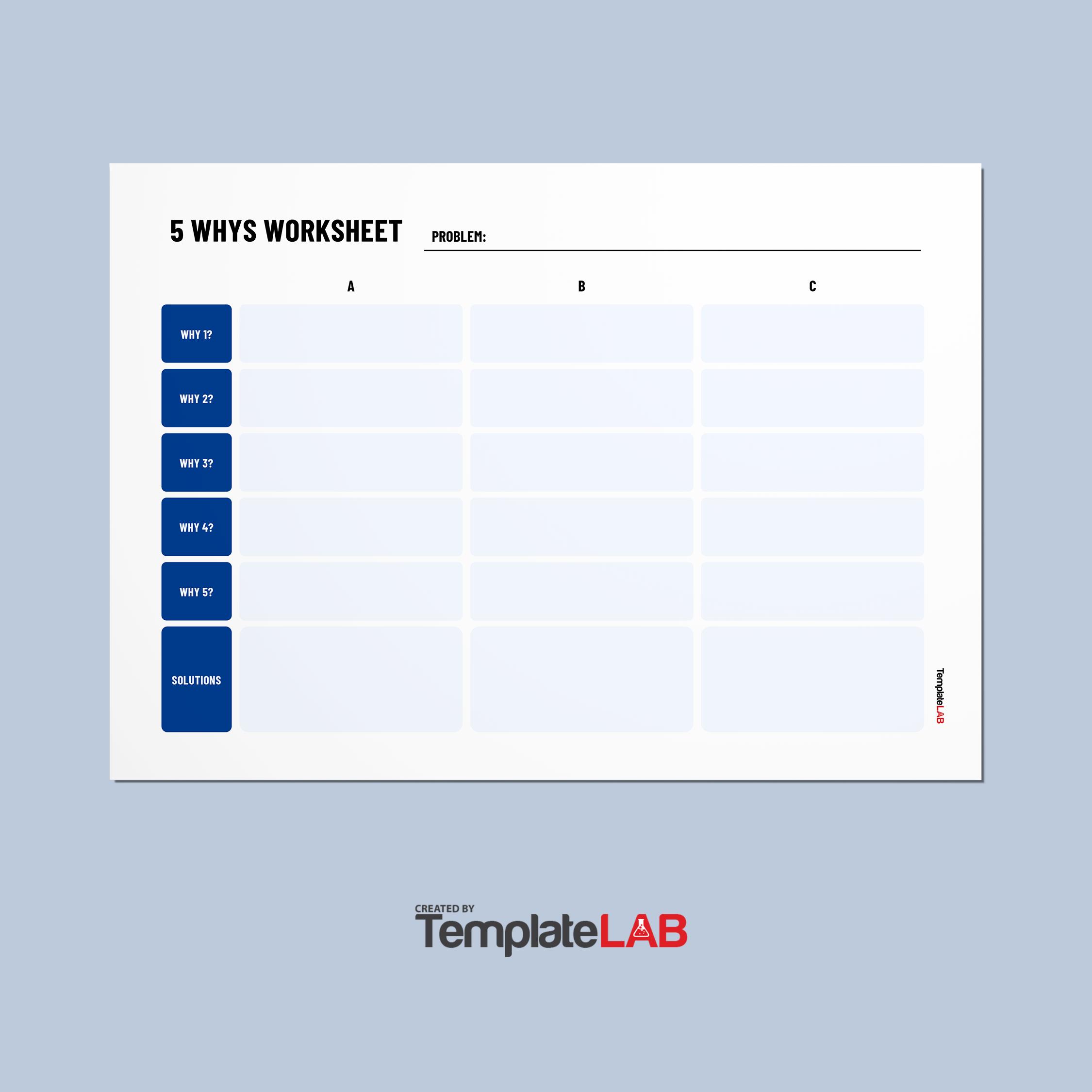

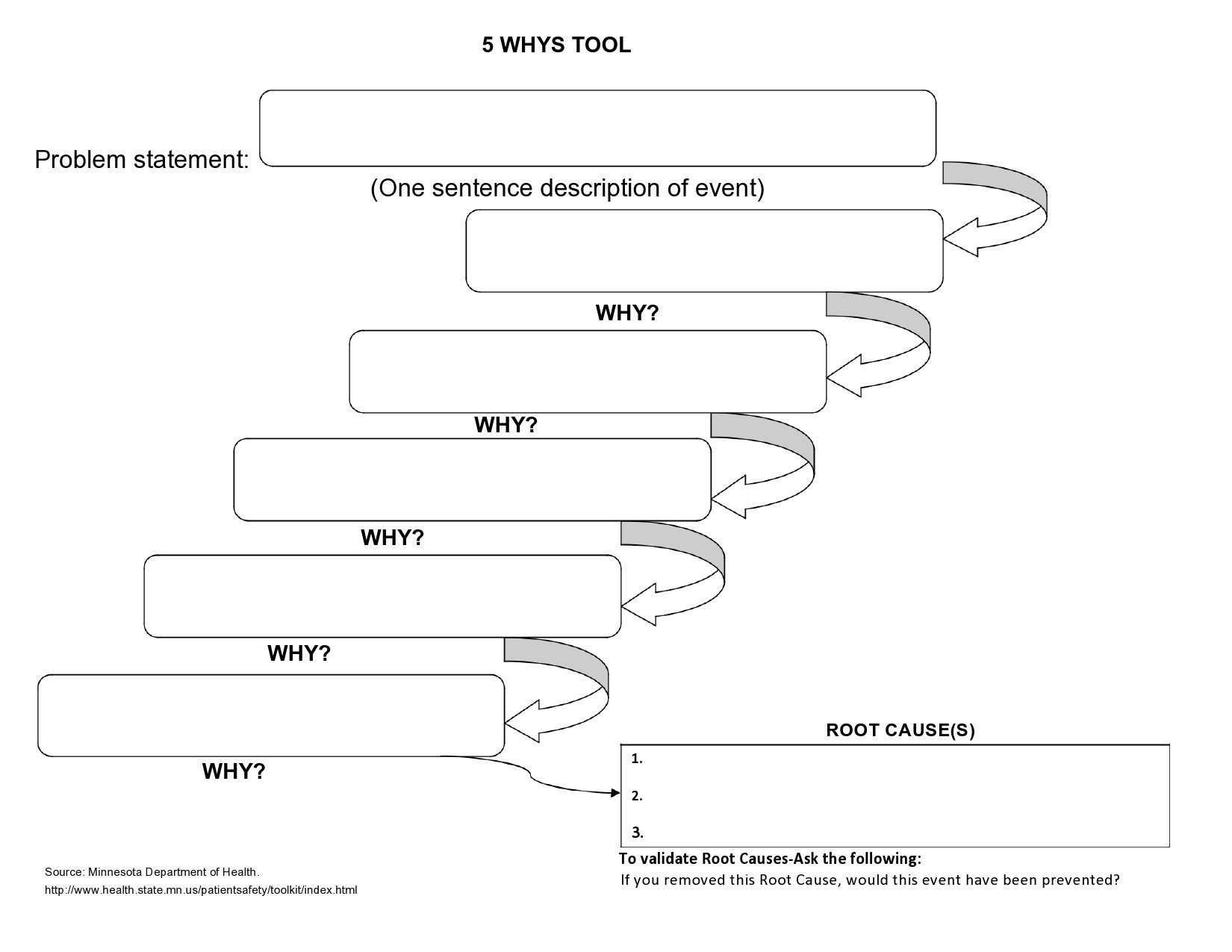

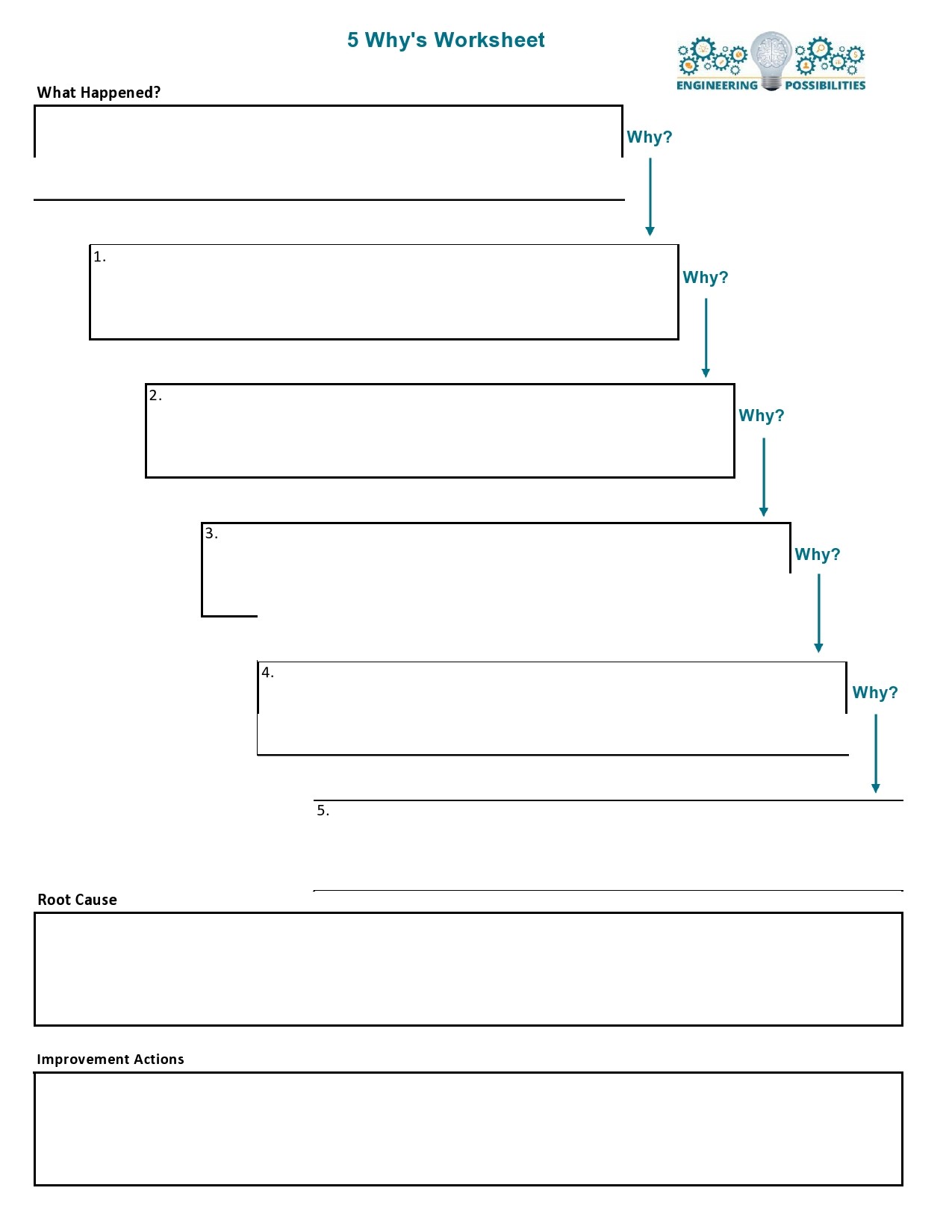

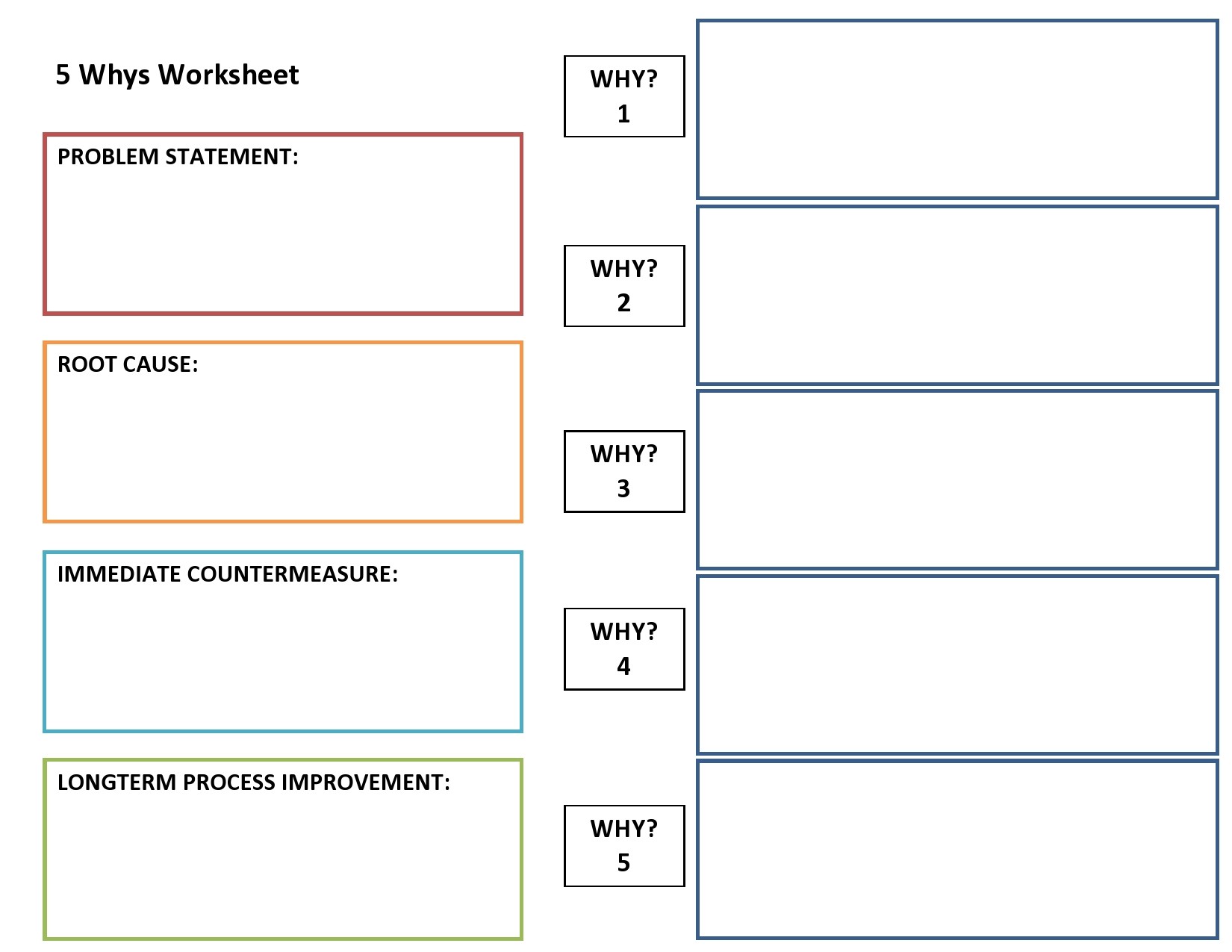

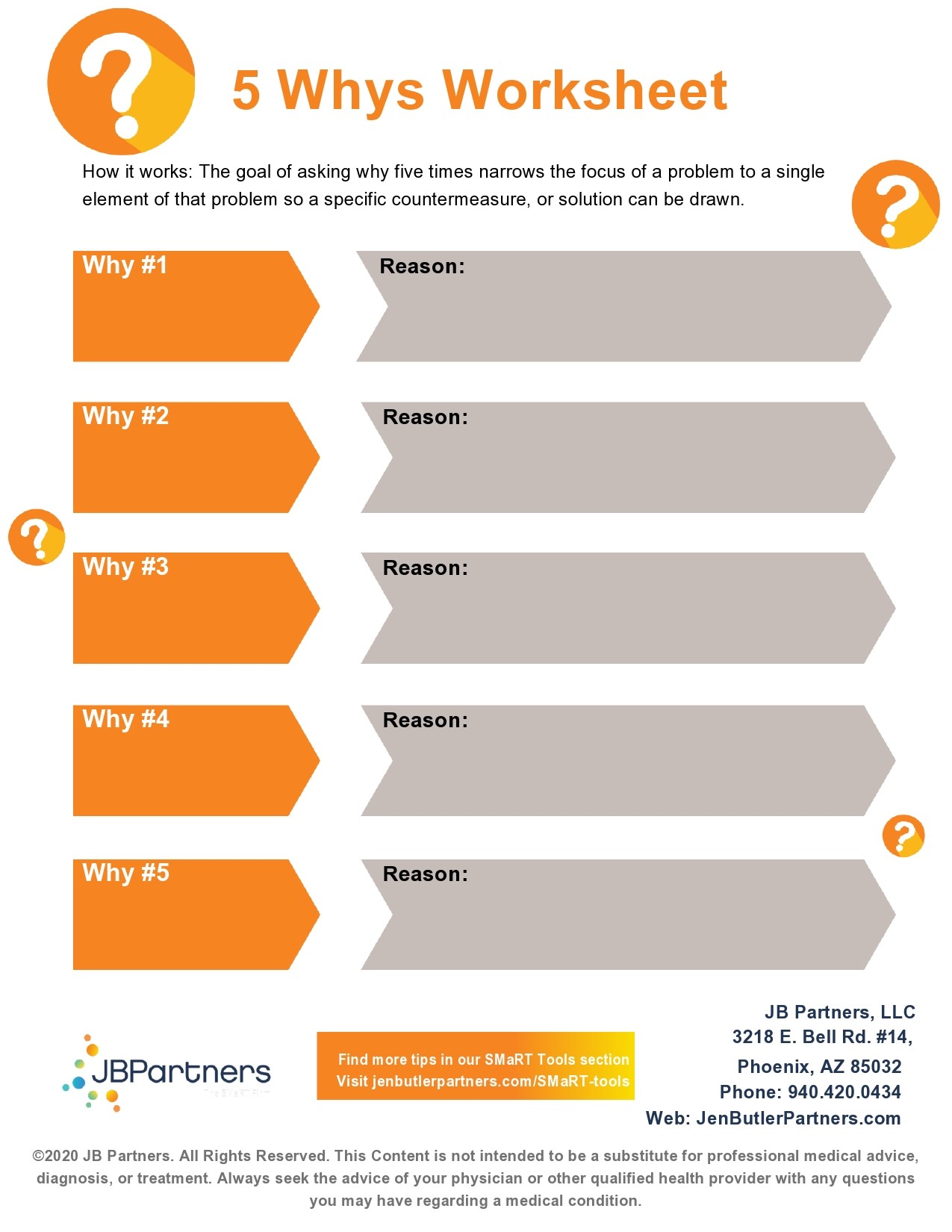

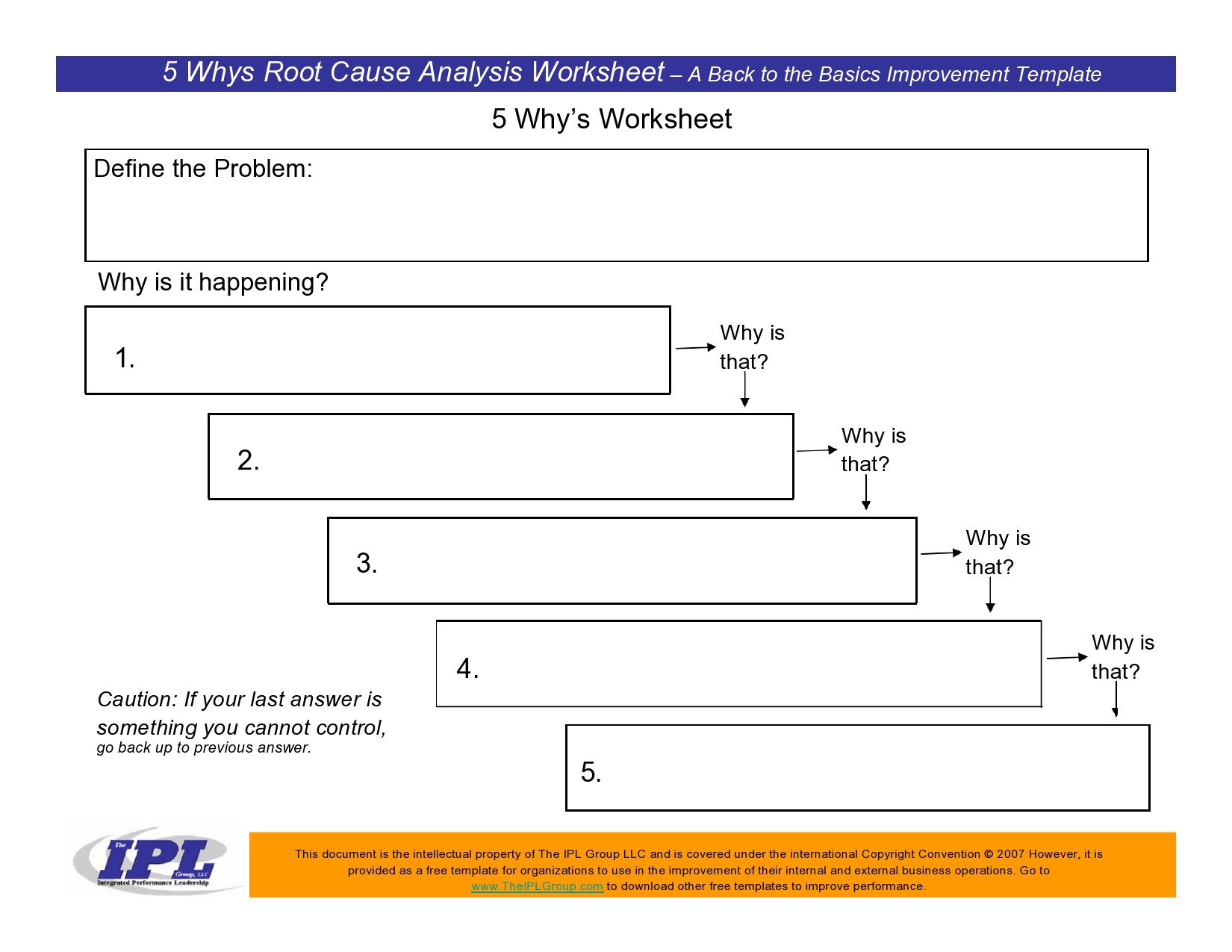

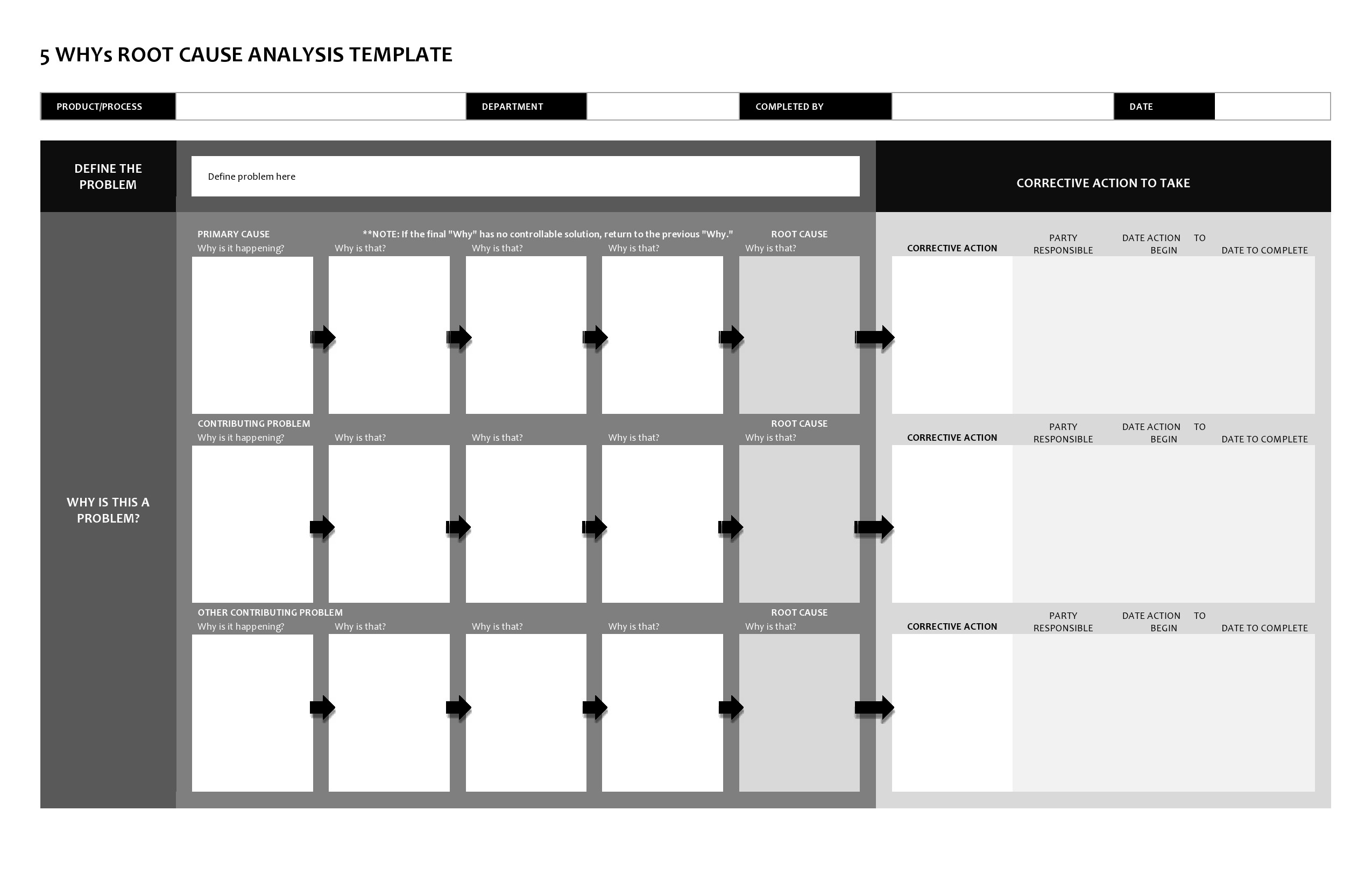

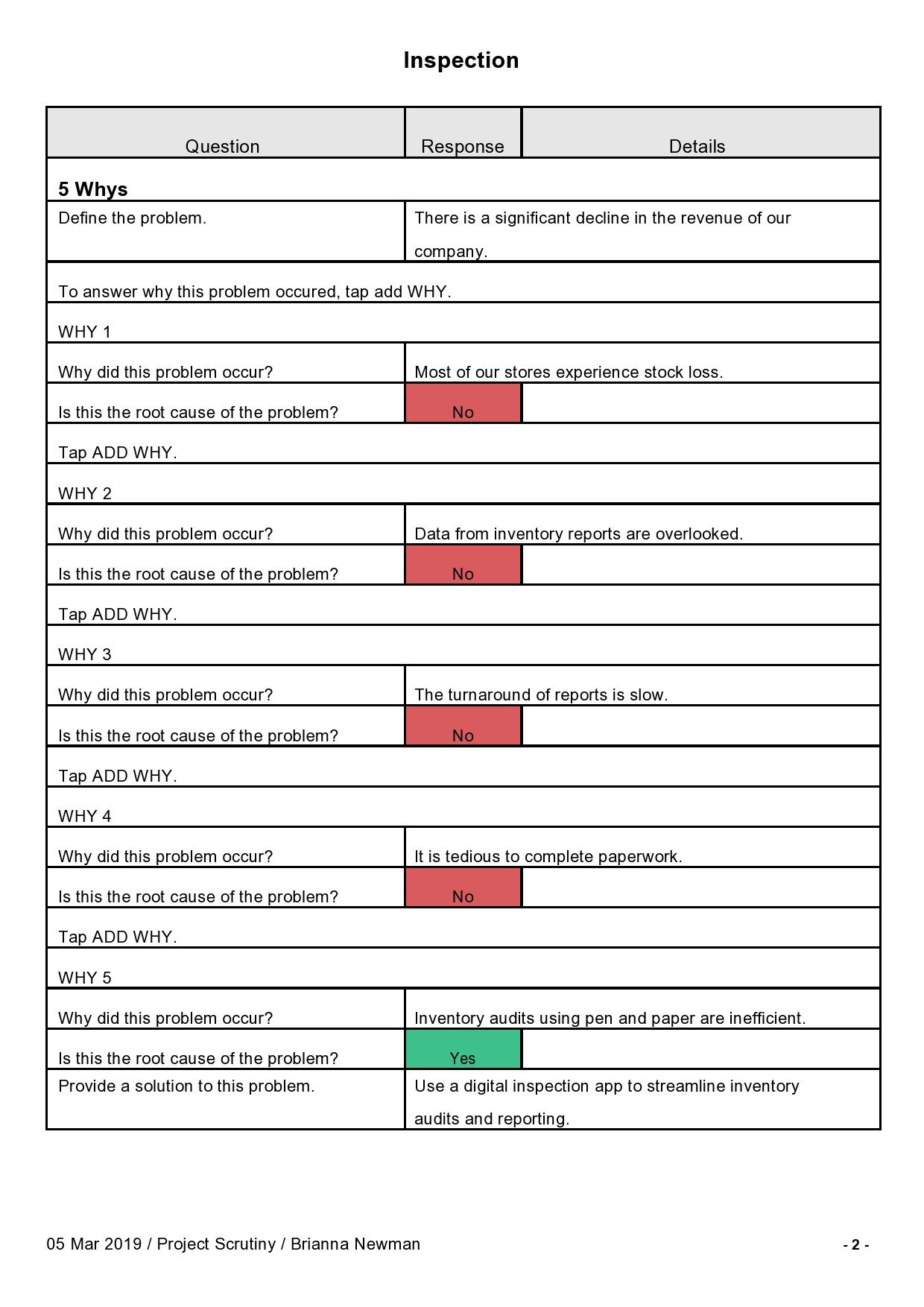

5 Whys Worksheets

Does it have any limitations?

The 5 whys technique is most effective when you apply it to solve moderately challenging or simple issues. If you will use this technique on more complex problems, you need to be very careful because complex problems usually have several causes. Using this technique can lead you to just one or few solutions, causing you to ignore the real issue. Since this technique is relatively easy, it’s the ideal tool for initiating brainstorming sessions around an issue before you take a more in-depth approach. Even so, this technique has a few limitations:

- The person who will lead this process must be an expert on the issue. This approach might not lead to the true cause of the issue if you have no idea of the possible cause either.

- The success of this technique depends on your skill as the team leader or facilitator. One wrong answer could throw the questioning off completely, which will ultimately lead to an inaccurate conclusion.

- One characteristic of this method is the assumption that all symptoms come from a single cause. But for complex issues, this isn’t always the case, which means that this method might not uncover all of the causes of the issue.

