Panel schedules that are updated and correct are essential for safety. In an emergency, they could save time and guarantee the safety of service personnel and contractors who are servicing or installing equipment. Proper schedules assist teammates in determining what equipment is powered by each breaker and provide a reference point for locking out and tagging out for safety. Appropriate labeling standards are as important, allowing you to identify apparatus that has to be de-powered even when there are several breakers controlling identical machinery and when there is personnel in the facility who are not familiar with the infrastructure.

Table of Contents

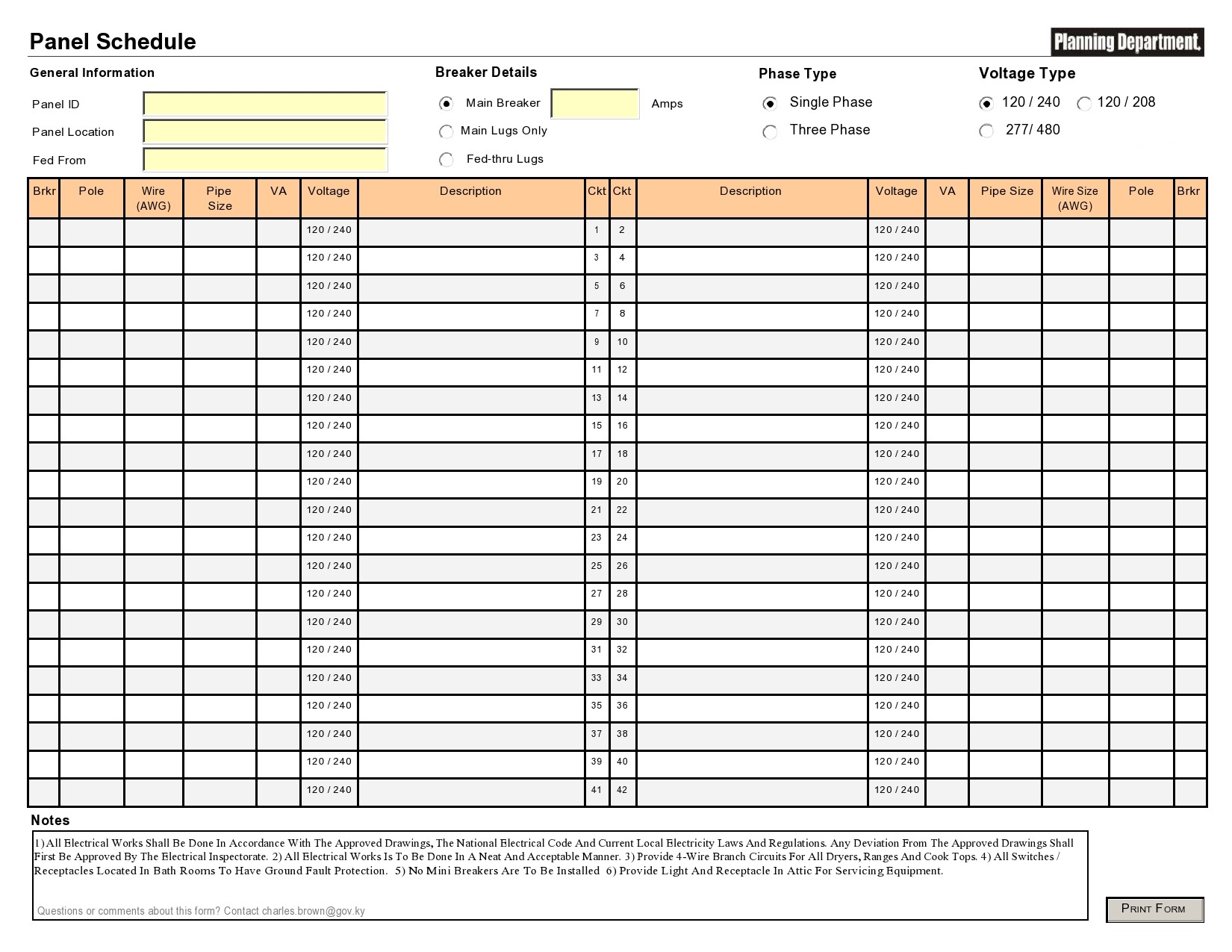

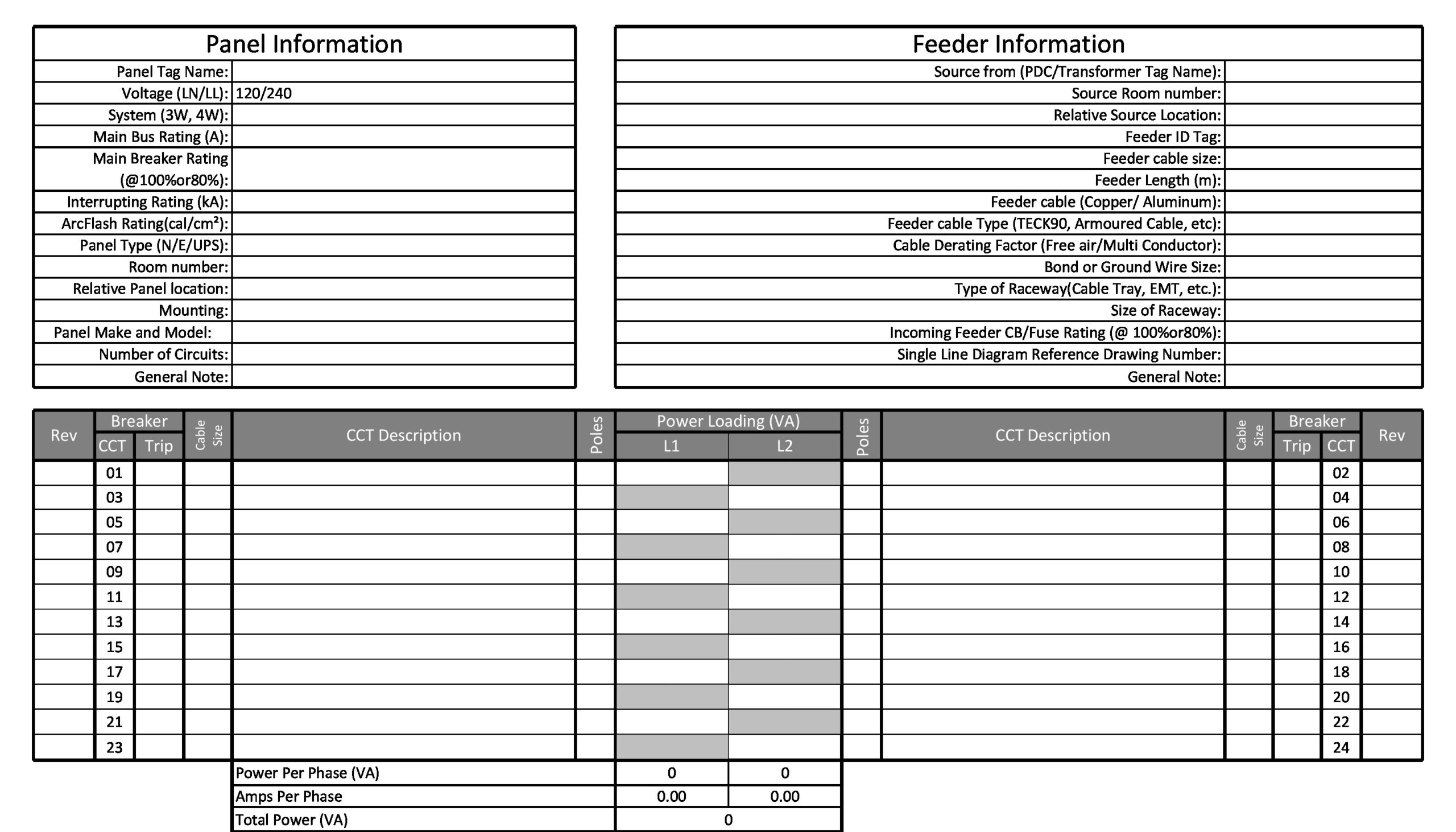

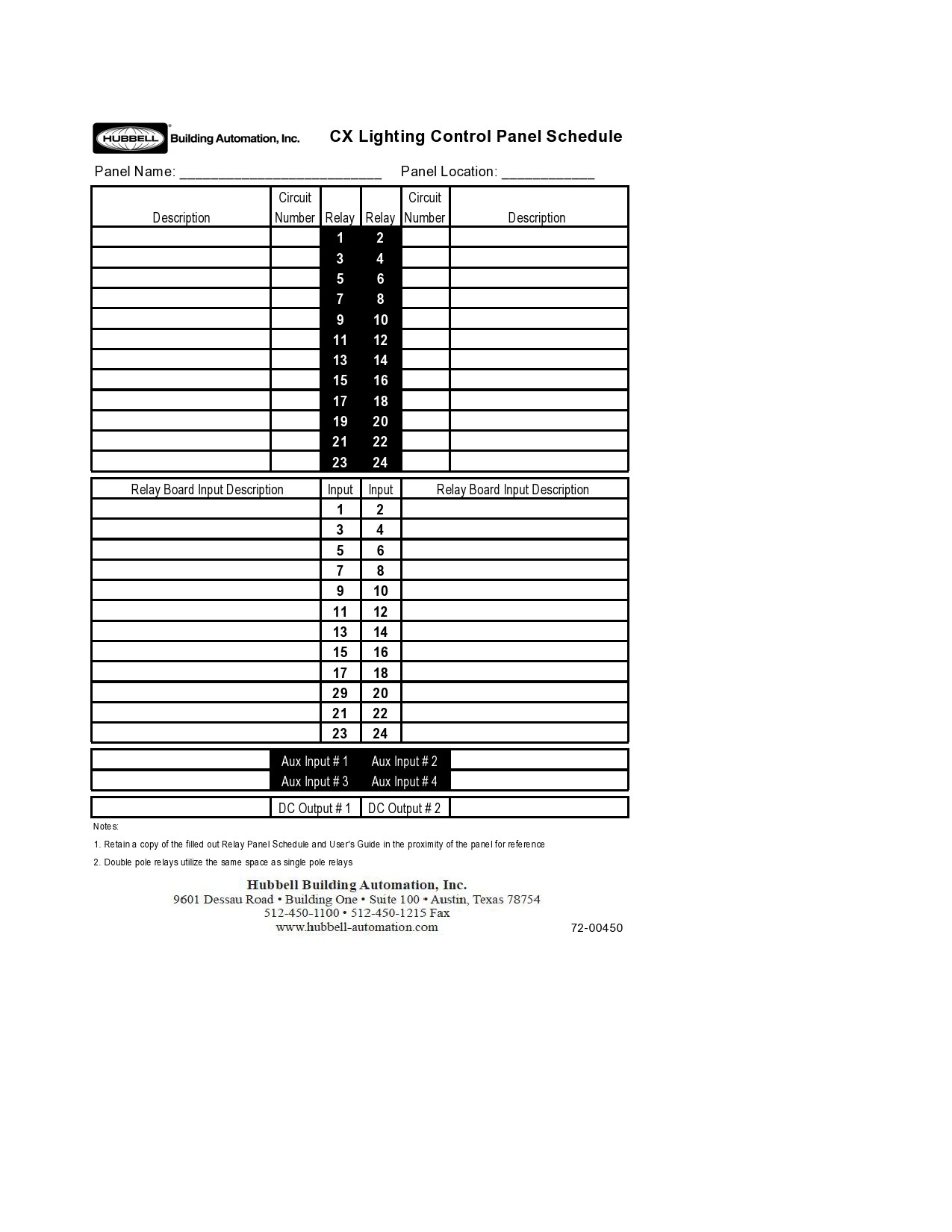

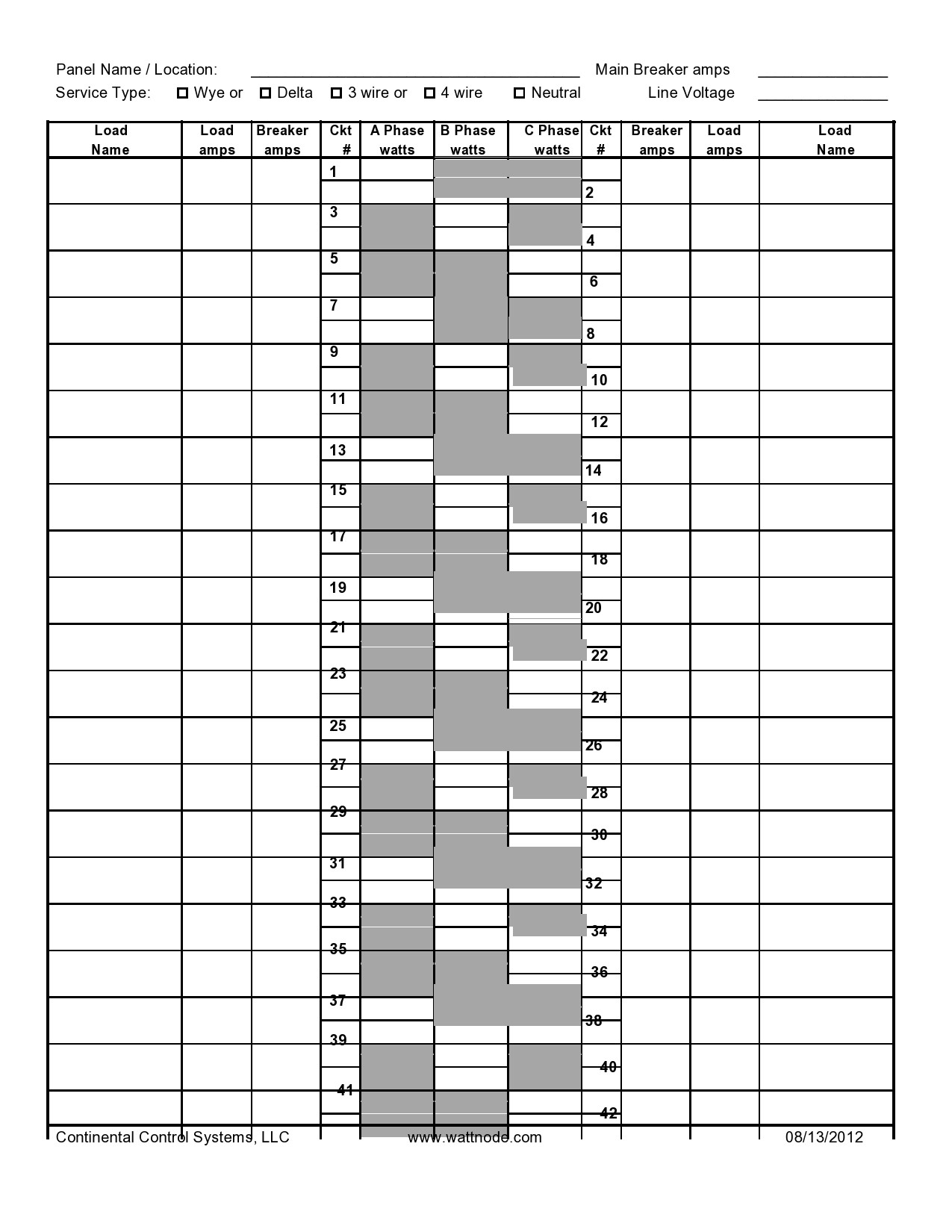

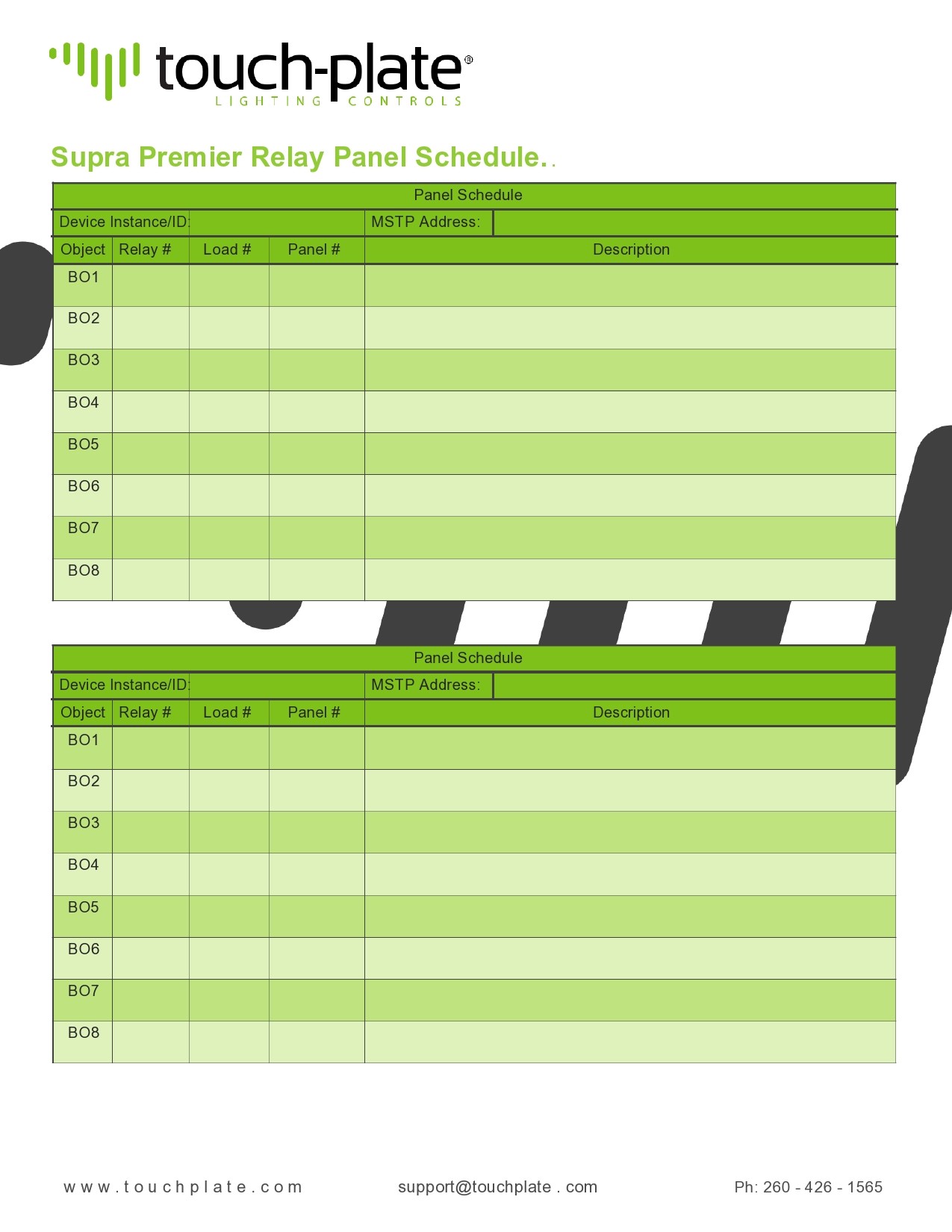

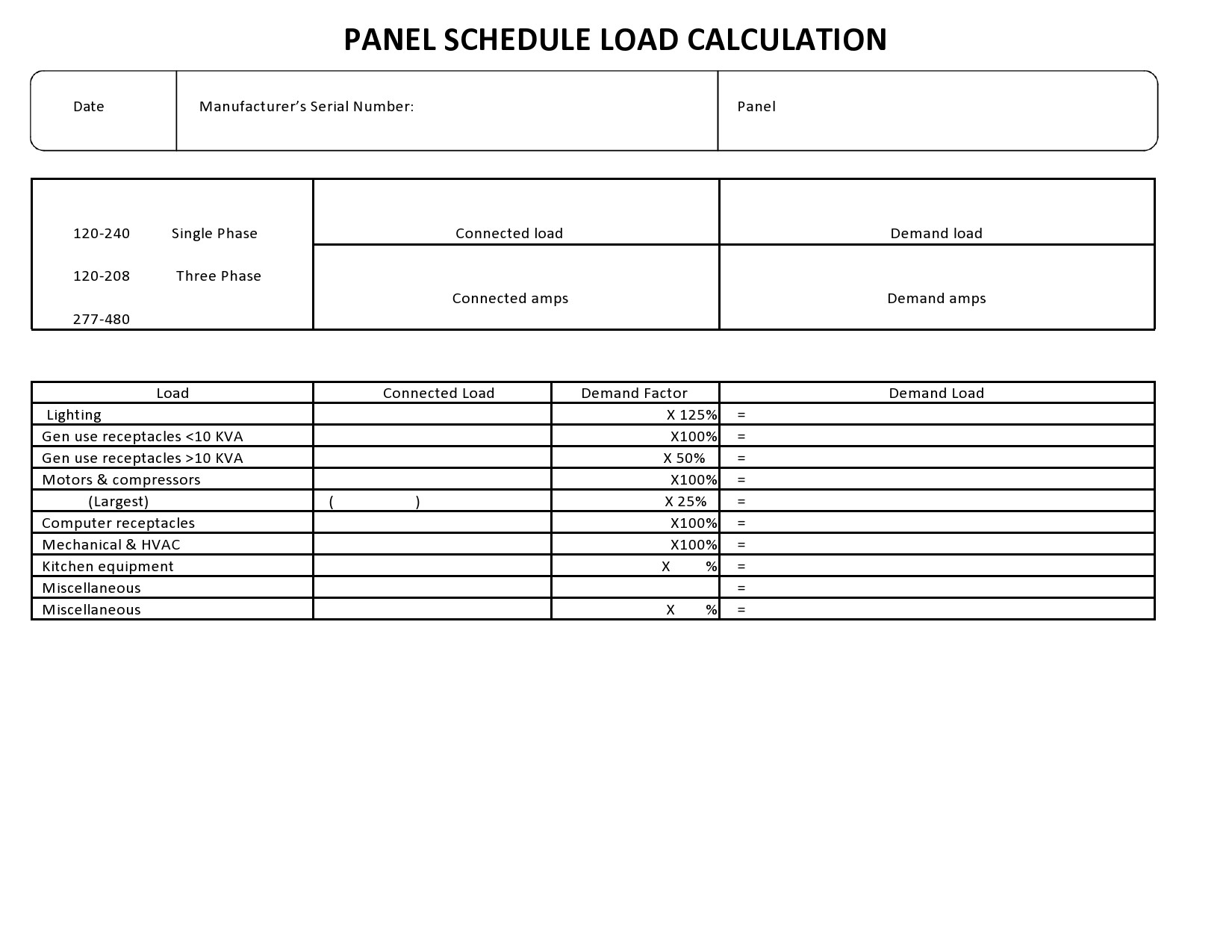

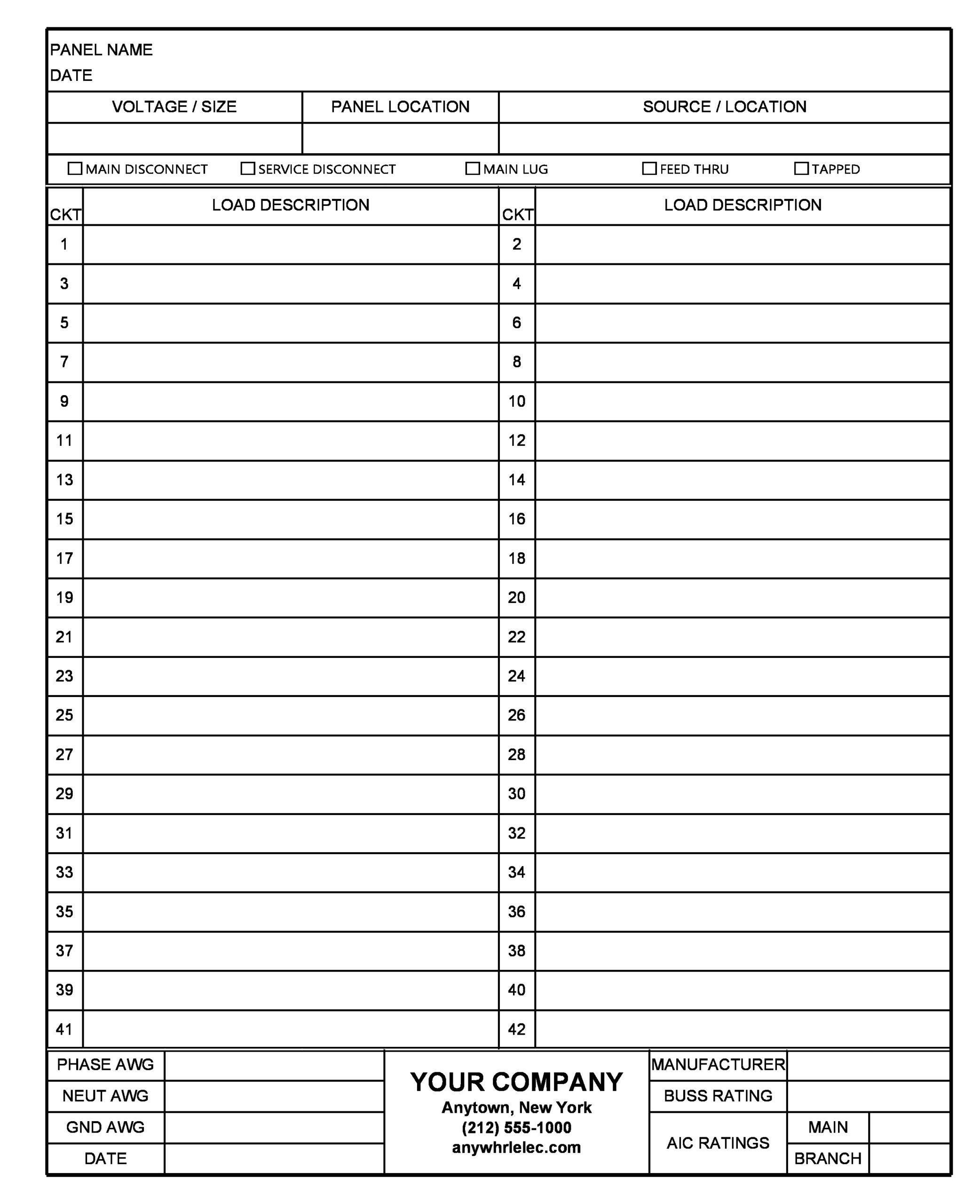

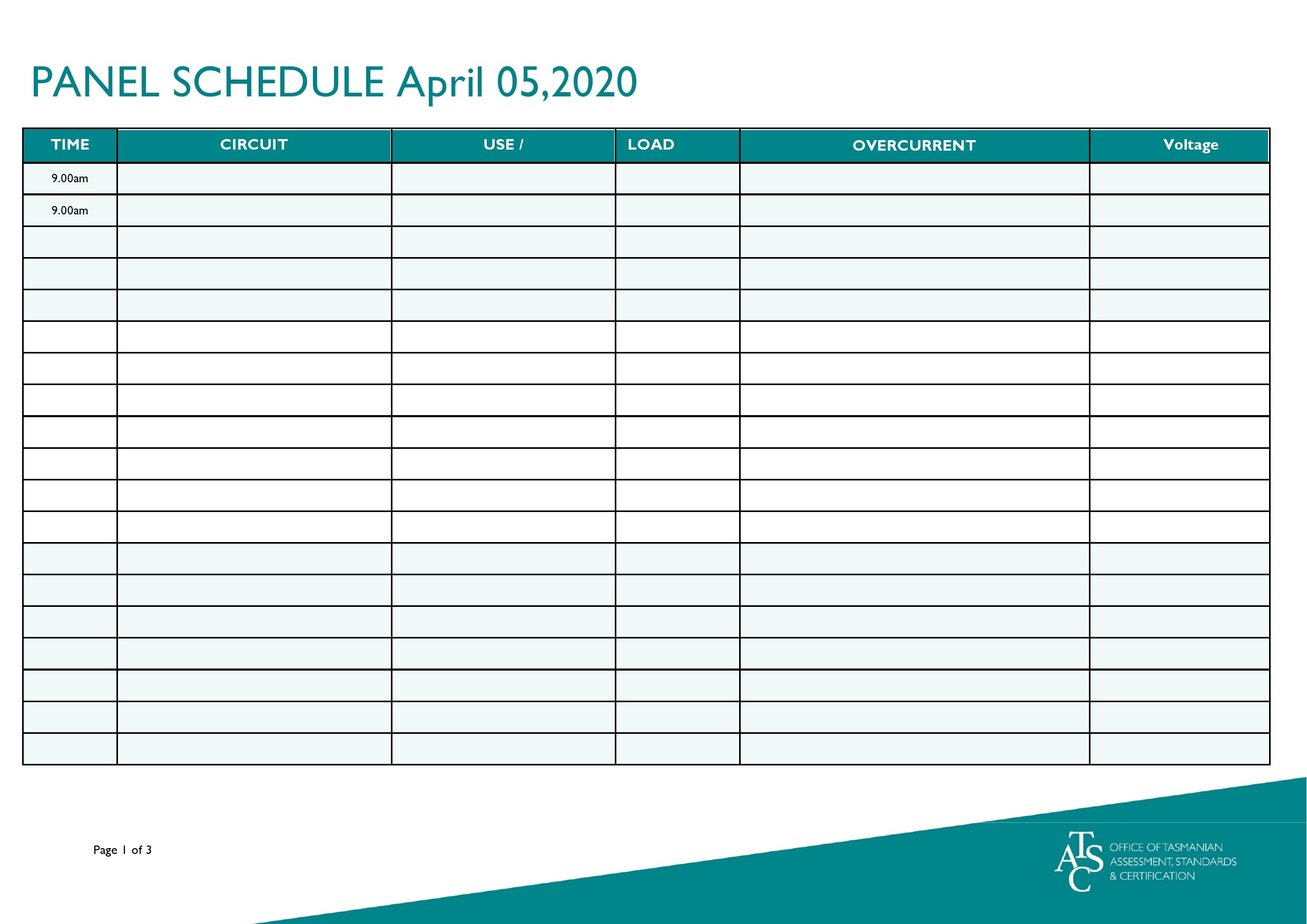

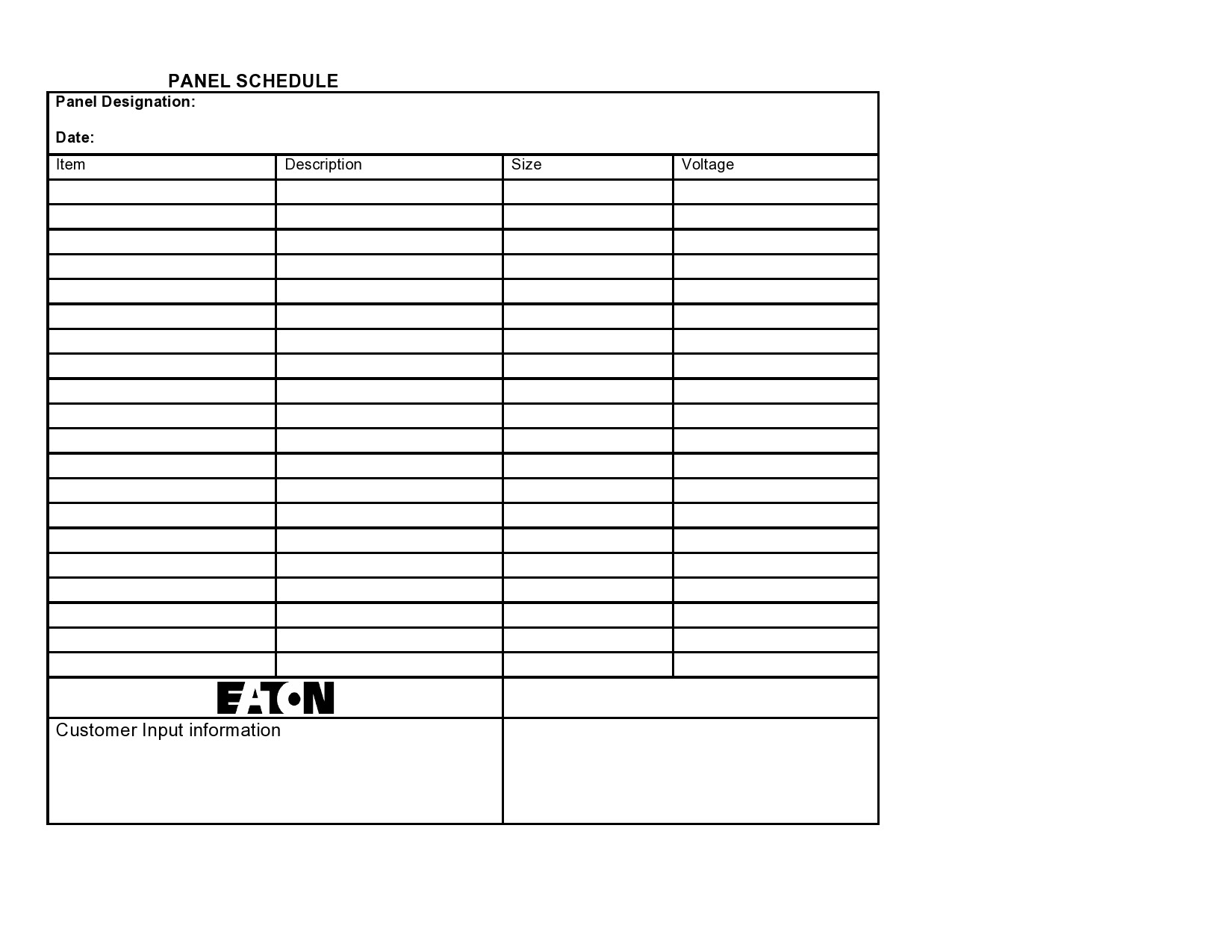

- 1 Panel Schedule Templates

- 2 What is a panelboard schedule?

- 3 Electrical Panel Schedule Templates

- 4 What does a panel board schedule show?

- 5 Importance of panel schedules

- 6 How to make a panel schedule?

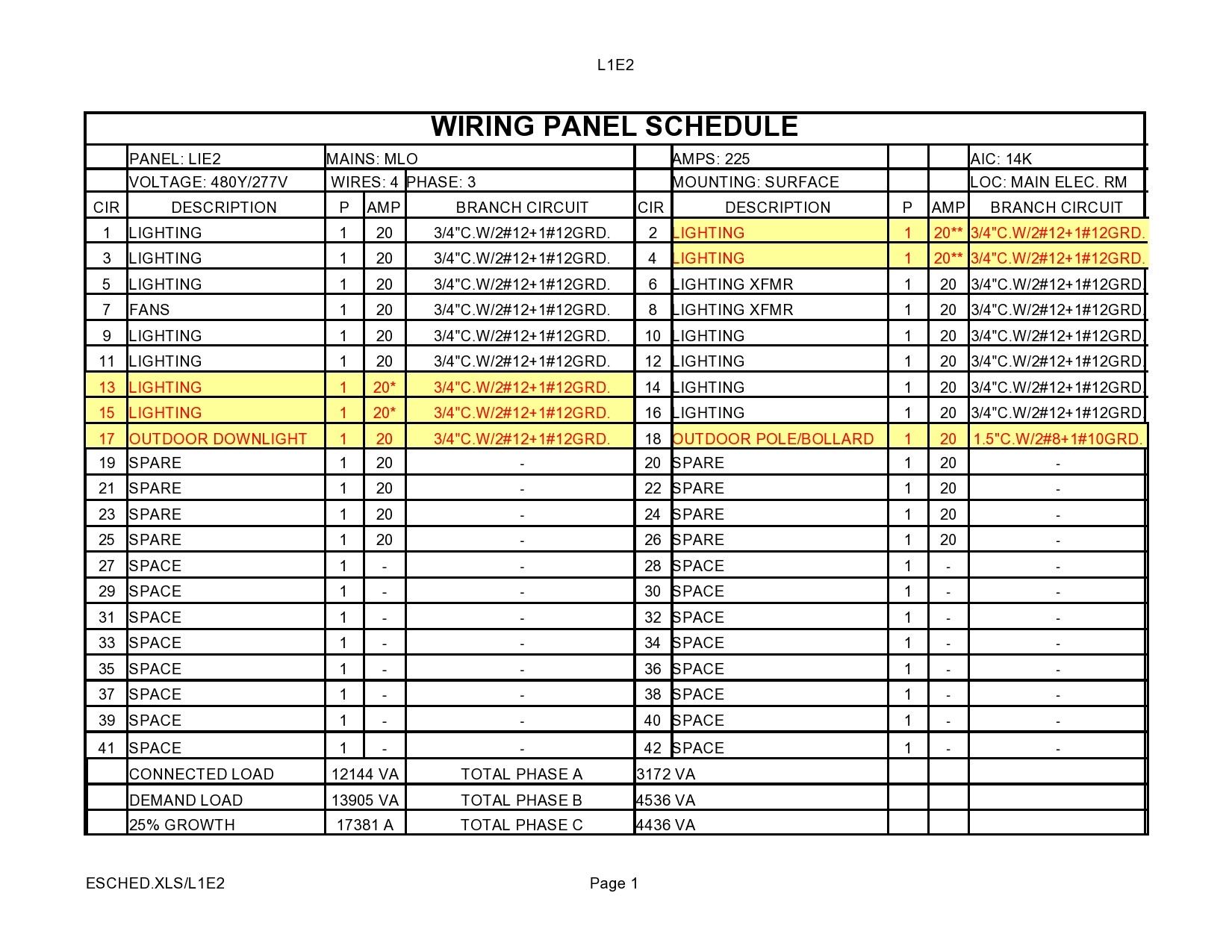

- 7 Fillable Panel Schedule Templates

- 8 Types of electrical panel schedule templates

- 9 What do process and non-process loads mean?

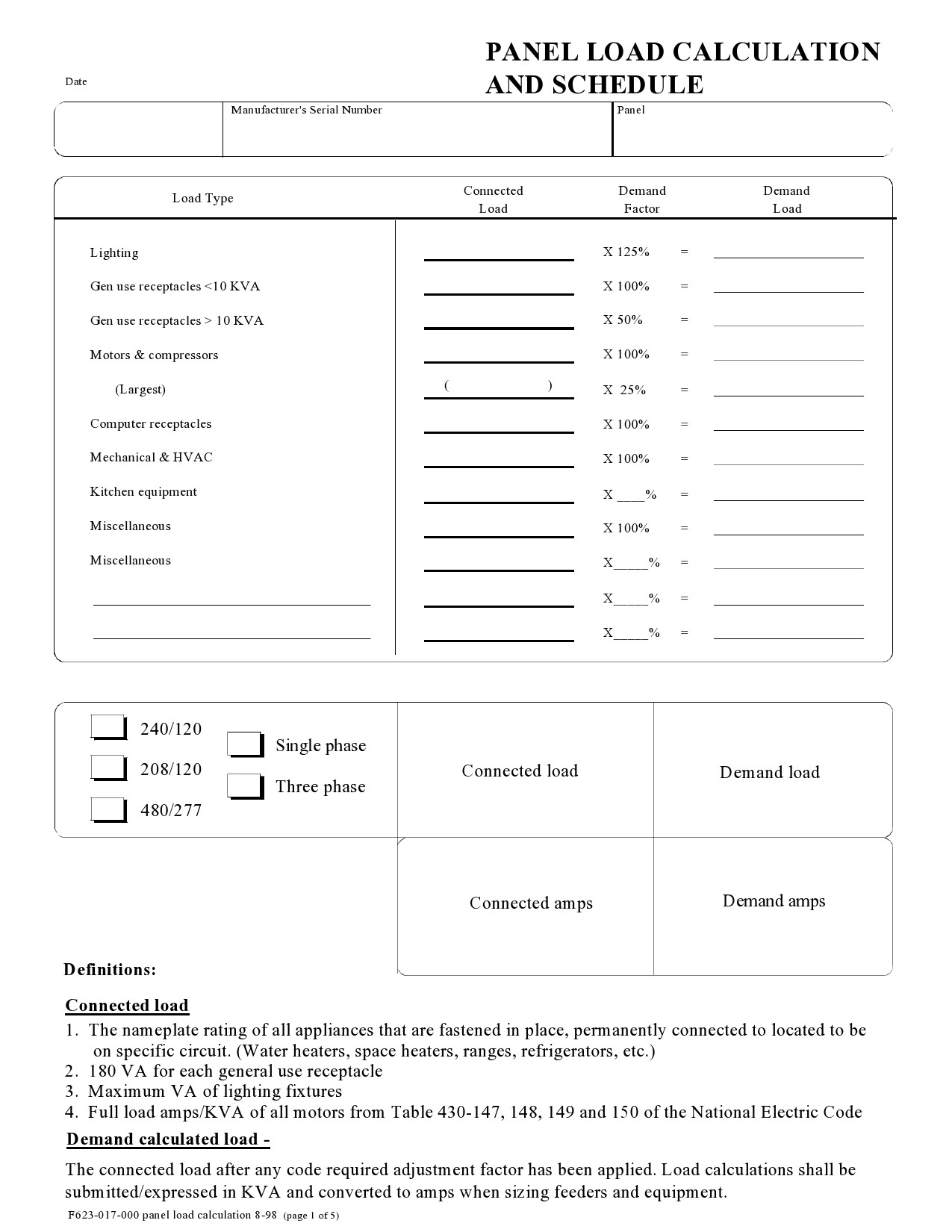

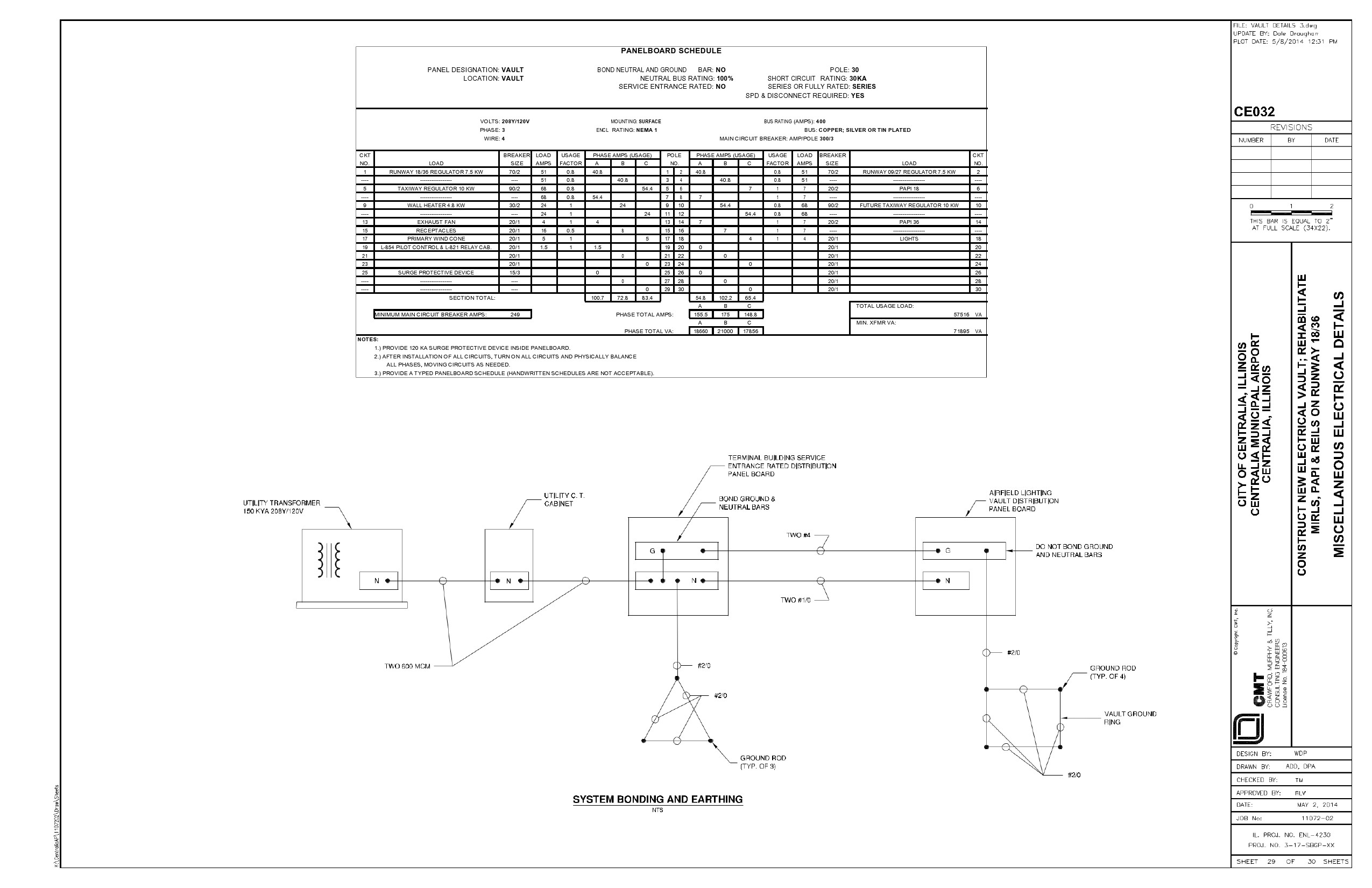

Panel Schedule Templates

What is a panelboard schedule?