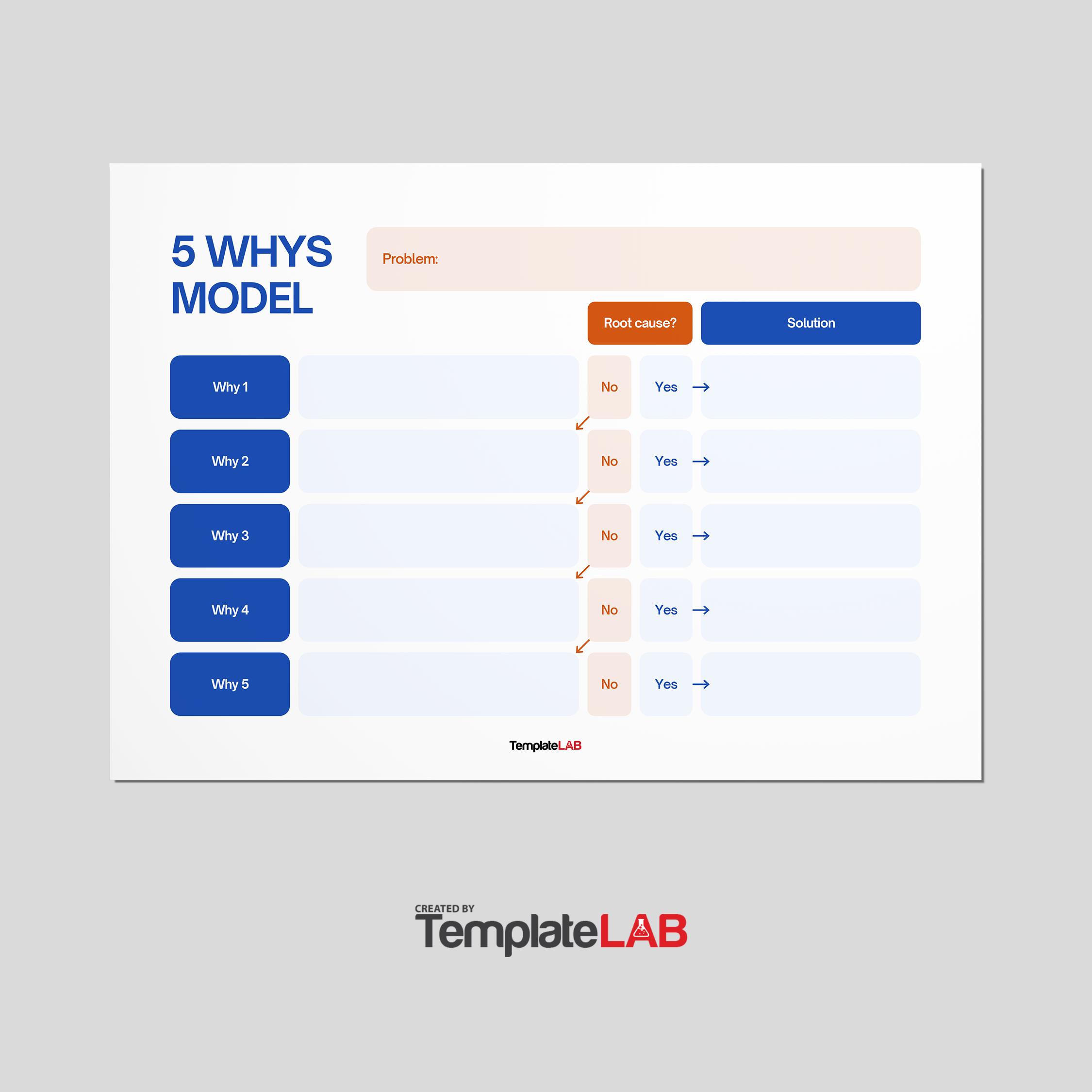

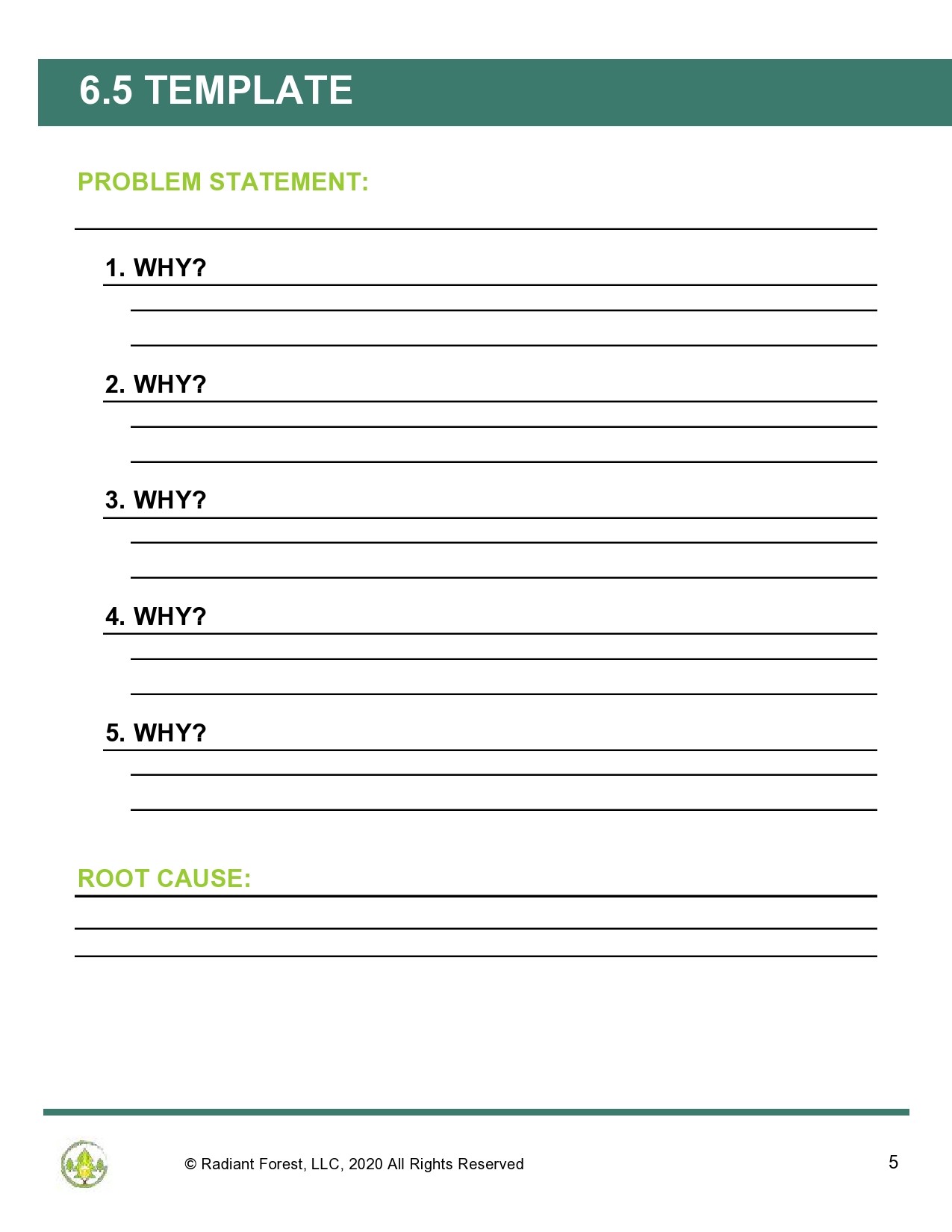

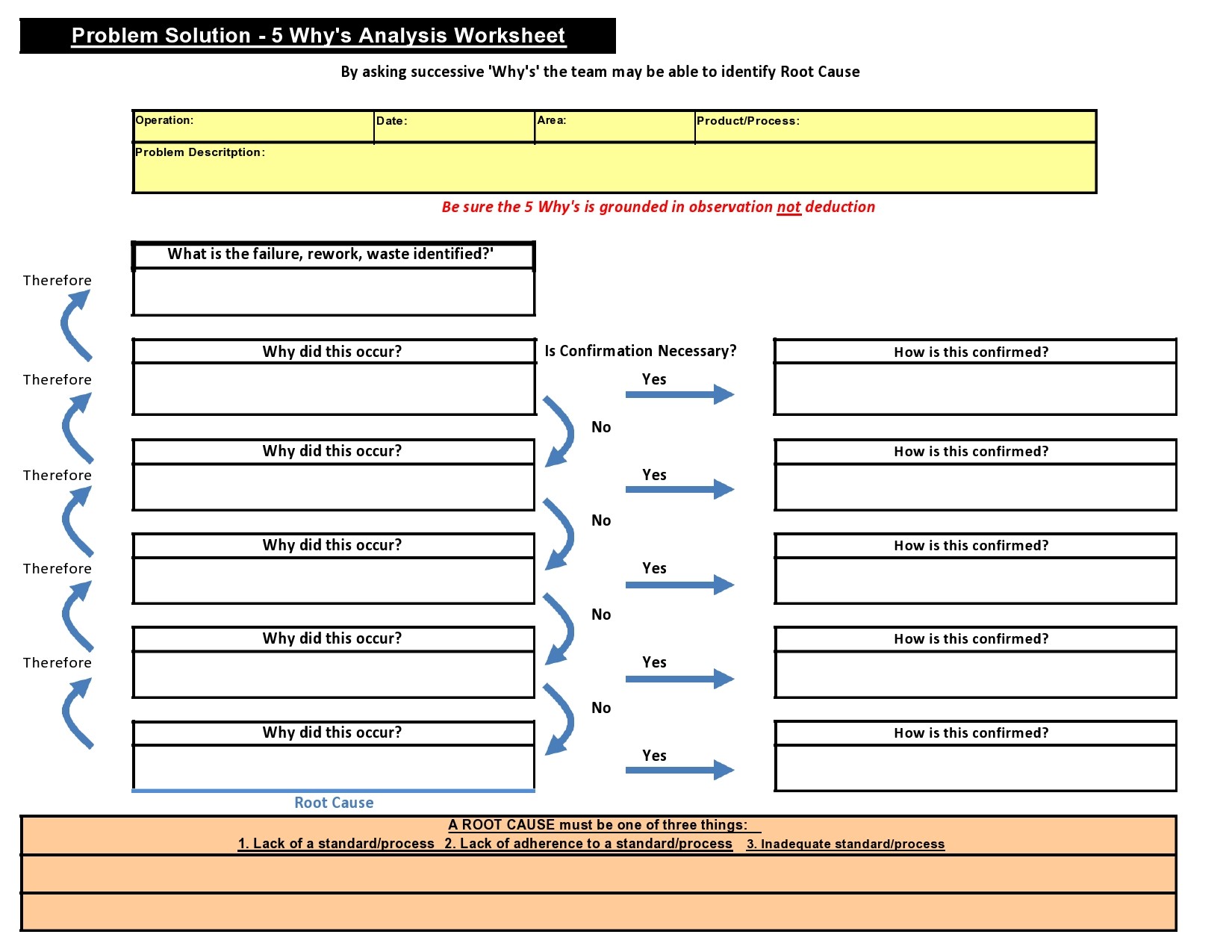