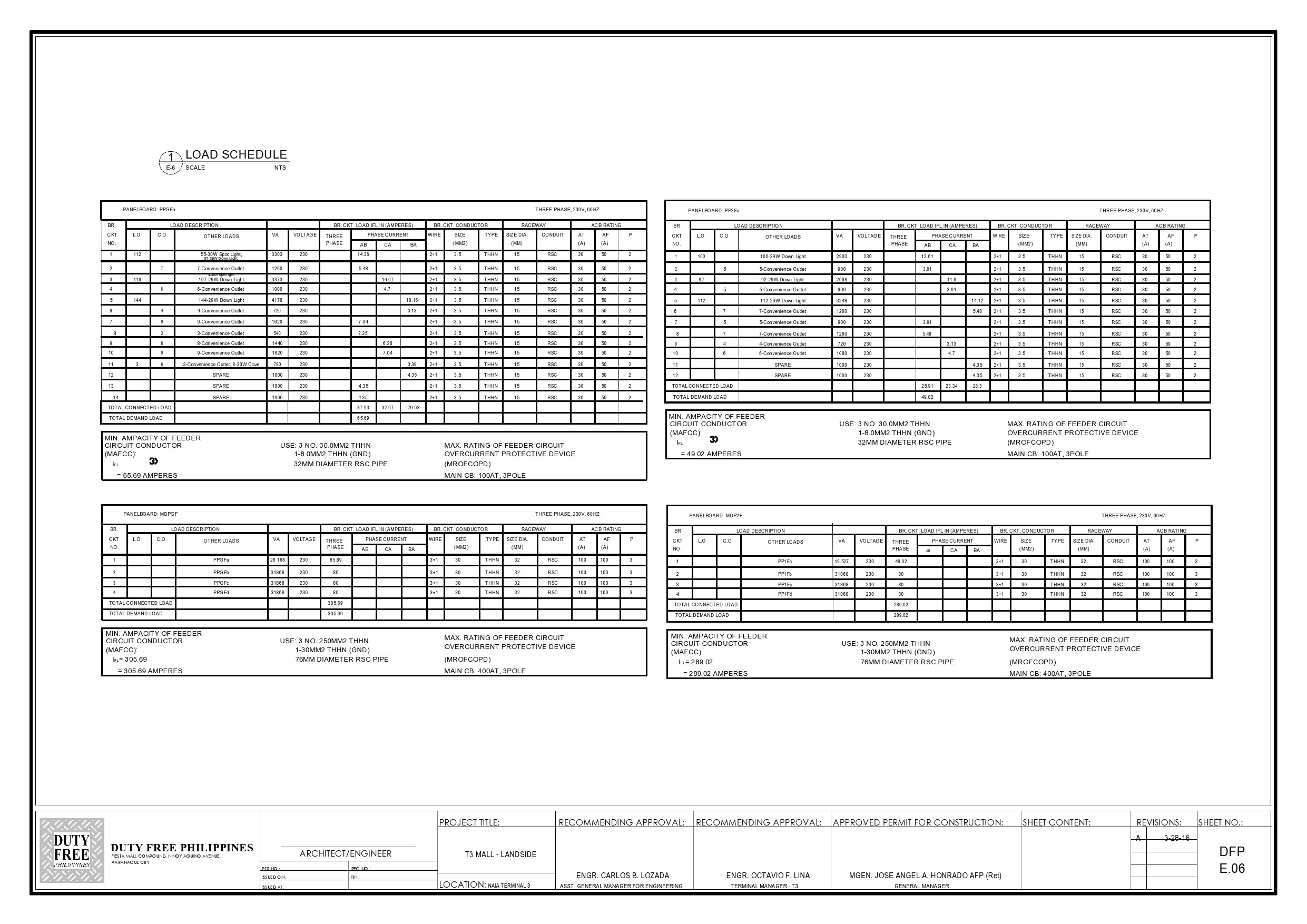

Electrical experts use an electrical panel schedule template to create a panel board schedule. It is a critical schedule used by electrical experts to design different projects and to determine how much power is needed for their installation and operation.

Electrical engineers use a panel board schedule to assess overload issues and install the relevant safety systems. Power schedules provide accurate documentation and design for electrical machinery. A fillable panel schedule template can be created before connecting or after connecting circuits.

An electrical panel schedule template is used as a guide to electricians when they need to identify which machine needs power. It is different from an equipment schedule because the latter guides on the type of wiring and power are required for certain equipment in terms of ampacity, volts, or phase.

In a busy commercial site, there are usually a lot of panels meaning there are also a lot of schedules to deal with. The electrician should be keen to identify correctly which panel powers which equipment or machine.