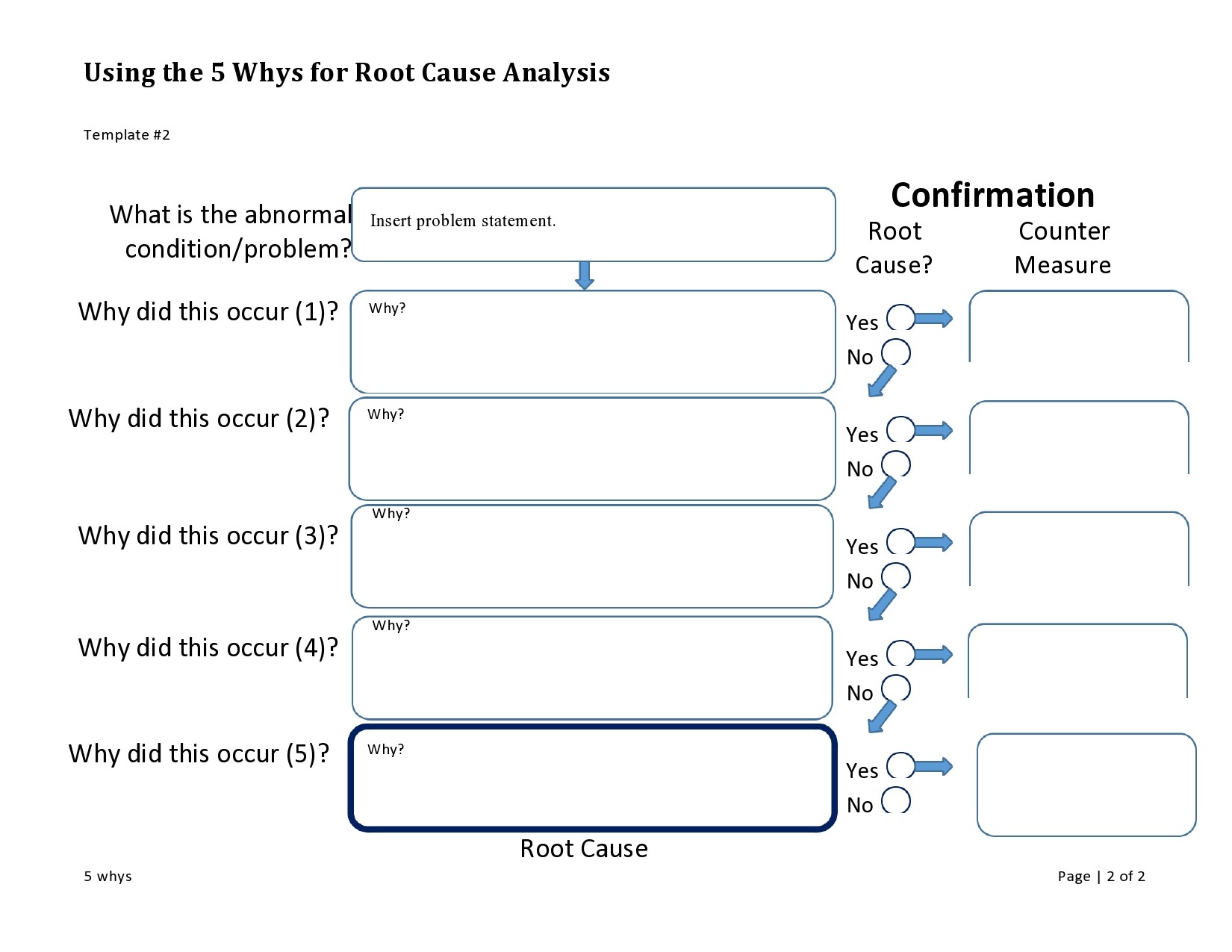

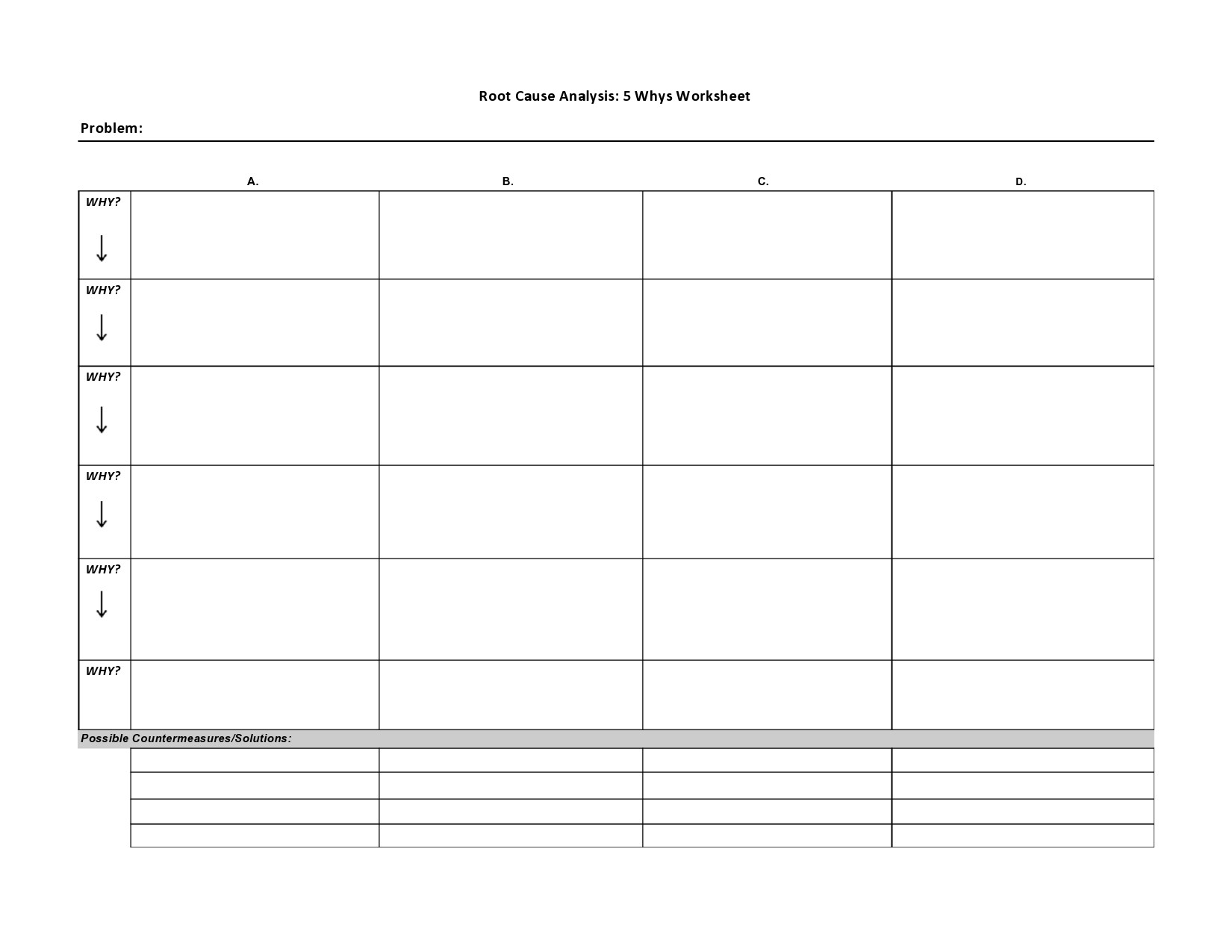

How do you document 5 Whys?