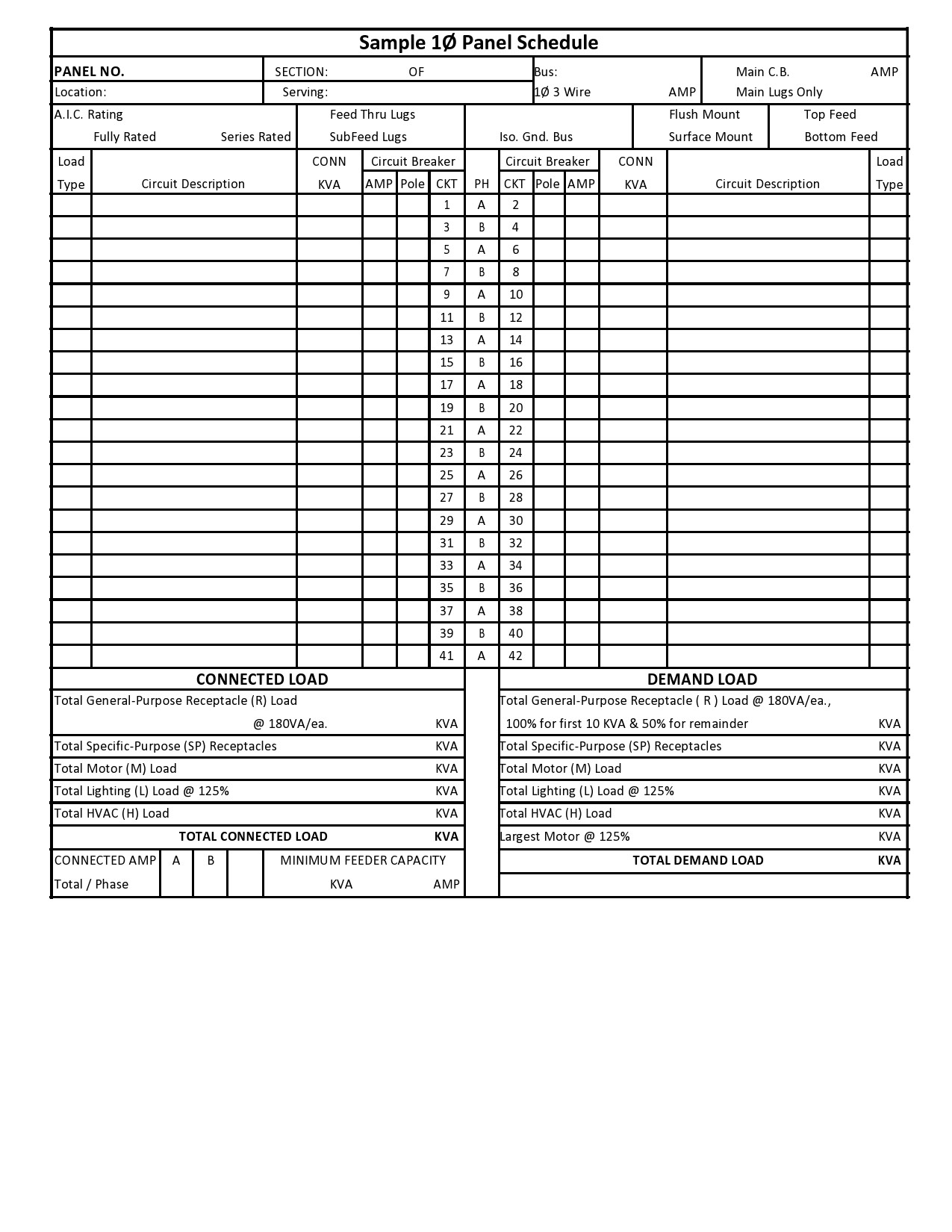

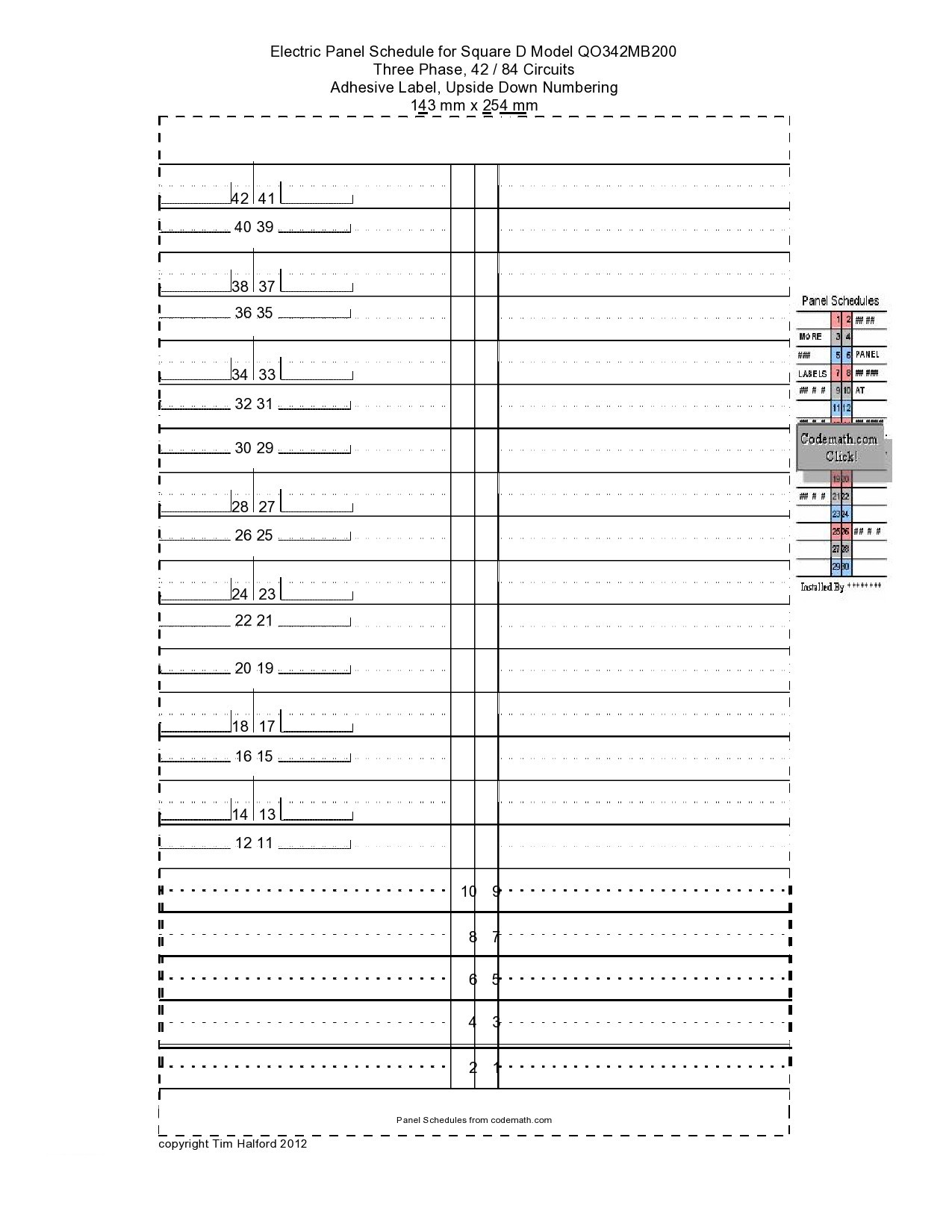

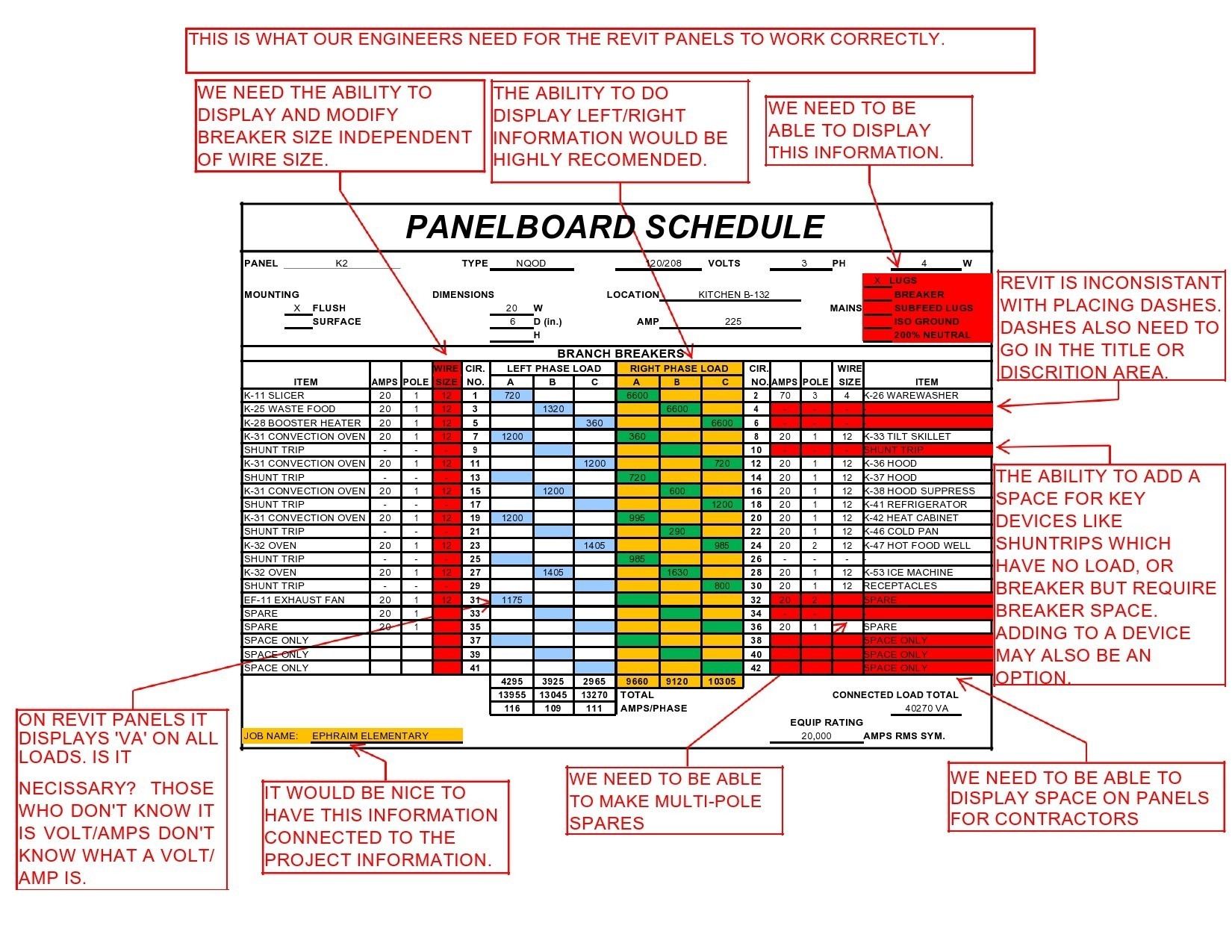

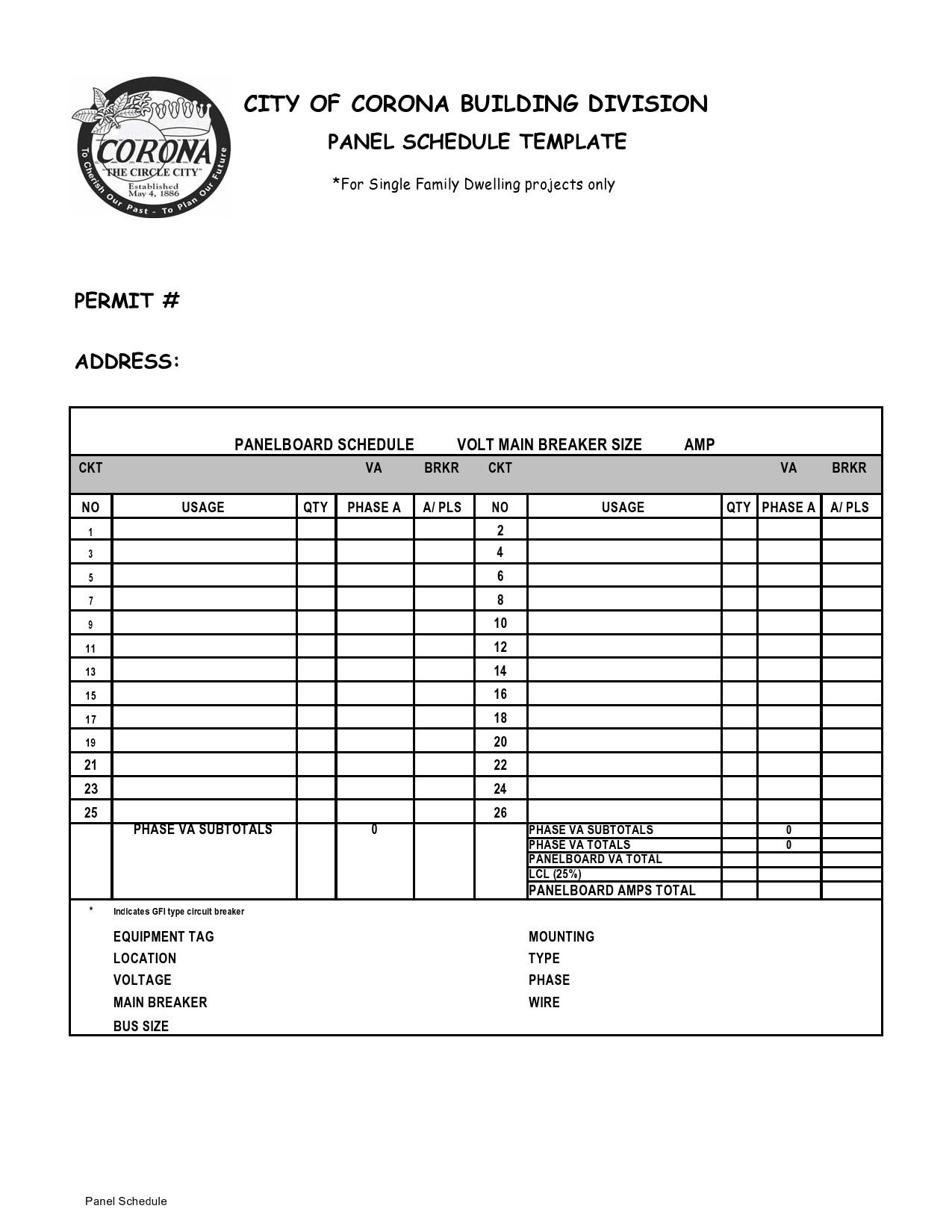

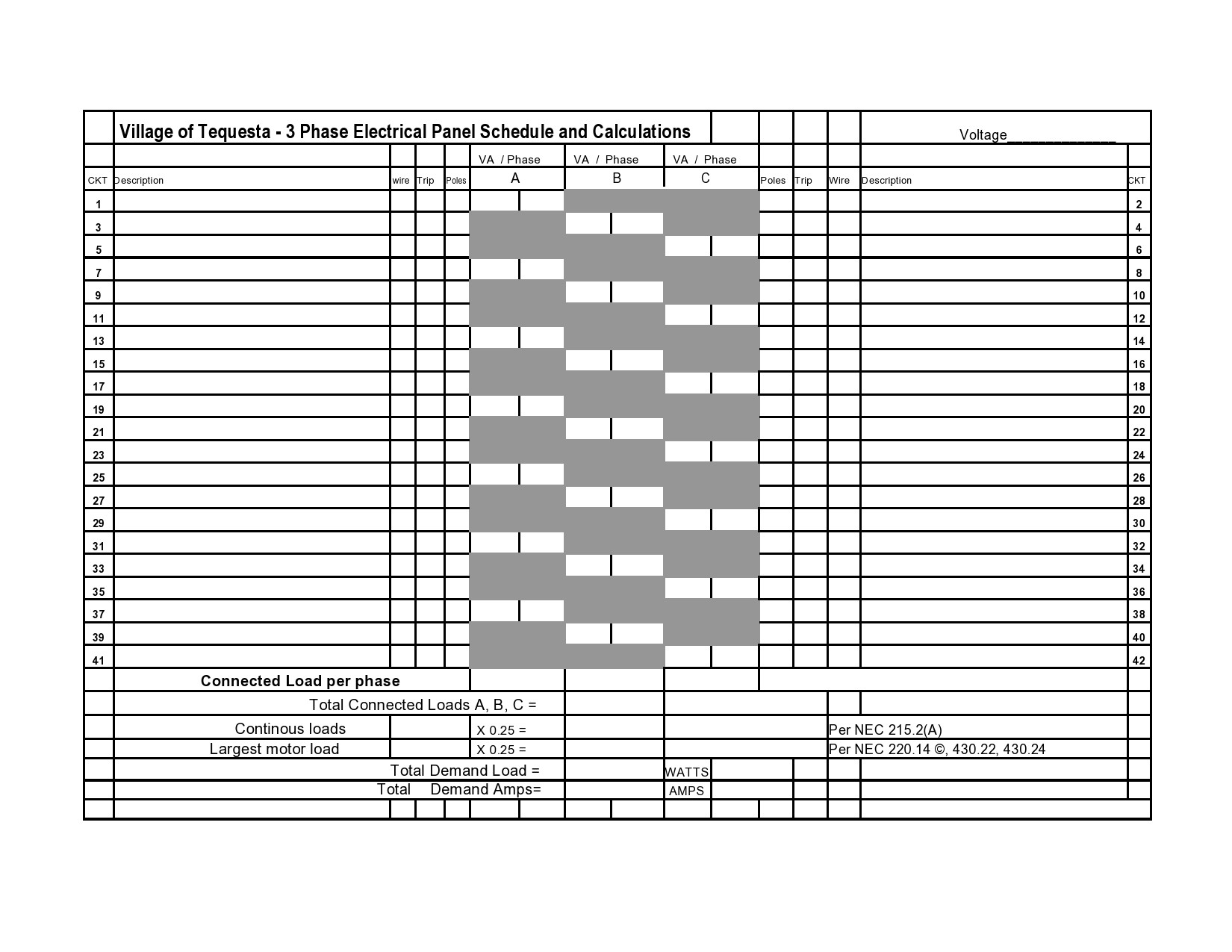

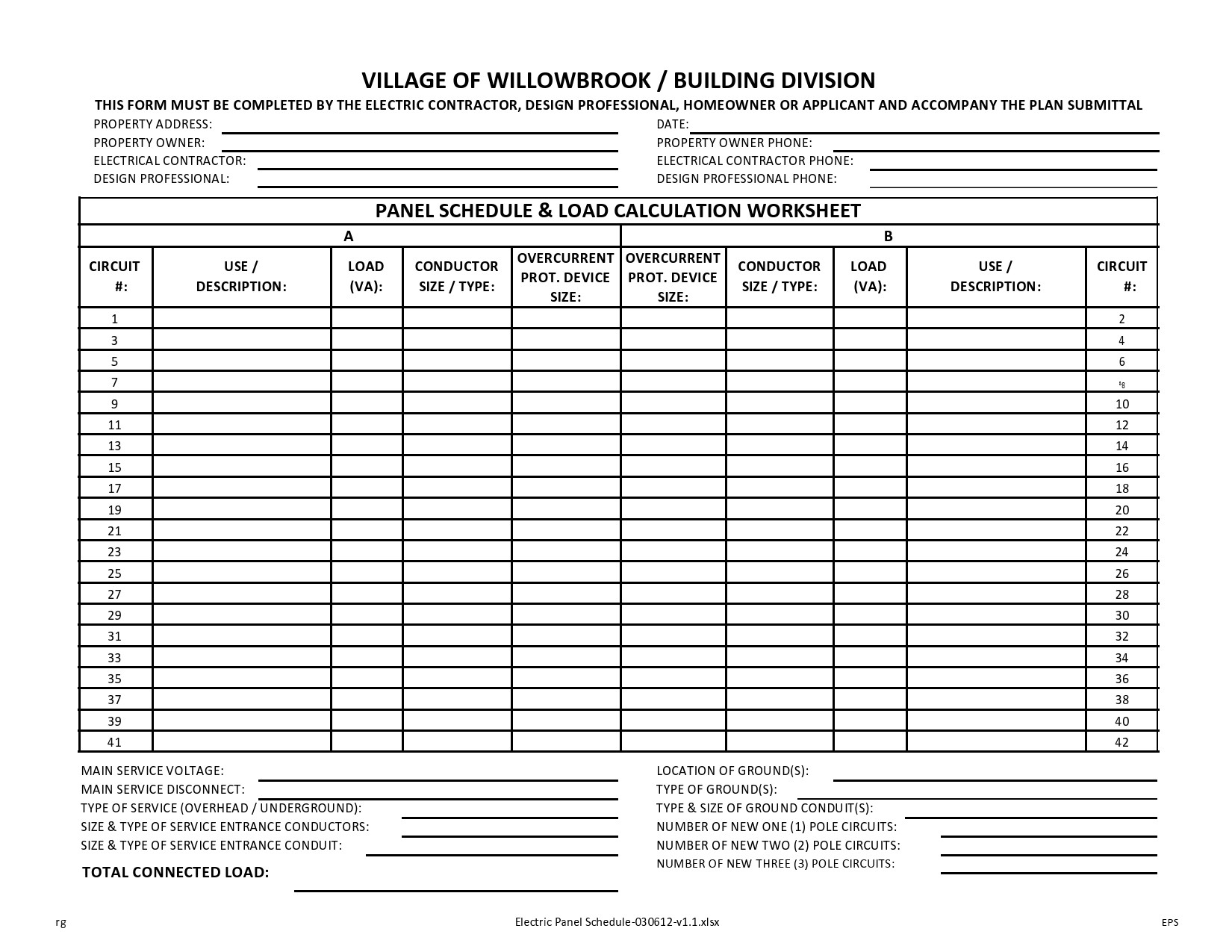

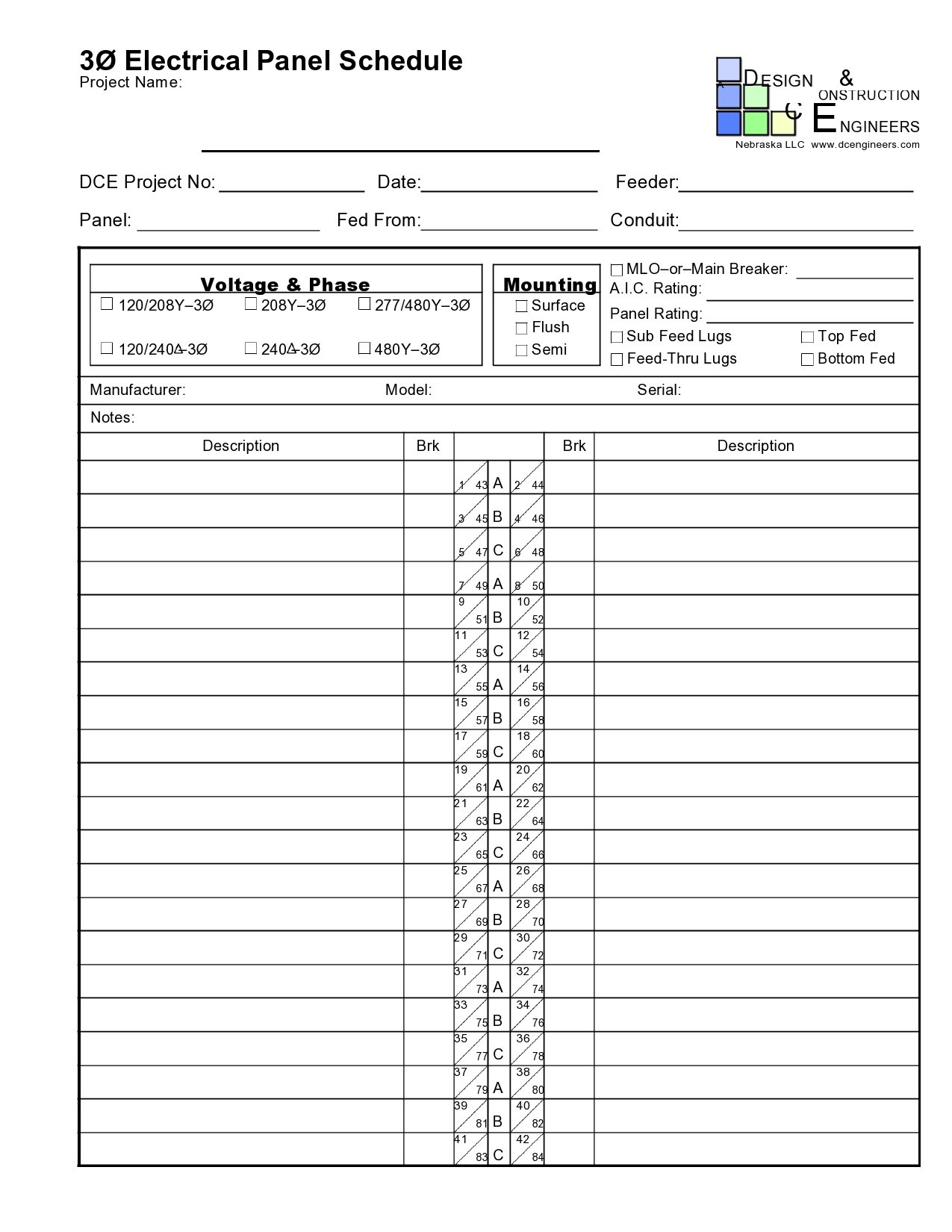

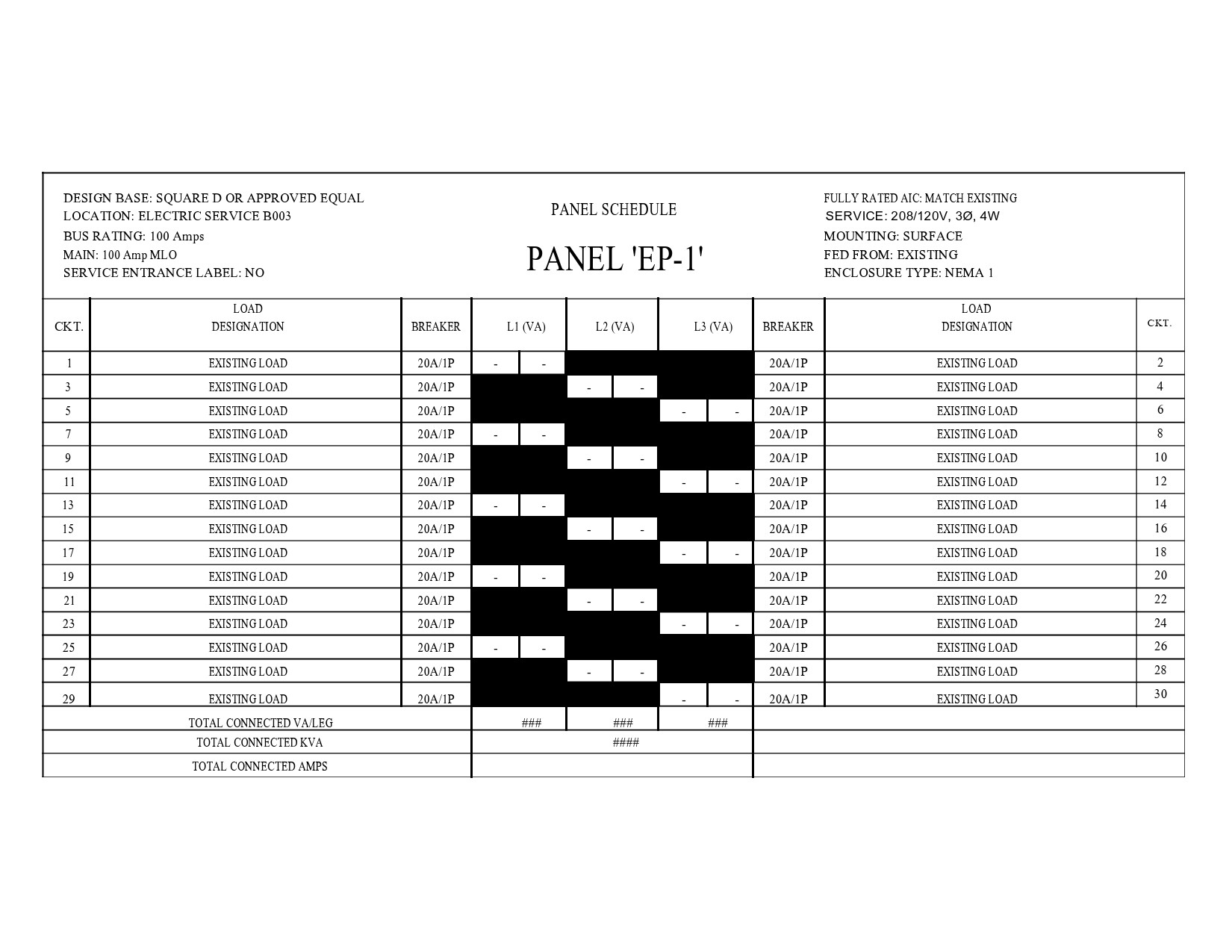

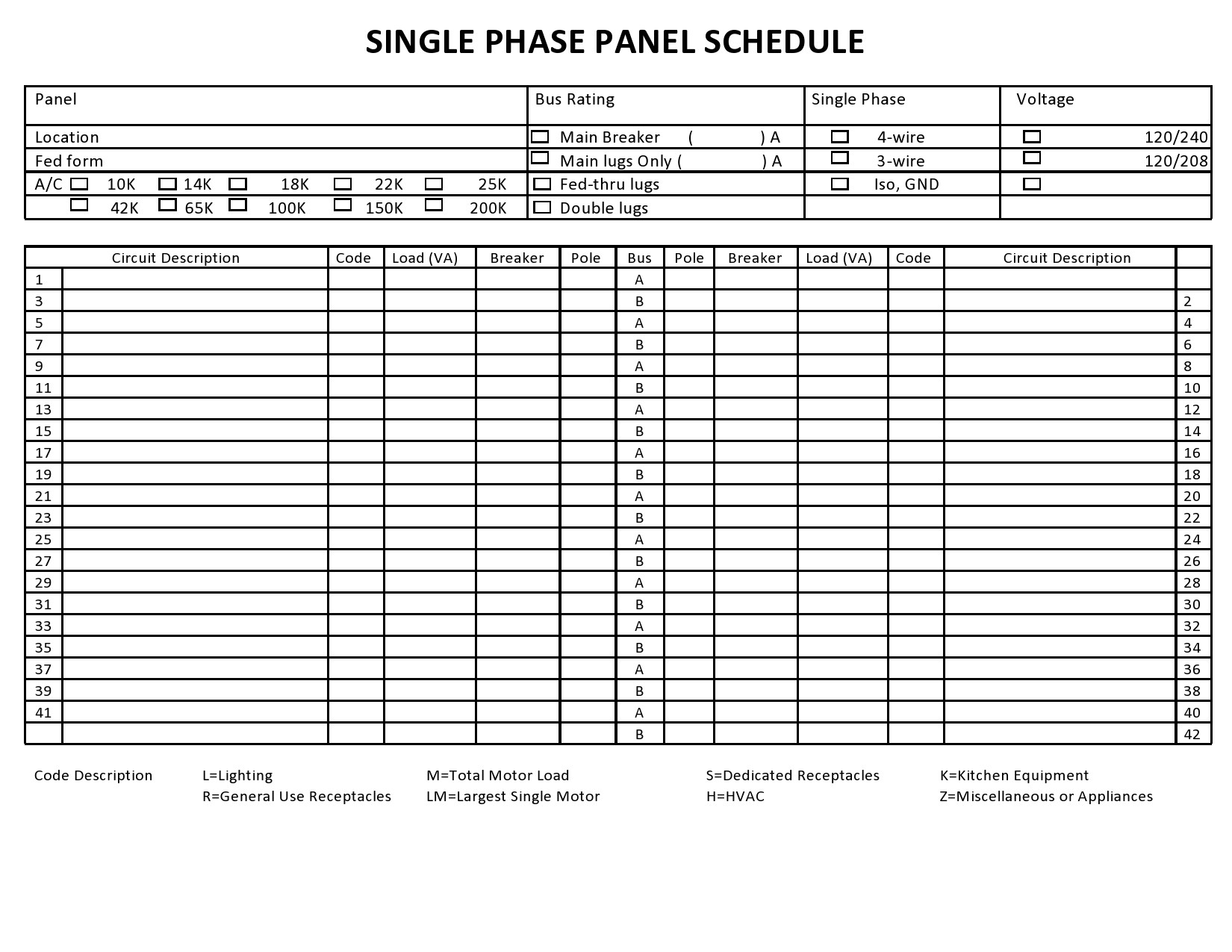

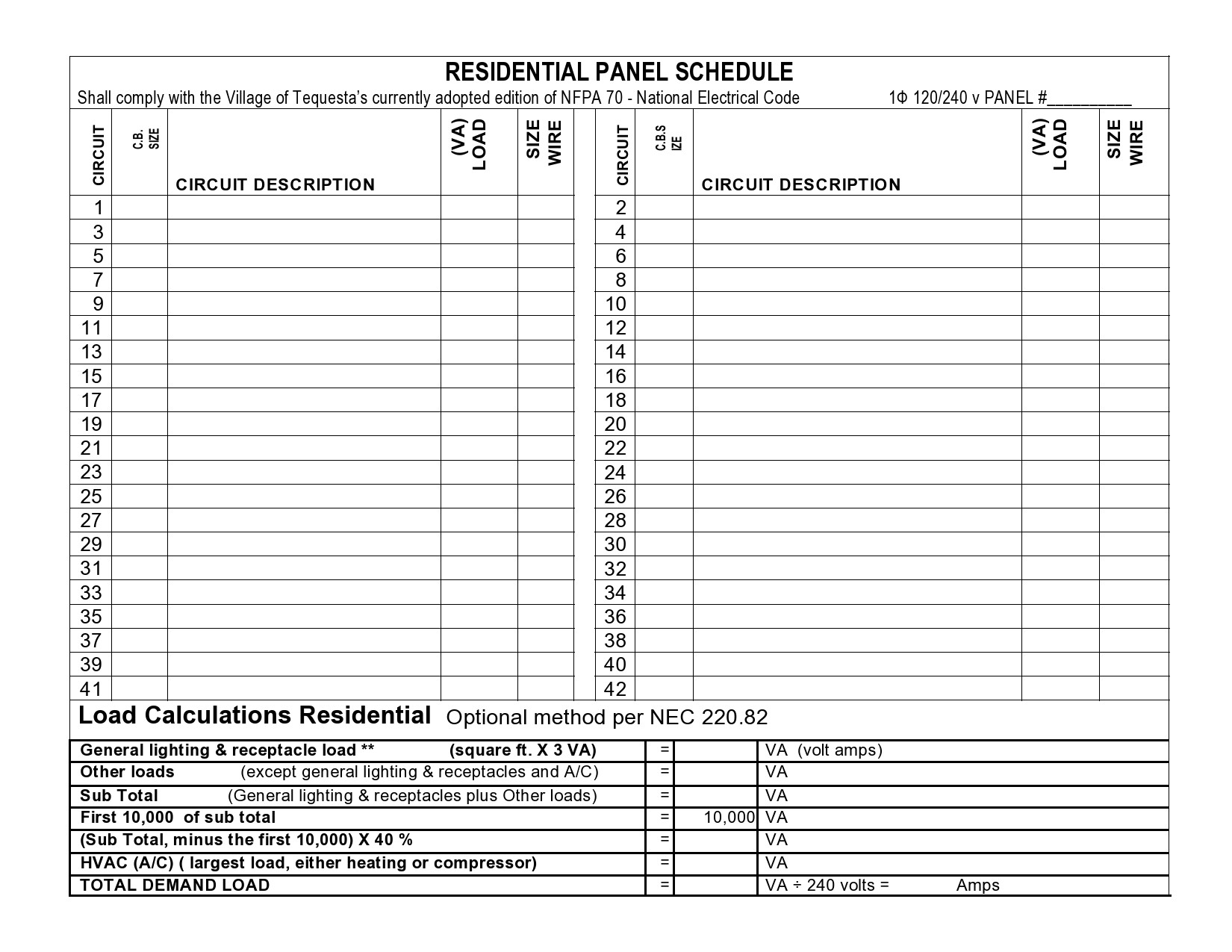

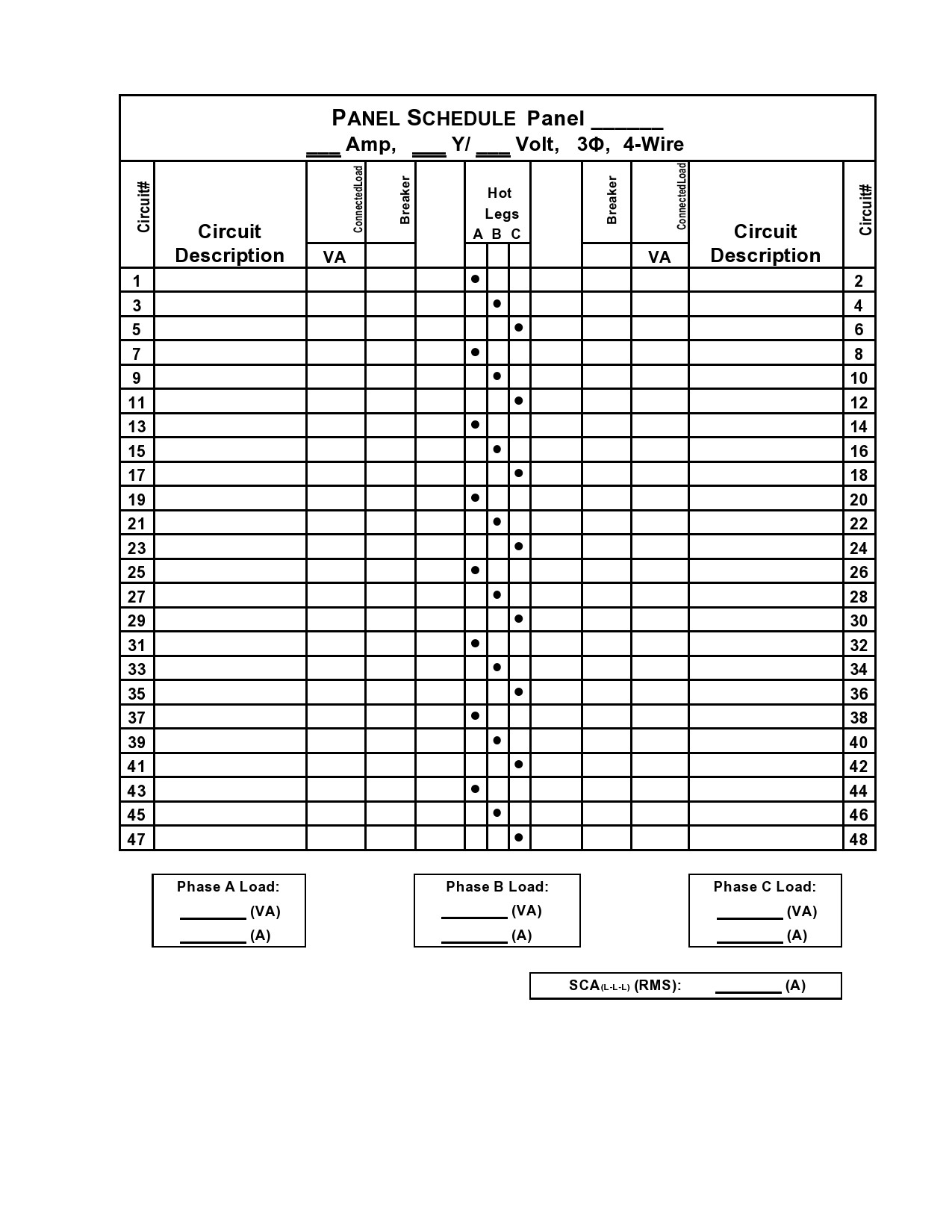

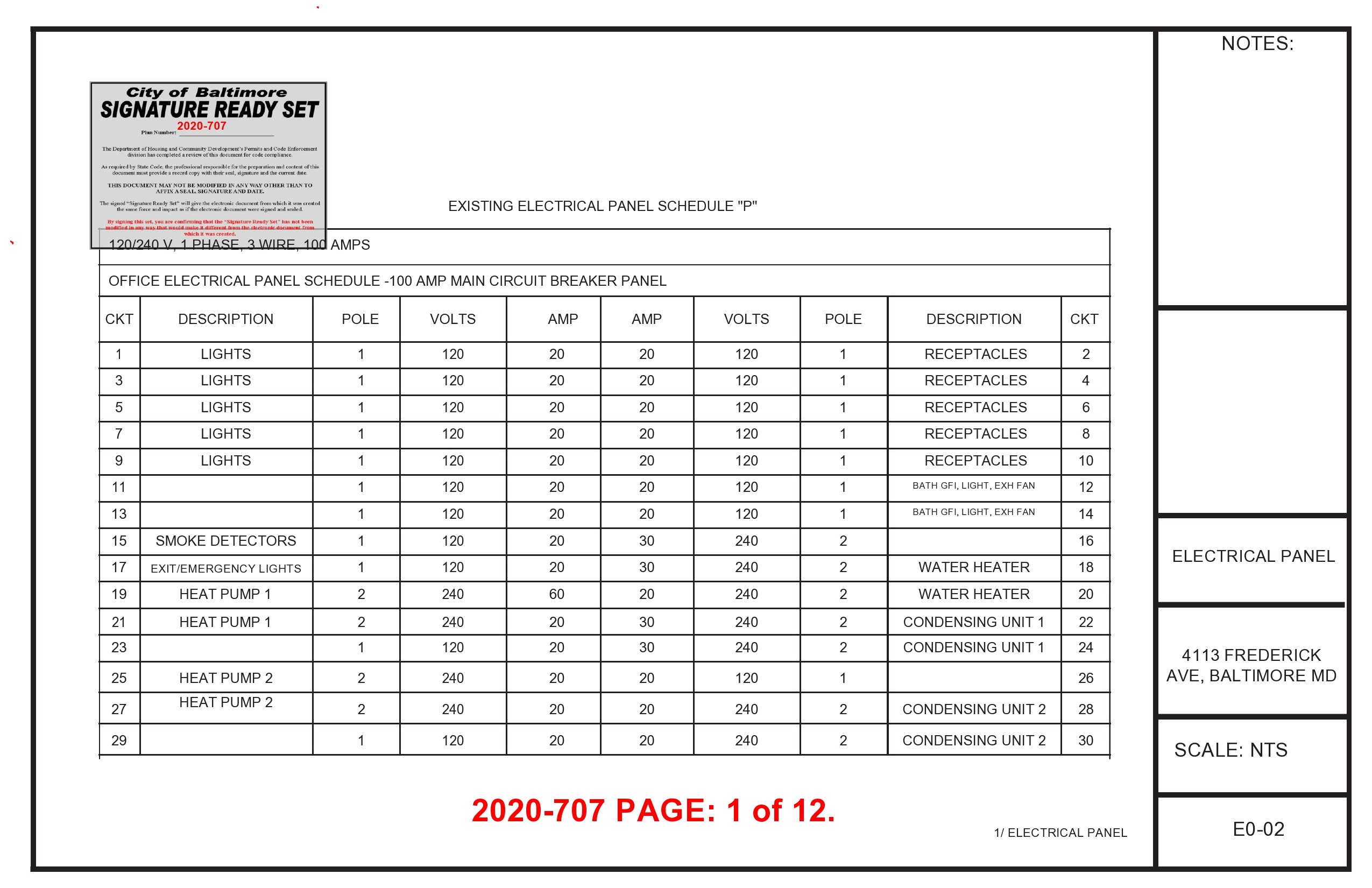

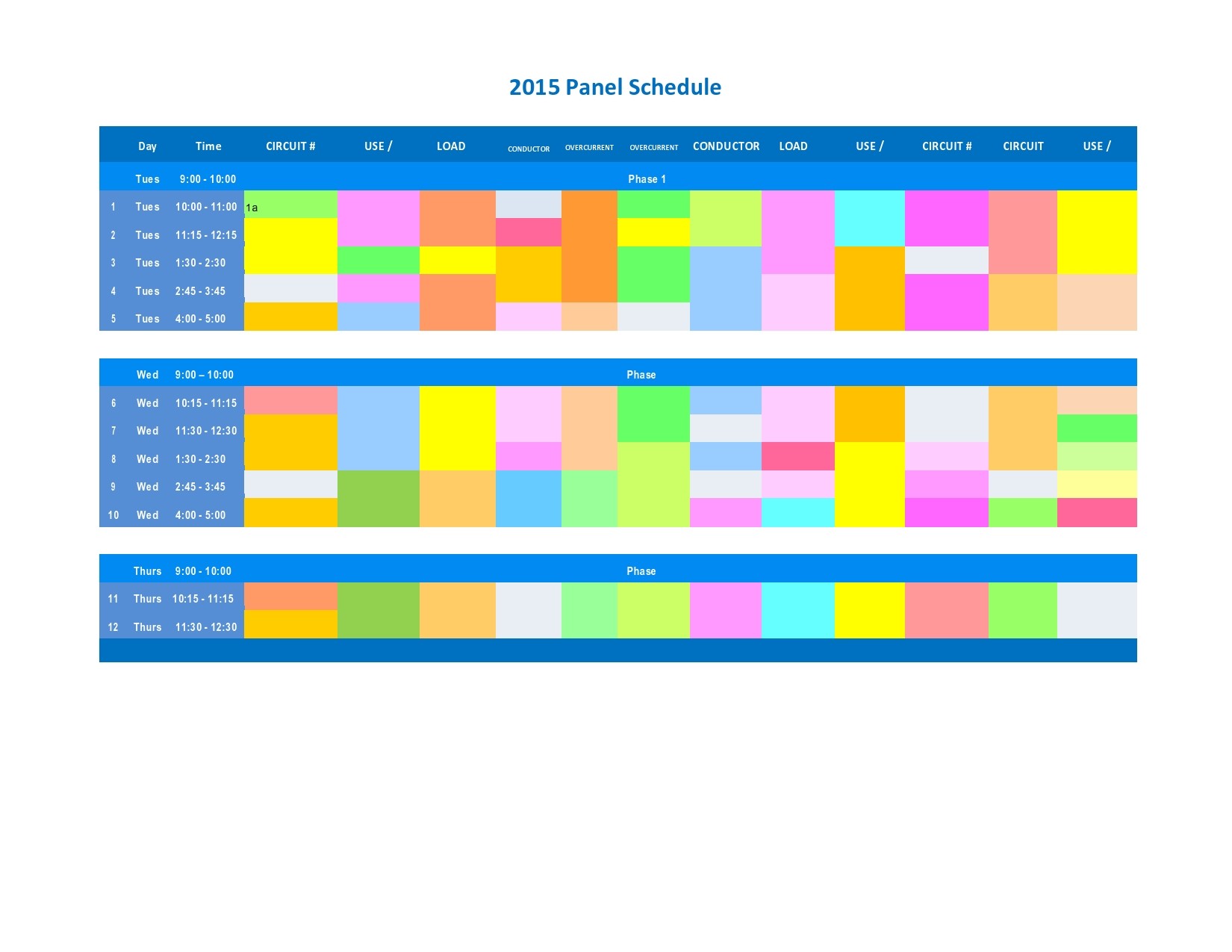

Electrical Panel Schedule Templates

What does a panel board schedule show?

When an electrician is new to a commercial site, the first thing they should request is the fillable panel schedule template that shows the details of panels and machine connections. The panel board will guide them by showing these details.

- Equipment name

These could be apparatus, appliances, cables, conductors, insulators, motors, pumps, poles, fans, etc.

- Circuit number

The circuits can be given any numerical digit but it must be unique to avoid confusion. The numbering can be done according to the section the circuit serves. A circuit is simply a power connection from point A to point B through which electricity can flow. Circuits are made of wires of different sizes depending on the amount of power required.

- Circuit breaker size

Depending on which equipment the breaker has served, some of them are big while others are small in terms of amperes. The smallest can be 2 amps while the largest can be 32 amps, 1000 amps, 5000 amps, or more.

Circuit breakers for lighting circuits are small but those that serve cookers, freezers, or water heaters are large because the appliances require more amperes/voltage. Breaker size helps electricians to decide the size of wires to use.

- Number of poles/phases

A pole or a phase means the total separate circuits controlled by a switch. Mostly, poles can either be single or double. A single-pole switch is assigned to one circuit while a double pole is assigned two circuits within the same button. In reality, these are two separate circuits joined to one button. Some poles are three-pole breakers requiring three-phase power.

Importance of panel schedules

Making work easier

Panel schedules can be created from an excel panel schedule template. Without the schedule, an electrician cannot fix electricity infrastructure in a site effectively. It helps guide them from point A to point Z at the phase when they are pulling wires.

The electrician refers to the fillable panel schedule template to figure out which devices will be served by the wiring while minimizing the number of pulls as much as possible.

Estimating the right electrical load

There are times of the day when electricity use is at its peak, especially in the evenings, weekends, and holidays. An electrician should correctly estimate the amount of electrical load during this time and also the normal hours of the day. The details contained in an electrical panel schedule template help them calculate their estimates correctly.

Adding extra loads

A site or facility might require to be expanded in the future. They may also require adding extra loads due to the need for more gadgets. Without the details in a fillable panel schedule template, the owner might overload some circuits and affect the breakers, sockets, main supply, or wiring.

Allowing future expansion plans

When there is a need for expansion, the electrician uses the panel schedule to advise the owner which circuits shall supply the extension. It helps avoid electricity dangers due to overworking a single circuit.

Better power management strategies

A panel schedule helps provide a power management strategy for keeping power load balanced in the periods between peak and off-peak hours. The home of the facility owner benefits from keeping electricity costs regulated and thus saves money every month.

Installation of the right control system

Electrical engineers use the details in an excel panel schedule template to decide the size of control systems, conduits, and conductors to buy for installation. It helps them design the infrastructure for future loads.

Without the proper provision of future loads, an entire electrical system will have to be overhauled to allow redesigning for accommodating extra loads. Without this action, there could be risks of fire, frequent breaker tripping, appliances failing to work, etc.

Prevention of accidents

The safety standards set by OHSA require businesses to fill out their electrical panel schedule template at the start of the electricity installation process. They should also schedule the spare breakers that are not in use by labeling them spare and keeping them turned off.

It is dangerous to keep a spare breaker on or to turn off a breaker when it is on. Having a correctly filled fillable panel schedule template can help prevent an electrical accident at workplaces and homes.

Labeling equipment

A fillable panel schedule template helps electricians label equipment correctly. They label the breakers, circuits, poles, etc. When the equipment is labeled correctly, it saves business time spent going through the electricity system to identify how the circuits are running. It also improves electrical safety within the facility.

Avoiding dangers from spare power breakers

Spare breakers should be labeled correctly as spare and numbered properly. Without labeling them, someone might assume they should be servicing a certain circuit and switch them on. By switching them, they will be interrupting power flow which could lead the property damage by electrical fire or appliances damage due to overloads or surges.