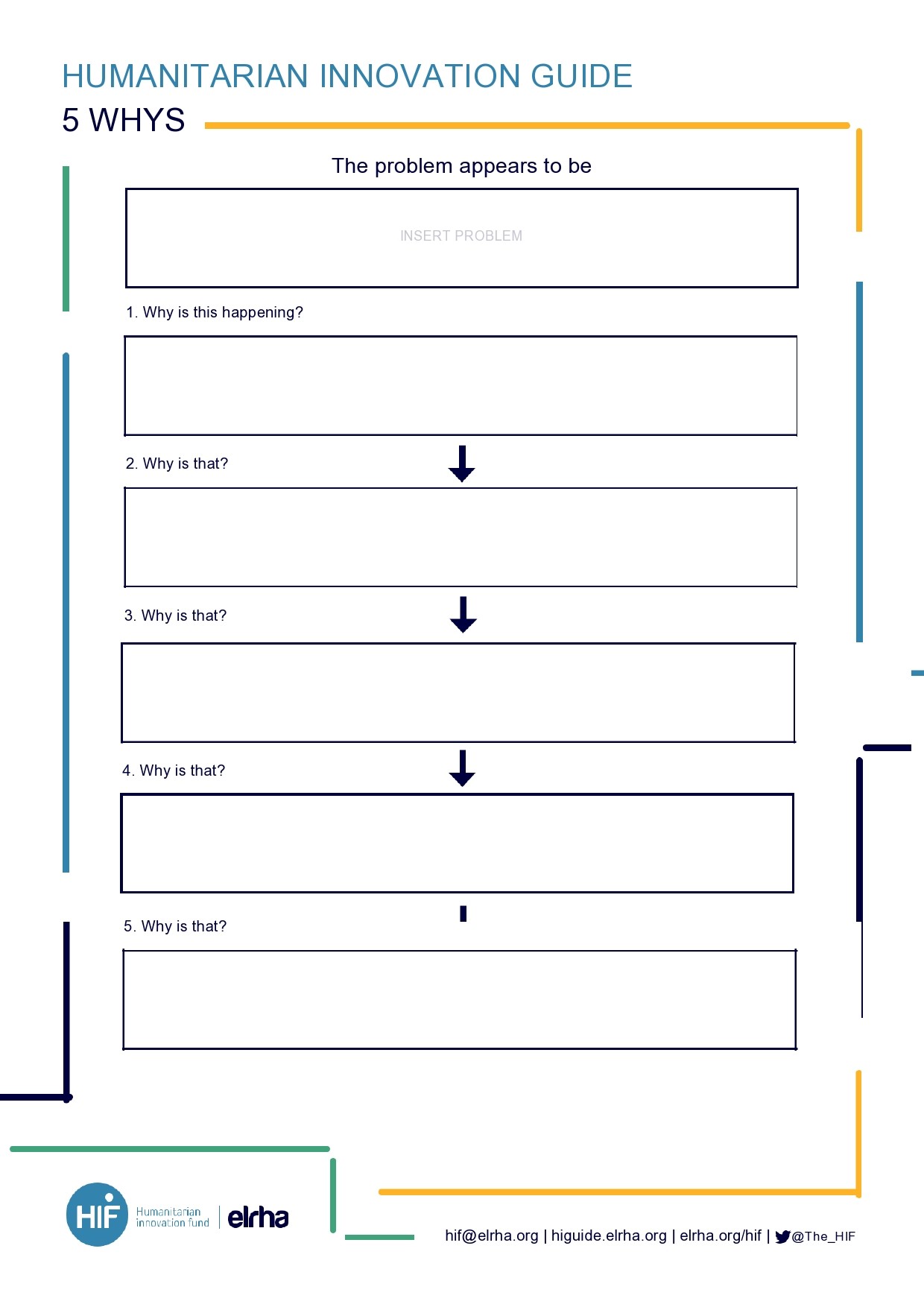

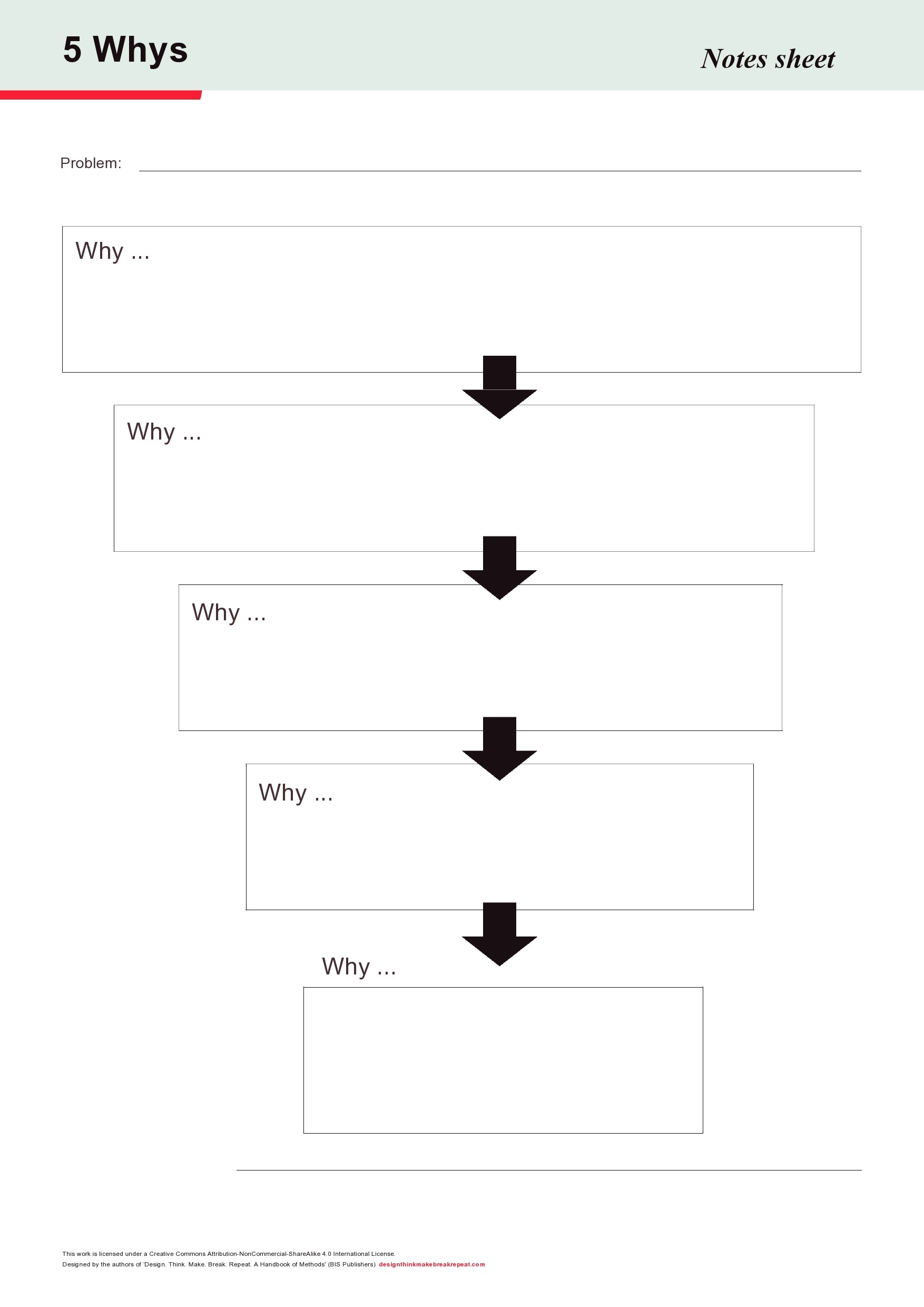

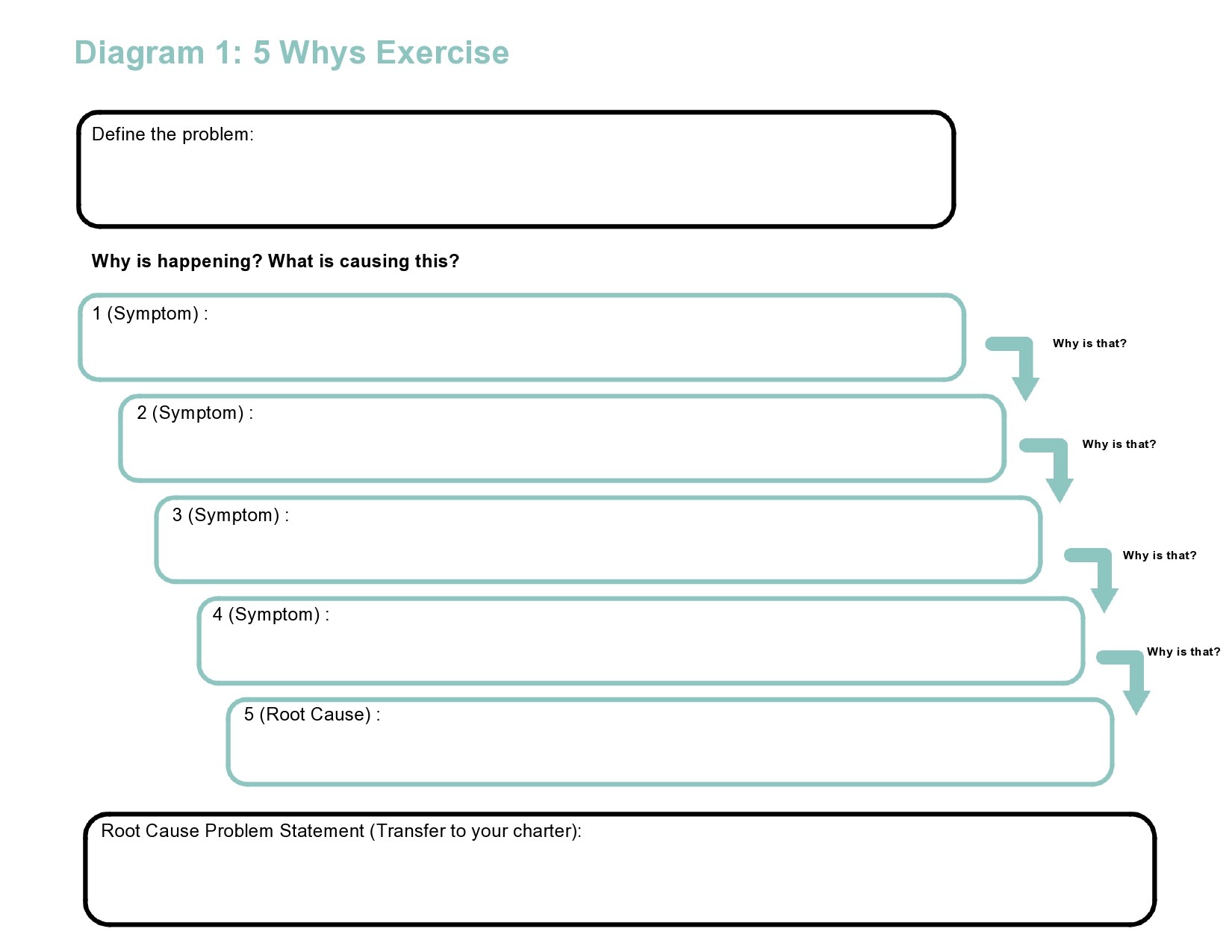

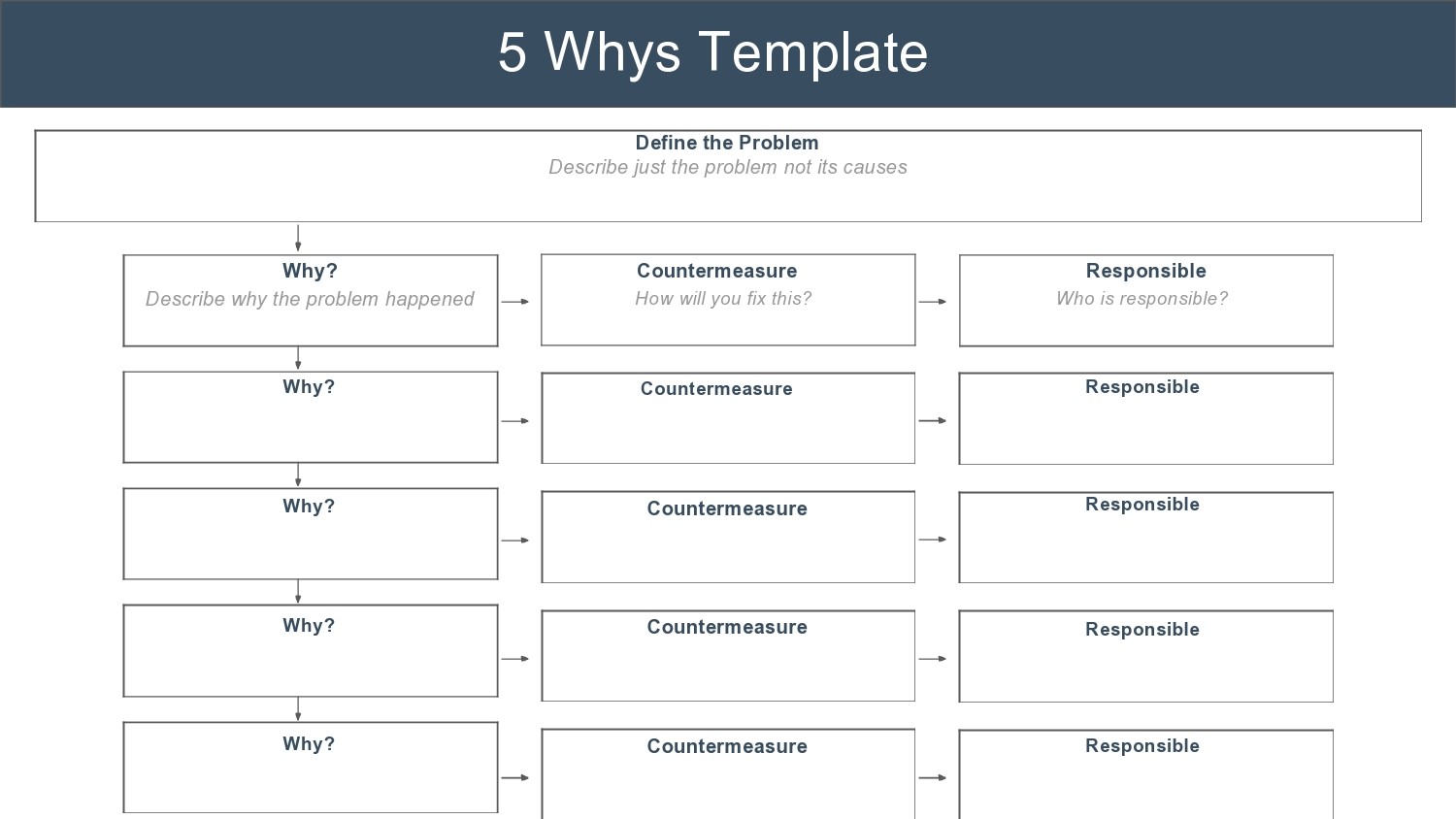

Effective and simple as this process might be, it might not produce the desired effects if you overlook the baseline principles. Even if you use a 5 whys diagram, you still won’t solve the issue. To ensure that you do this properly, here are the steps to follow when documenting the technique:

- Define the issue clearly

One of the main reasons why people have difficulties determining the root cause is that they don’t have a clearly defined problem. If you’re leading the team that performs the process, you should assist them in establishing the main issue based on existing knowledge. You should also remind your team members to avoid jumping to conclusions or blaming people for the issue. Spend some getting a good grip on the issue. Don’t skip this step as it might prevent you from getting to a clear solution.

- Check if the answer is the root cause

After asking the first question, determine if the answer is the true and underlying root cause. If the answer is “no,” you need to keep asking questions. Do this until you obtain the root cause of the issue. You can ask this “why” question up to five times until you get to the main underlying cause. But there may be times when you will need less than or more than five questions. So it’s recommended to keep going until you find the solution you’re looking for.

- Know when it’s time to stop

The participants of the process should pay close attention to the logic behind the cause-and-effect relationship. If your team members aren’t paying attention, chances are, you will have to keep going back to the issue and you won’t reach a solution in a timely manner. This is another task that you as the team manager should teach. You should train your team members on how to differentiate causes from symptoms. A useful tip to share is when the answers start becoming illogical, you shouldn’t continue anymore.

- Delegate responsibilities to the members of your team

The members of your team may face the same issue if they don’t follow through on the effectiveness of the solutions you have thought of. So you should monitor the implementation of the solutions you came up with by delegating the responsibilities to your team members. When all of your team members take action, the whole team will create an atmosphere of trust while increasing accountability.

- Solve the issue

After arriving at the root cause of the issue, you must fix both the root cause you have discovered and the symptoms. The main objective of fixing the issue is to prevent it from happening again. This is also the main reason why you would perform the method. You should also deal with the symptom that initiated the issue in the first place. Remember that if you perform the process correctly, it will be the last time you need to fix it.

- Follow up by monitoring your solution

You should keep a close watch on the effectiveness of the countermeasures that you have used to minimize or eliminate the issue. There might be a need to fix your countermeasures or replace them completely. If the issue occurs again, it’s recommended to repeat the process to ensure that you have identified the root cause correctly.