How to make a panel schedule?

To create a detailed panel schedule, you may first download a panel schedule example to help you understand the details you require. The panel schedule example can be Excel or any other file format. Here are the steps to follow when making a panel schedule.

- List all loads in the entire installation

Electrical loads mean electrical components that are consuming power within the facility. When an electrical current reaches a point where it is changed into a different energy, that point is called a load. It can be changed into light through an electric bulb, heat through a heater, turn a motor, or charge a battery.

- Specify the loads

After listing the loads, specify each type of load. There are different types of loads.

- Resistive loads – they turn electricity into heat by resisting its flow. An example is light bulbs and heaters.

- Inductive – they change electrical current into magnetic energy. Examples are transformers, coils, and electric motors.

- Capacitive – they store small amounts of energy to power a gadget. Examples are motors, radios, TVs, phone circuits, etc.

- Combinative – they combine two or more types of energy to work. Examples are radio tuners, cathode ray tubes for TV or monitors, and single-phase motors.

You can count the number of loads by counting the number of sockets and switches within the facility.

- List the electrical properties of the loads – Each load is serving a specific appliance that requires a unique number of amperes to work. Some loads require 6 amps, others 20, 100, 600 amps, etc. Consider factors such as voltage, efficiency, etc. Categorize and name each load as per the amperes required to serve it.

- Categorize all equipment

Divide the equipment into categories guided by the switchboard, load duty, and criticality. A switchboard helps to divide and distribute electricity into several circuits. It contains a fuse for each circuit to offer protection to them. They can load up to 600 V and distribute power in an entire facility.

Load criticality is measured by the importance of equipment. Some equipment must be supplied with electricity to avoid challenges with distribution. For example, places such as hospitals, airports, and 911 centers require critical loads. Determine which area or load in a facility is a critical load.

Load duty means the length of period when a certain load stays on and the time it stays off. Some loads must stay on all the time but others an on for a few hours in a day.

- Determine the approximate amount of power each load will consume

Some loads will consume a small amount of power even when they stay on for many hours. Others will be on for a short time but consume a lot of power. For example, a lighting bulb will consume a small amount of power compared to a heater.

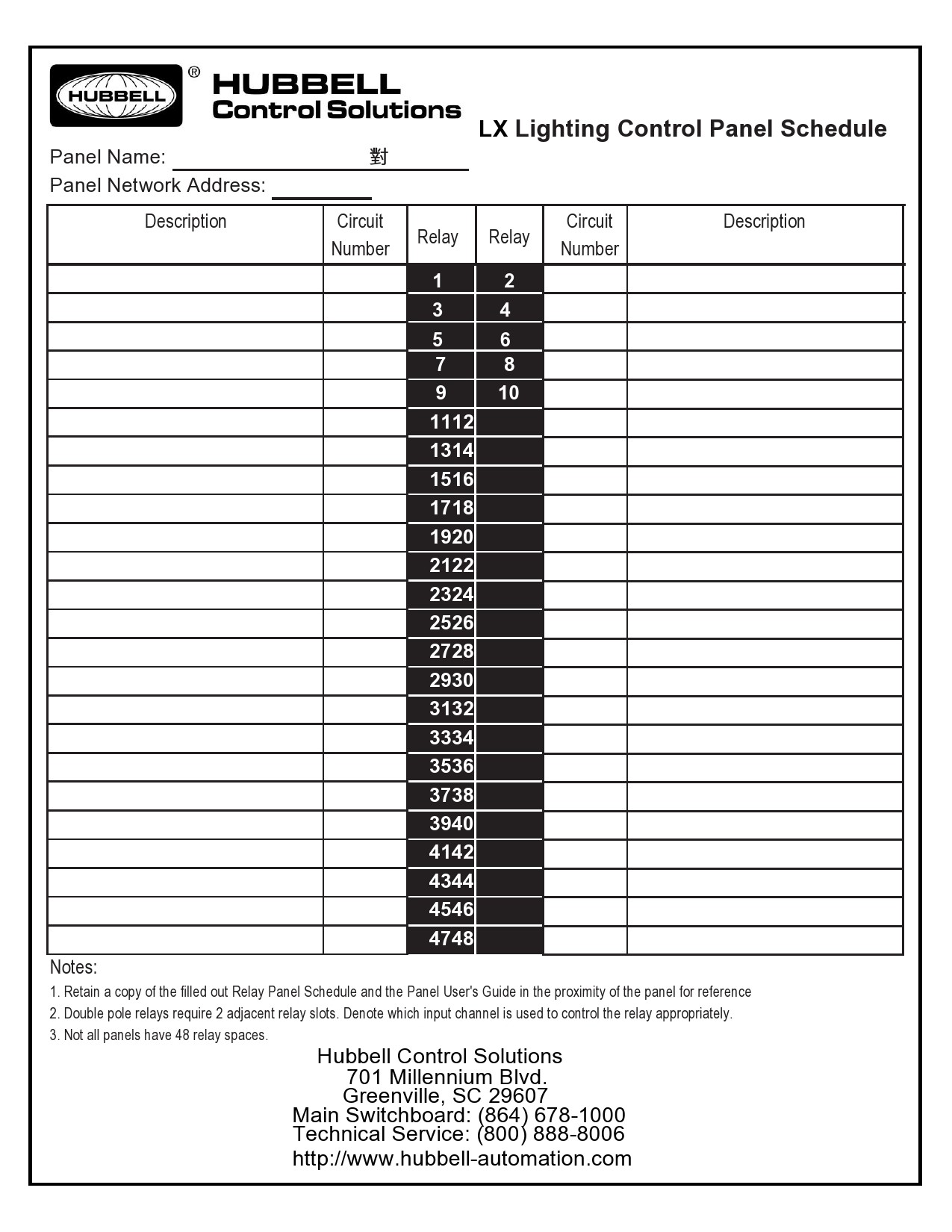

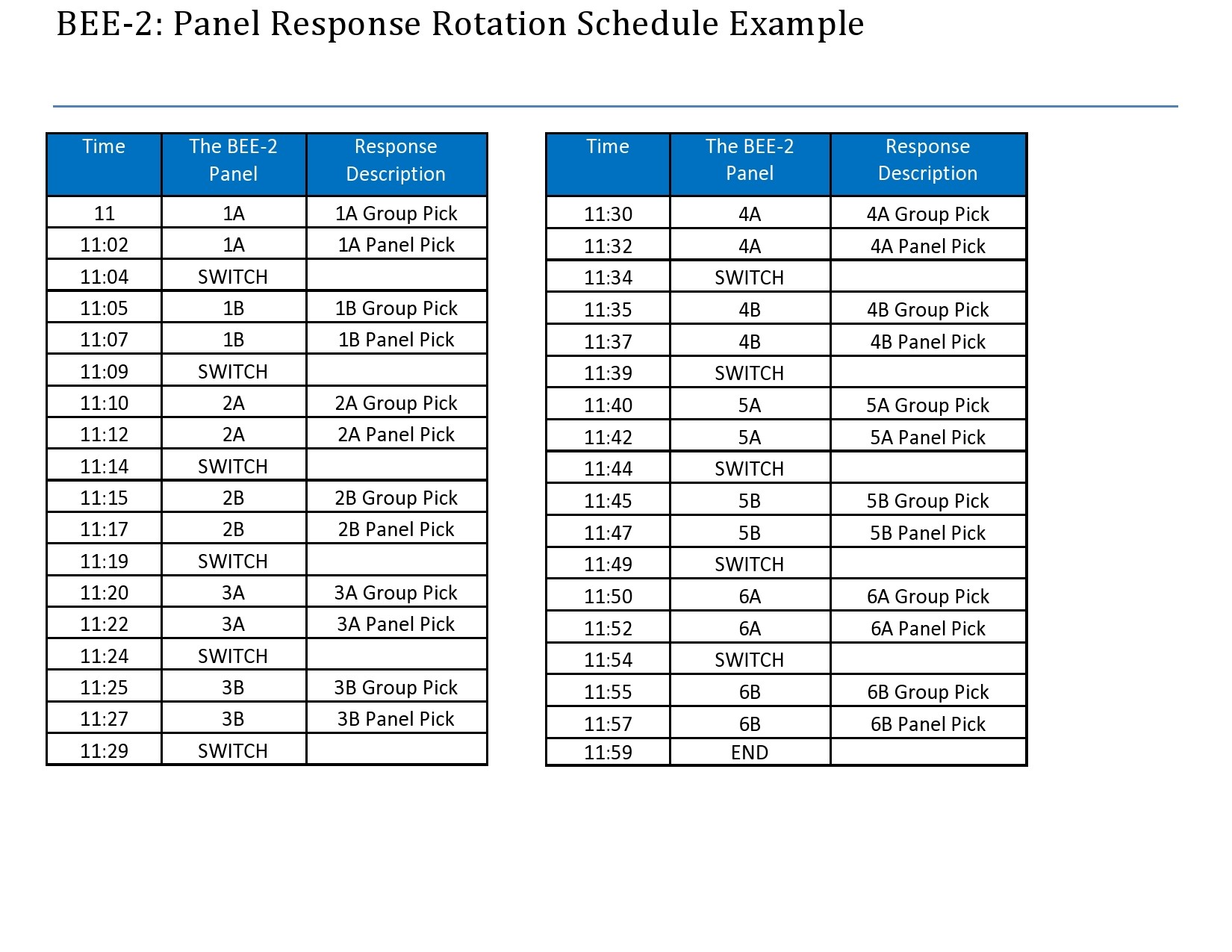

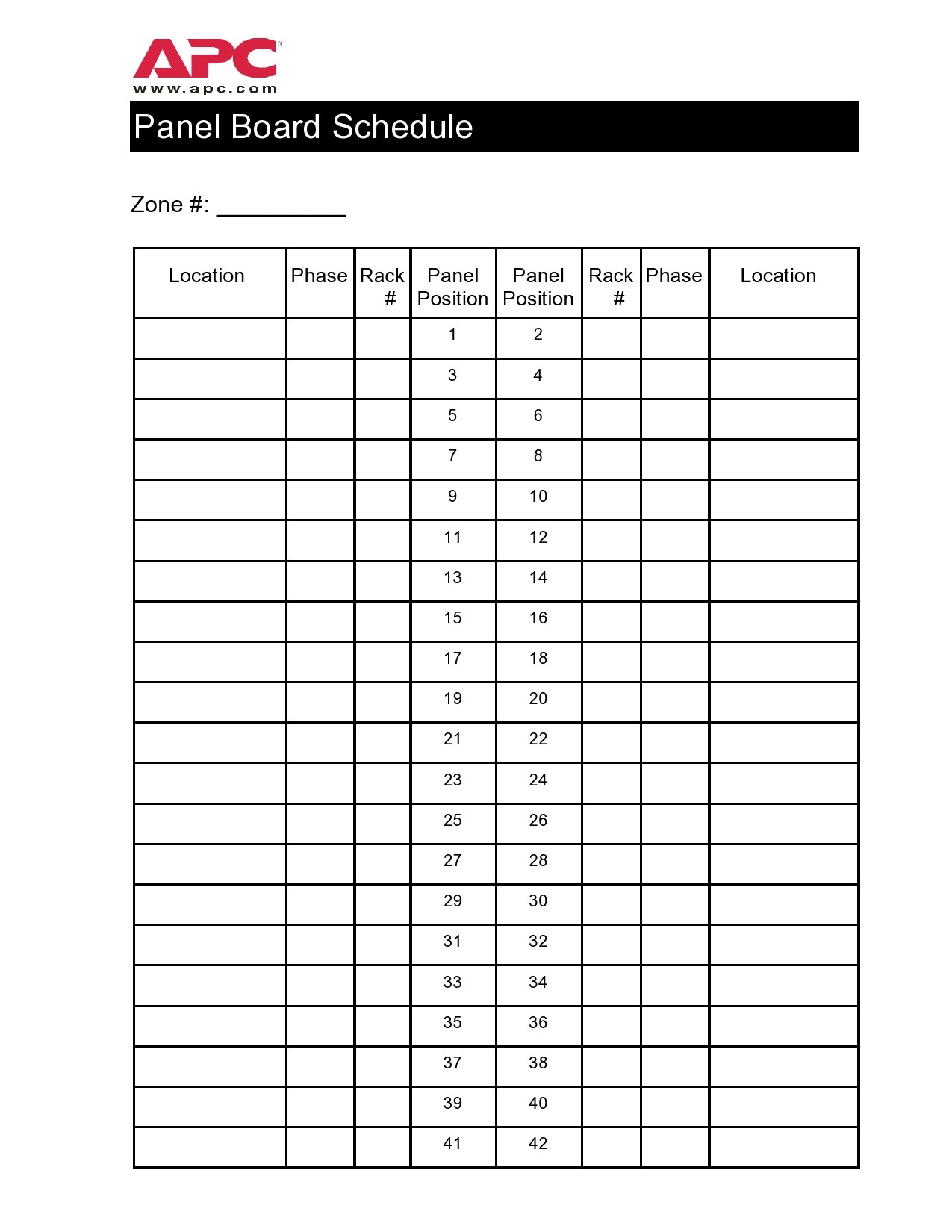

Fillable Panel Schedule Templates

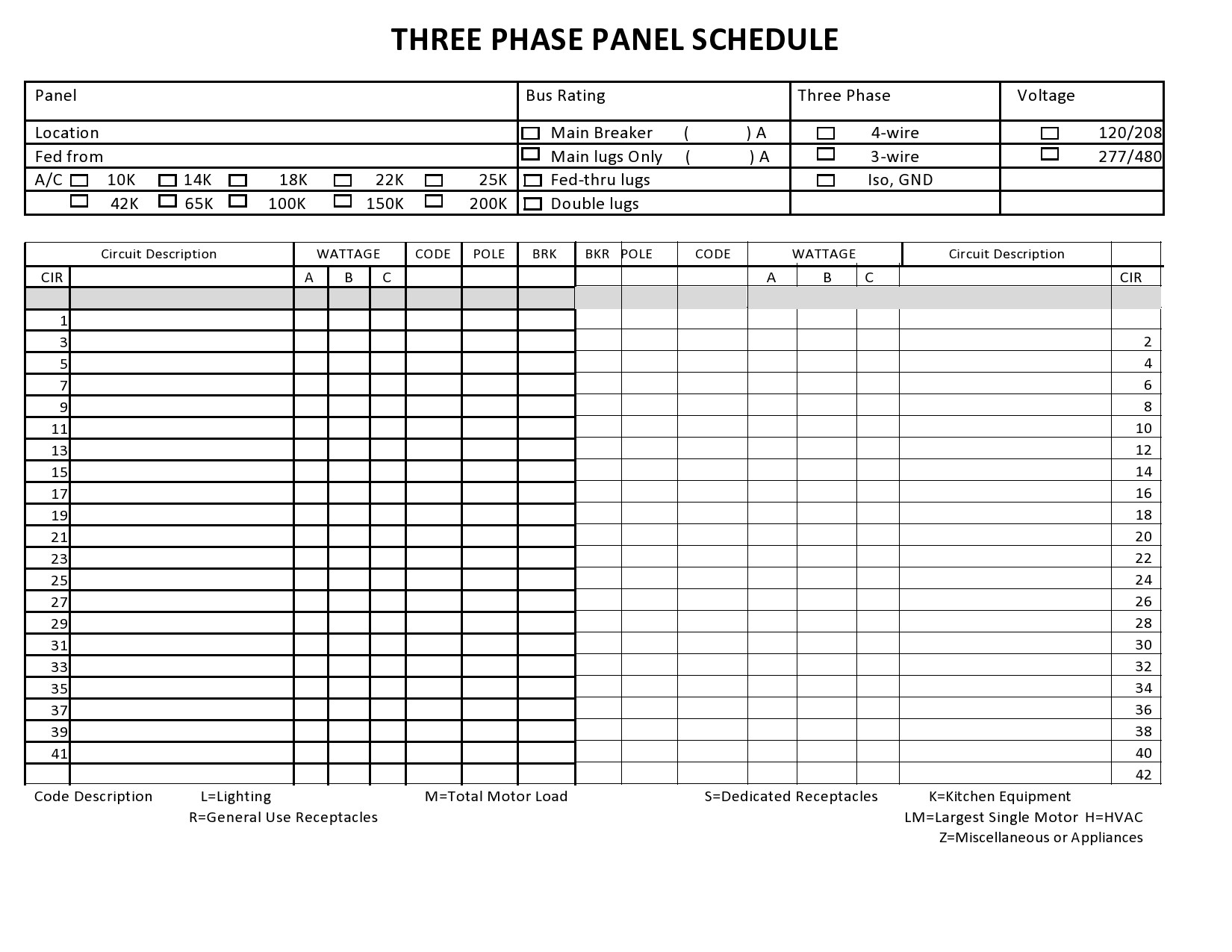

Types of electrical panel schedule templates

There are three main types of electrical panel schedule templates as follows.

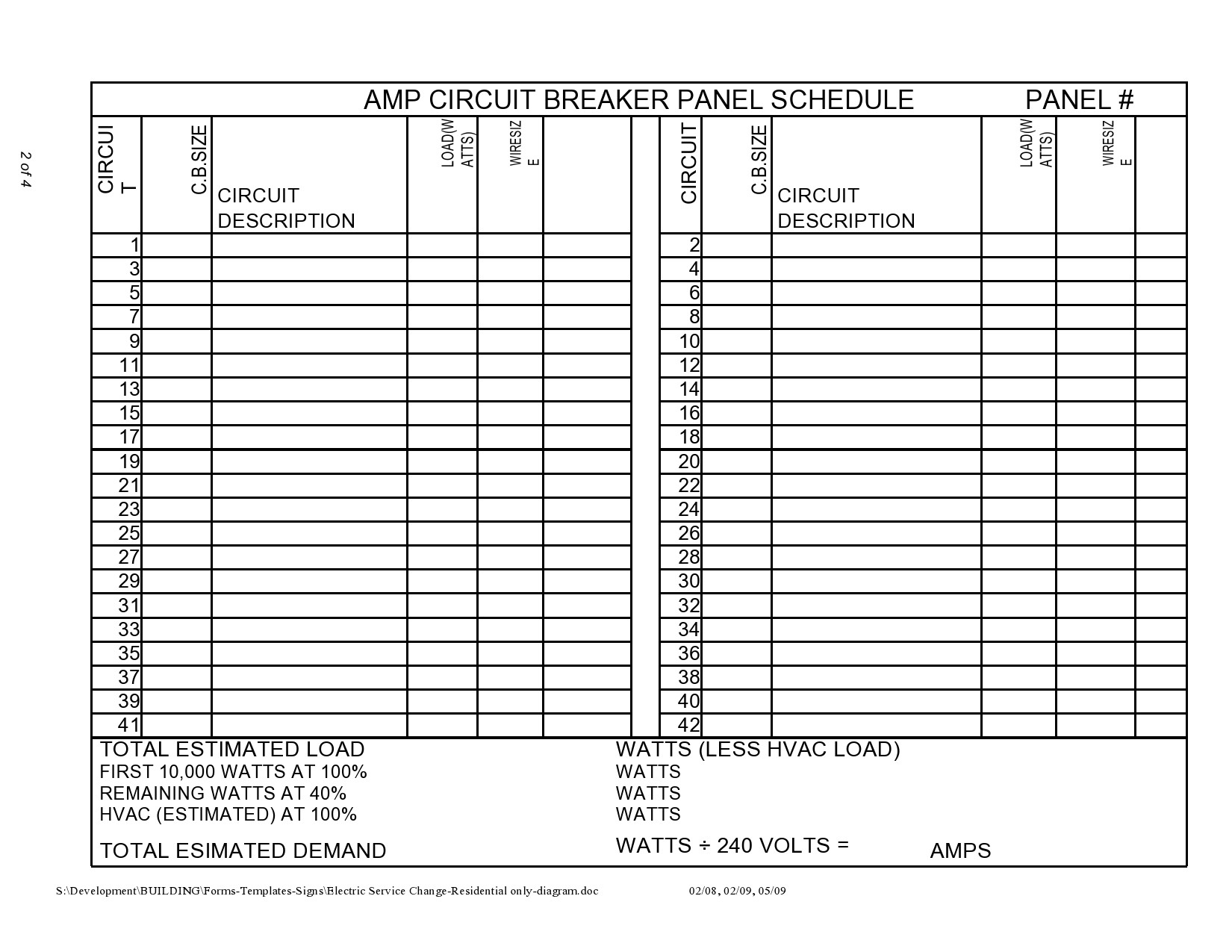

Branch panel schedule

This is an electrical panel schedule template that is used with a panel board device. A branch panel has three types of templates that can be configured for different uses.

- One column panel schedule

- Two columns’ circuits across the schedule

- Two columns circuit down schedule

Data panel schedule

It is a panel template used with a data panel device. It is used for identifying circuits and data outlets. Devices that can be connected to a power panel are security alarms, fire alarms, phones, etc.

Switchboard panel schedule

It is a panel used with switchboards. It shows details of the panel boards connected to a switchboard.

What do process and non-process loads mean?

When supplying electrical loads during power installation, you will create two types of electrical loads that are controlled by the load schedule. A processing load is a load that relates directly to a building. They are mostly connected with a building’s mechanical equipment. These are loads such as

- Heaters

- Motors

- Conveyors

- Compressors

These loads are not on duty all the time but the moment they are switched on, they consume a lot of power. Sometimes it can help a company save more money if they choose process loads that are energy saving. They require thicker wires because they require more voltage and amperes to run or work.

Non-process loads

These are the loads that help make the building habitable. Without the non-process loads, it might be impossible to work or live in such a building. These are loads such as the control system, HVAC, utility system, lighting, fire safety, etc.

These are loads that are on duty all the time but compared to process loads, they consume lesser power. However, the cumulative power they consume in a month can make the bills soar high.

Absorbed power

Each load will draw a certain amount of power anytime it is switched on. When that drawn power is calculated, it is what is called absorbed power. Since you cannot readily get the amount of absorbed power drawn by the device, it is usually calculated at a percentage between 80% to 90%.

Efficiency

Efficiency is determined by how well an electrical gadget works. It is affected by the amount of electricity it receives and the amount that is changed into mechanical energy. In most cases, the efficiency of a load ranges between 80-95%. The rest of the power is lost as heat.

Power factor

It is not every portion of a panelboard that shall be reactive all the time. Mostly, only a portion of the board shall be reactive at any given time. The reactive portions versus the non-reactive portions are what is called the power factor. It is mostly measured as per each individual load.