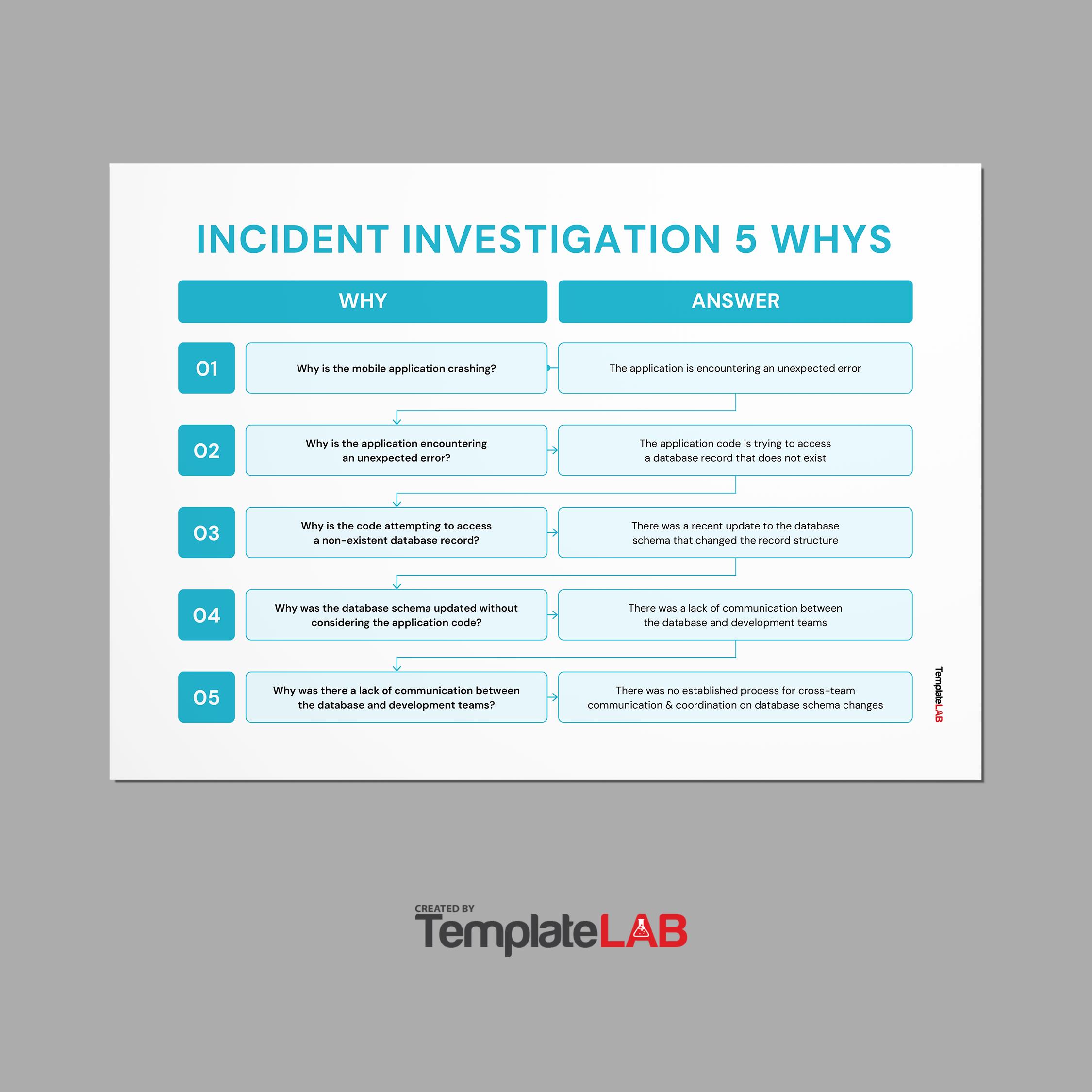

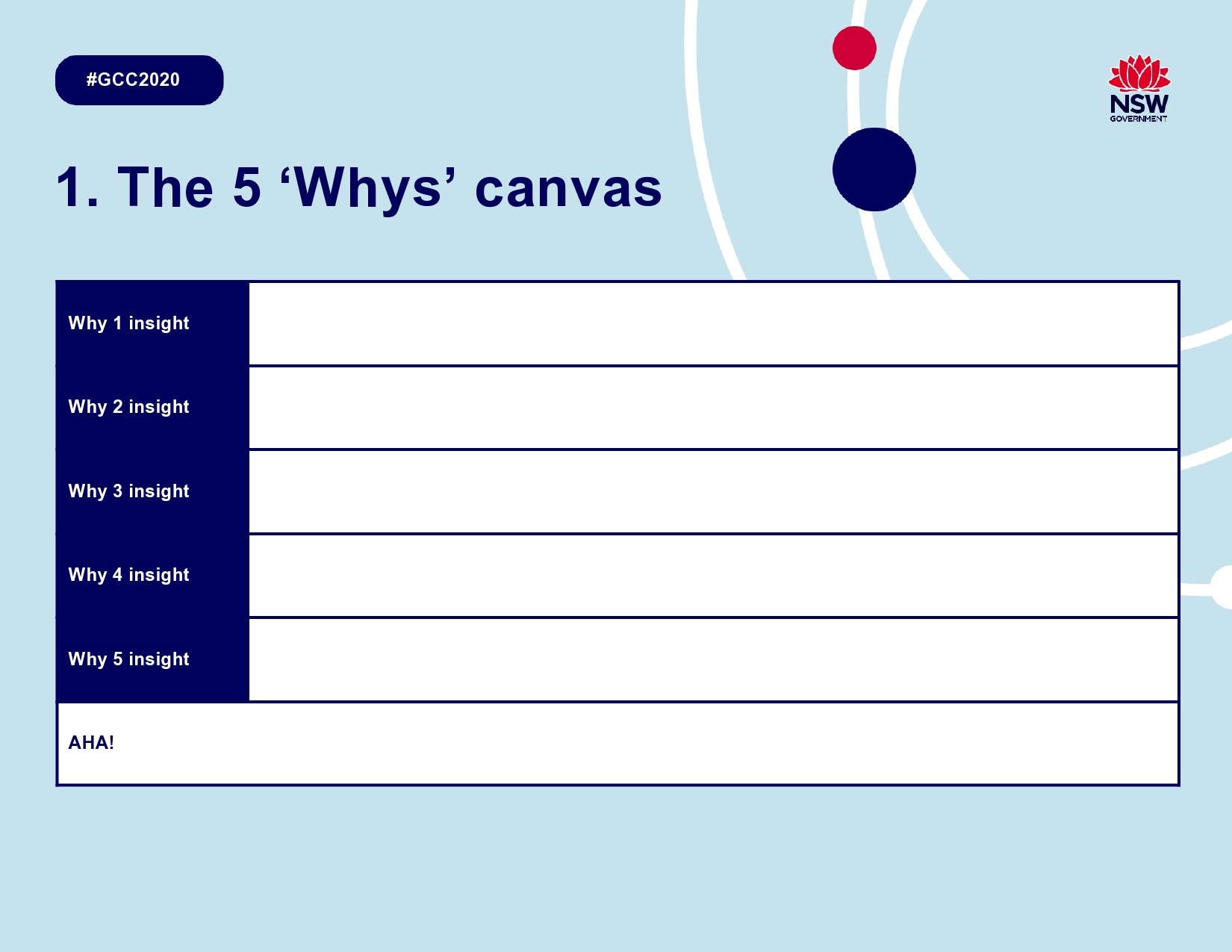

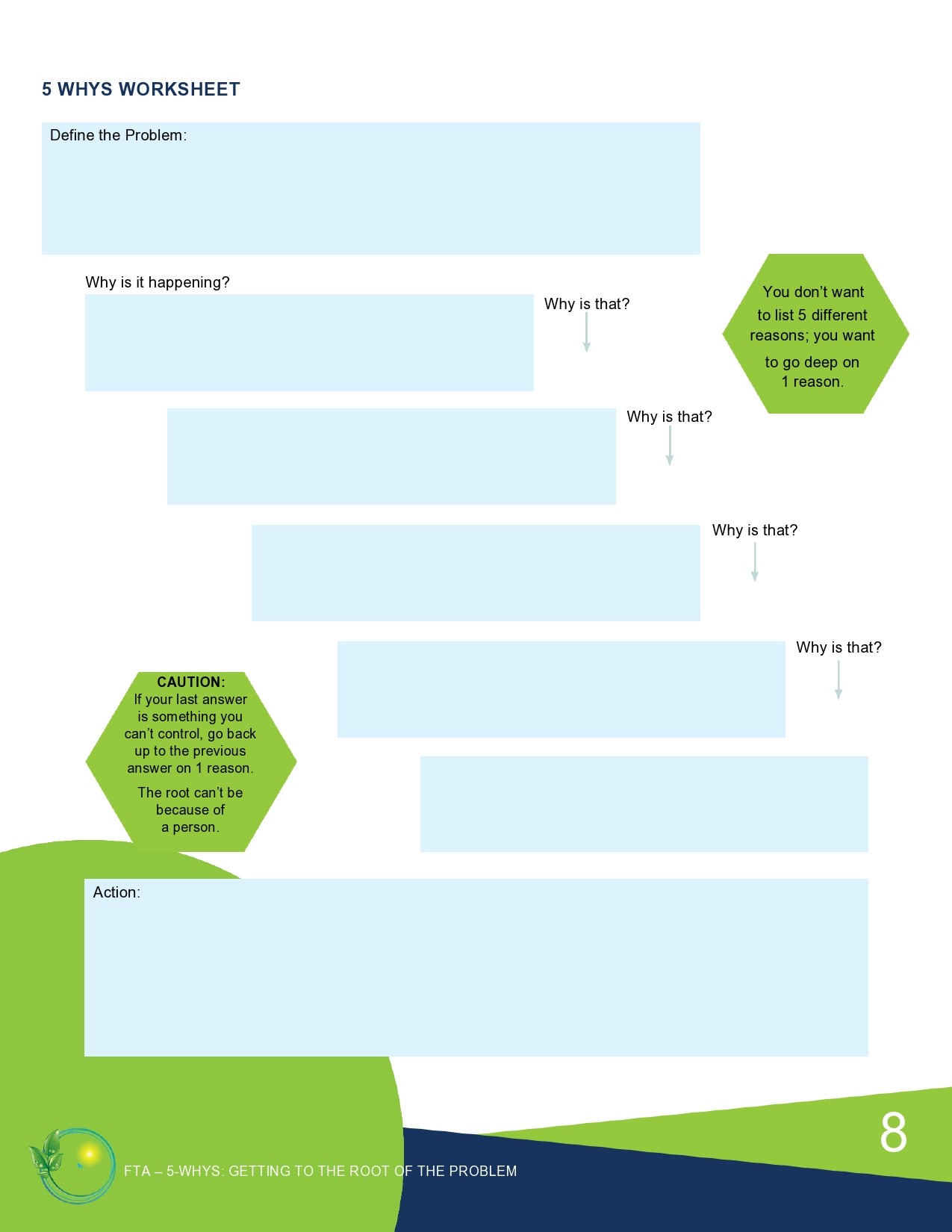

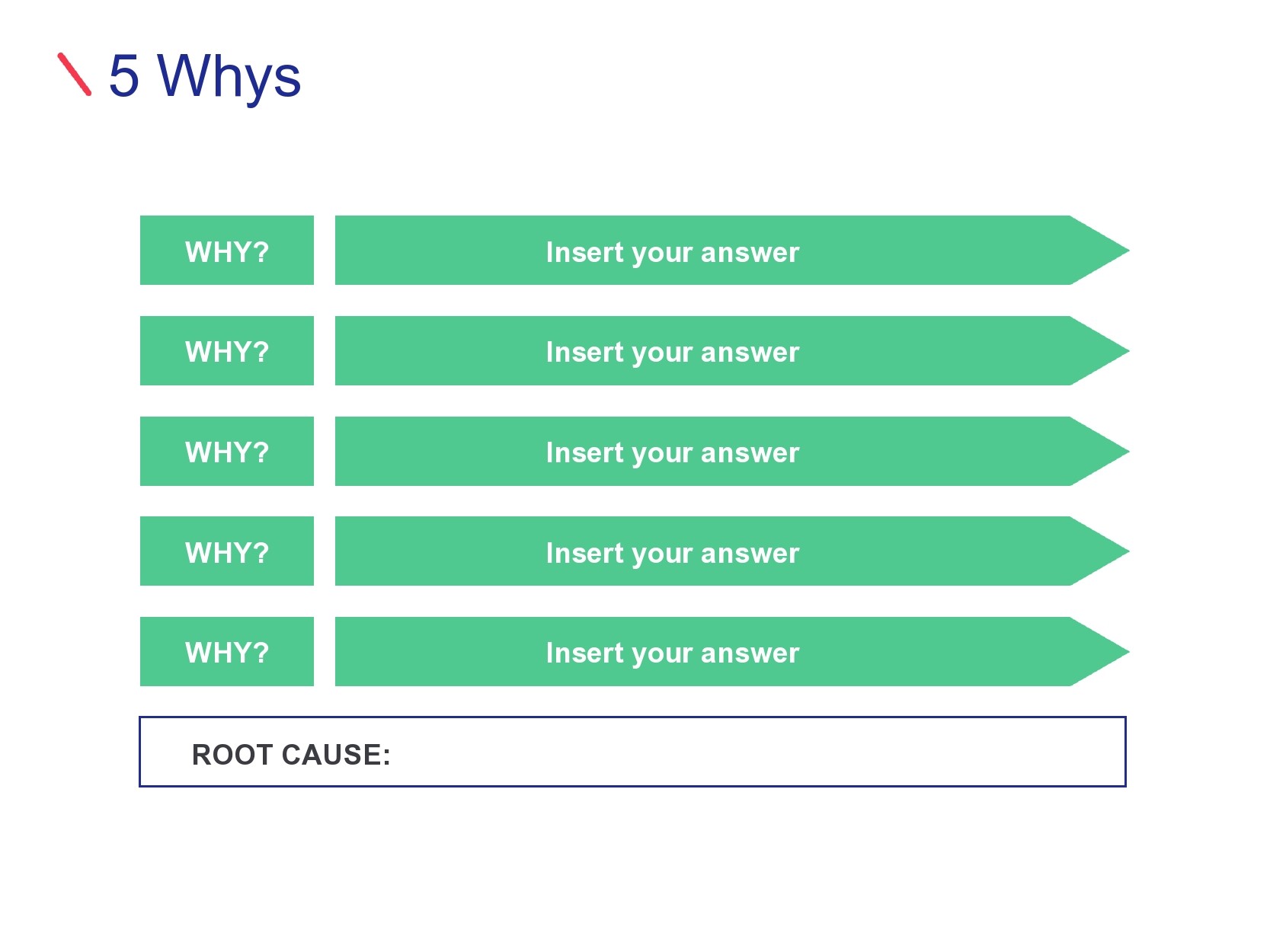

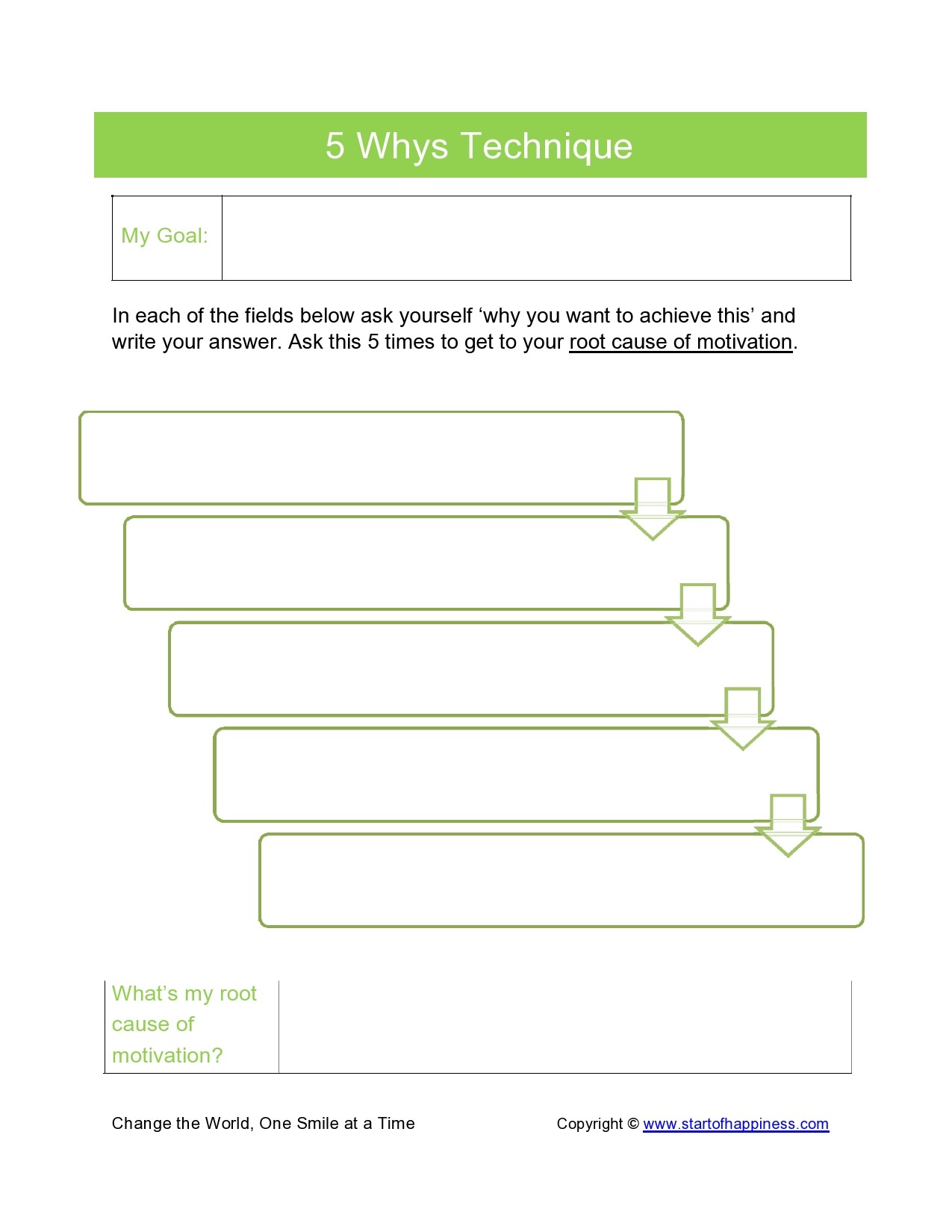

5 Whys Diagrams

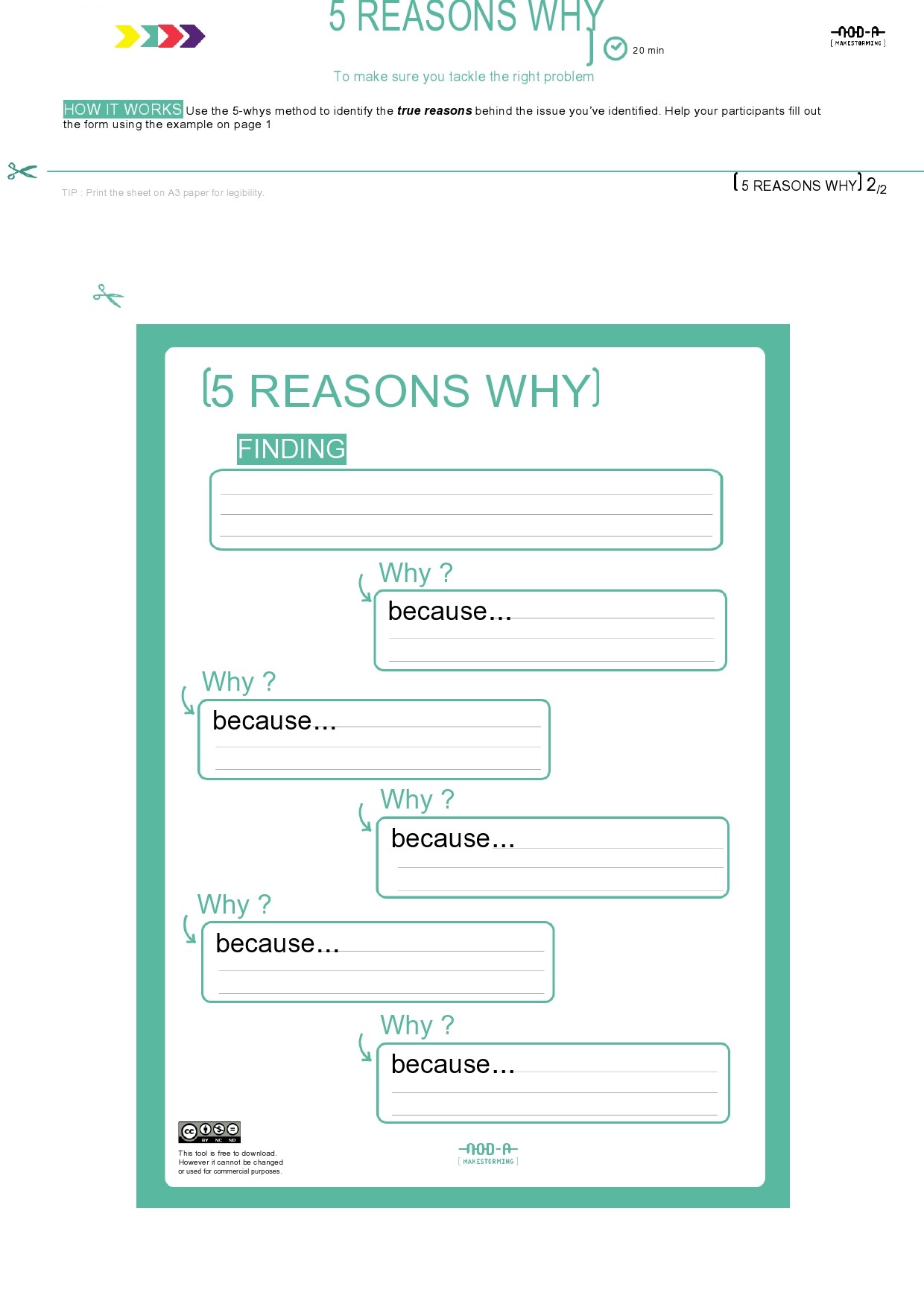

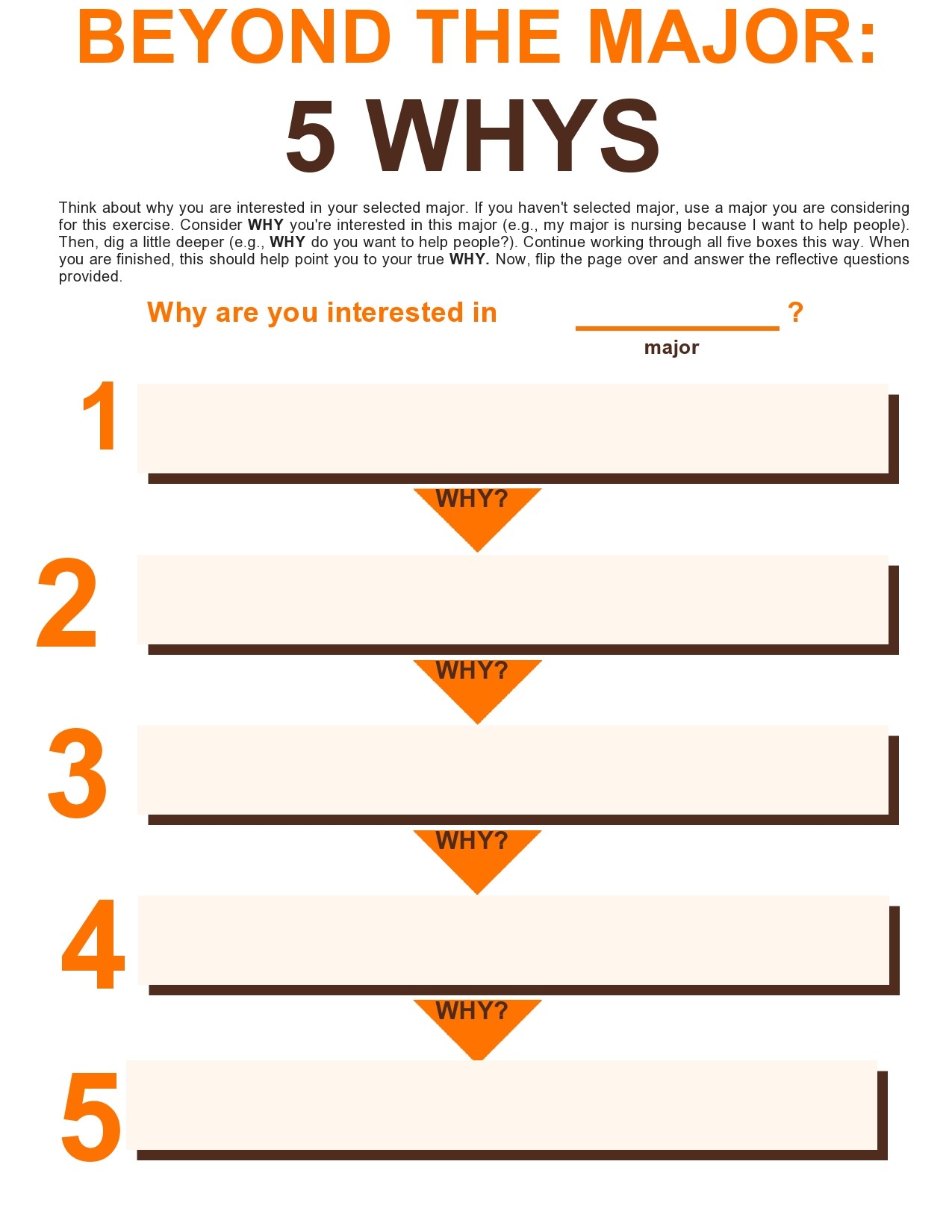

How to use the 5 whys template?

The 5 whys problem-solving technique was originally created for the production facility of Toyota Motor Corporation. The technique begins with one issue, then you ask a “why” question up to five times based on the answer you get from the last question. The repetitive process of asking questions will ensure that each step is logically connected to the next through a cause-and-effect relationship. Each “why” in the process takes you closer to uncovering the root cause of the issue.

This process is also a brainstorming session, which means that you can work through it using a whiteboard or sticky notes. Mapping the process out using these simple tools will help your team members visualize everything you discuss. You can also work on a template and write your ideas on sticky notes. Here are some steps to follow when performing this technique:

- Ask the right questions. Before you begin your 5 whys technique, you need to have the right question. Having a problem statement can help you with this.

- Present to the right people. All team members, stakeholders, and decision-makers must be part of the process. It’s to you choose a capable moderator to drive the discussion and ensure that each of the steps is accurately followed and that everyone avoids making assumptions.

- Share the template with everyone. While presenting, add sticky notes to write down the comments of your team members for each question. After completing the process, identify the action points, then print out your template so that you can use it as a reference. You can also print copies for your team members to keep them informed and updated.